Mercedes-Benz Guard

Stars with a hard shell

Stuttgart – With seven Guard models, Mercedes-Benz offers the widest ex factory range of special protection vehicles in the world.

This range has models from the S, E and G-Class, and continues the unrivalled tradition of the world’s oldest automobile manufacturer in the production of armoured vehicles.

In 1928 Daimler-Benz was the first manufacturer to offer specially protected vehicles ex factory.

The current Guard versions mainly differ from the standard models in having an intelligent, tailor-made structure of protective elements made from special steel and aramid fibre.

This protection cannot be seen from outside and is not subsequently installed in an already completed vehicle, but rather integrated into the bodyshell right from the start in a special production process.

This enables the body structure and running gear to be specifically adapted for the higher weight caused by the protective elements at the outset.

Apart from the build quality expected of a Mercedes, the Guard models retain the outstanding ride comfort and superior driving characteristics of the standard models.

The aim of the Guard models from Mercedes-Benz is to protect the occupants from violent criminal acts.

Neither is it only government ministers and top managers who are under threat nowadays, as drivers in many regions of the world do not feel safe from acts of violence.

Mercedes-Benz has the answer to violent attack with its armoured Guard models from the S, E and G-Class.

The flagship of the Mercedes-Benz Guard portfolio is the S 600 Pullman Guard, a prestigious state limousine with an opulently spacious and luxurious interior.

Depending on the customer’s requirements, the Guard models are resistant to handgun and rifle fire, and also certain explosives, while offering their occupants outstanding comfort and day-to-day practicality.

Mercedes-Benz S-Guard

The Mercedes-Benz S 600 Guard is the armoured, special protection version of the long-wheelbase Mercedes-Benz S 600.

The generous spaciousness of this flagship model, which offers all its occupants a first-class ambience, outstanding ride comfort and superior driving characteristics, is almost fully retained in the Guard version.

Naturally the S 600 Guard is also equipped with the technical innovations that have made the Mercedes-Benz S-Class the benchmark for the entire field of car development, and the world’s best-selling luxury saloon.

The S 600 Guard is powered by a twelve-cylinder biturbo engine developing 380 kW (517 hp). It provides highest protection to level VR6/VR7.

Mercedes-Benz S 600 Pullman Guard

The S 600 Pullman Guard continues the tradition of Mercedes-Benz state limousines, and treats it occupants to generous spaciousness and outstanding comfort.

This interior spaciousness is ensured by a further, 115-centimetre increase in the wheelbase compared to the long-wheelbase version of the S‑Class with special protection, to 4315 millimetres.

The state limousine also has a raised roof section at the rear for even easier access and more headroom.

Four passengers can be seated behind a partition in the rear, on comfortable, opposing seats in line with Pullman tradition.

This allows plenty of space for confidential discussions. All the important communication and entertainment functions are on board as well.

The Pullman is likewise powered by the silky-smooth twelve-cylinder biturbo engine with a cubic capacity of 5513 cc, which develops 380 kW (517 hp) and an impressive torque of 830 Nm.

The S 600 Pullman Guard has highest protection to level VR6/VR7.

Mercedes-Benz E-Guard

The Mercedes-Benz E-Guard models are available in three engine variants.

The six-cylinder diesel unit in the E 350 CDI BlueEFFICIENCY Guard develops 195 kW (265 hp) and 620 newton metres of torque.

The V6 petrol engine in the E 350 Guard has an output of 200 kW (272 hp).

The most powerful variant is the 5.5-litre V8 in the E 500 Guard, which develops 285 kW (388 hp).

Because of the run-flat tyres which are standard for all E-Guard models, their top speed is limited to 240 km/h.

All E-Guard models have high protection to level VR4. Their occupants enjoy the same generous spaciousness and high ride comfort as in the standard models.

Mercedes-Benz G 500 Guard

The Mercedes-Benz G-Class is also available in a special-protection version. The G 500 Guard is equipped with a 5.5-litre V8 engine and highest protection to VR6 or VR7.

Integrated special protection for outstanding safety

Specialists in Sindelfingen with many years of experience in this field apply the principle of integrated special protection to the Mercedes-Benz Guard models.

In effect this means that, rather than retrofitting the protective elements in the doors, rear wall, side panels, roof lining and firewall etc. of an already finished vehicle, they fully integrate them into the bodyshell in a dedicated production process.

This effectively creates a coat of armour around the entire passenger cell. Even the roof frame struts, door locks, door gaps, exterior mirror mountings and other components are incorporated into this security concept.

The resulting vehicle offers hallmark Mercedes-Benz build quality combined with comprehensive high/highest protection characteristics, even in those areas where retrofitting would be all but impossible.

A further advantage of integrated special protection is that the protective features actually reinforce the body structure rather than imposing extra stresses.

In addition, Mercedes-Benz’ integrated design approach means that any body-structure reinforcements required due to the weight of the protective elements can be integrated right from the very start.

The result is extraordinary longevity and the same exceptional quality all round that distinguishes standard Mercedes-Benz production models.

All Mercedes-Benz Guard models display the same outstanding ride comfort and effortlessly superior handling as their series-production counterparts.

Furthermore, generously dimensioned suspension components and brakes ensure that their handling qualities are almost on a par with those of the standard-production models, thus giving the driver an optimal driving feel with high dynamic reserves at all times.

The chassis is also designed to provide hallmark Mercedes ride comfort despite the extra weight.

The basis for this is the long-standing, continuous and close cooperation with nationally and internationally recognised security authorities.

For decades, this has ensured that the Mercedes specialists have been able to continuously increase their expertise in the fields of development and manufacturing while also applying their vast experience in vehicle protection technology and ballistics to meet the highest standards.

Thanks to the seamless integration of the special protection features, the paint quality and corrosion protection match the standards of Mercedes-Benz series-production vehicles.

Moreover, the Guard models can be serviced in any Mercedes-Benz service outlet anywhere in the world – another important factor which ensures easy access to comprehensive service of the highest standard.

Mercedes-Benz uses this know-how acquired over many years to provide answers to different risk scenarios all over the world, offering Mercedes-Benz Guard models with various protection levels in accordance with the European standard.

- High-Protection vehicles, engineered to the VR4 protection level, resist large-calibre revolver ammunition and offer particularly good protection against the increasing threat of drug-related and violent street crime.

- Highest-Protection vehicles, engineered to protection level VR6/VR7, provide effective protection against the threat posed by terrorist attacks. Their armour is designed to resist rifle-fire from military weapons, which has a velocity almost twice that of handgun bullets. They also offer resistance to shrapnel from hand grenades and explosive charges.

More than 80 years of factory-integrated special protection

As the inventor of the automobile, the world’s oldest automobile manufacturer has always seen itself obligated to develop automotive technology further at the highest level, and to set constantly new standards.

This applies in equal measure to the special protection vehicles – as witness the unique tradition on which the Stuttgart-based premium brand can also look back in this sector.

As early as 1928, with the model Nürburg 460, Daimler-Benz was the first company to start building saloon cars with factory-fitted protective features which effectively shielded the occupants from attacks using firearms and explosives.

This was followed by more than eight decades of extensive material testing and systematic development which has secured the exceptional position of Mercedes-Benz in the field of special protection to the present day.

In the 1930s and 1940s, the specially protected Mercedes-Benz Nürburg 460 was followed by armoured versions of the “Grand Mercedes” model 770, and of the 500 and the 540 K.

In September 1963, Mercedes-Benz presented a new, exclusive prestige vehicle – the legendary 600 model – to meet the requirements of the most demanding customers.

Shortly after the launch, the German government approached Daimler-Benz with a request for an armoured version for state visitors.

For the engineering team in Stuttgart, this marked the beginning of a new era characterised by a new set of challenges – not least, how to reconcile the requirements of a special-protection vehicle with a self-supporting body structure which had by now become the industry norm.

With no other German manufacturer at the time able to offer factory-built armoured passenger cars, and Mercedes-Benz limousines being held in high esteem by many governments around the world, a close working relationship developed between Daimler-Benz and the German authorities.

In the course of this cooperation, the Stuttgart-based automaker came up with many new technical solutions and concepts.

Indeed, this intensive cooperation formed the basis for the current European standards which define the different protection levels.

In 1970, when there was suddenly great demand for special-protection vehicles following attacks on diplomats in Latin America, Daimler-Benz rose to the occasion with armoured versions of the 280 SEL 3.5 model.

Demand grew once again during the 1970s with the attacks by the RAF terrorist group.

Mercedes-Benz therefore built special-protection variants of the eight-cylinder 350 SE, 350 SEL, 450 SE and 450 SEL models which it supplied to a select group of customers, including official bodies and governments in Europe and beyond.

All subsequent generations of the S-Class have also been available as special-protection variants.

Mercedes-Benz Guard safety philosophy

Licenced to protect

- Seven Guard models in the E, S and G-Class

- Dedicated production process

- A wealth of fully reinforced components

- Same high standard of Mercedes quality as standard-production models

- Sophisticated high-tech materials

With its Guard models, Mercedes-Benz offers the world’s widest ex-factory range of special protection vehicles.

The range comprising E-Guard, S-Guard and G-Guard features tailor-made protection to European standards.

A high level of protection is provided by armour made from state-of-the-art materials such as glass/plastic composites and high-strength special steel in combination with plastic elements.

All protective elements are incorporated at the bodyshell stage during a separate and independent production process.

Mercedes-Benz S 600 Guard

The armoured special-protection version of the long-wheelbase Mercedes-Benz S 600 is powered by a twelve-cylinder biturbo engine developing 380 kW (517 hp), delivering an outstanding performance that allows rapid escape and evasion in threatening situations.

The S-Class interior space concept, which makes for a first-class ambience combined with outstanding ride comfort for all the occupants, not to mention effortlessly superior handling, remains virtually uncompromised.

Furthermore, generously dimensioned suspension components and twin-calliper front brakes lend the Mercedes-Benz S-Guard saloon hallmark Mercedes handling qualities and provide the driver with an optimal driving feel at all times.

Furthermore, the suspension has been configured so as not to impair the sumptuous level of comfort that distinguishes the standard-production S-Class.

The Mercedes-Benz S 600 Guard offers highest protection to level VR6/VR7, as tested and certified by state-approved organisations.

Additional safety features include run-flat tyres, a self-sealing fuel tank and a fire-extinguishing system.

The Mercedes-Benz S 600 Guard is equipped with the same technical innovations that have made the flagship Mercedes S-Class the number-one trailblazer in passenger car development and the world’s best-selling luxury saloon.

These include Brake Assist PLUS and the PRE-SAFE® brake in combination with DISTRONIC PLUS, Night View Assist and PRE-SAFE® preventive occupant protection with additional functions.

Moreover, the outstanding level of interior comfort and agile handling make for an effortlessly superior driving experience.

S 600 Pullman Guard

With the prestigious S 600 Pullman Guard luxury limousine with integrated highest protection to level VR6/VR7, the world’s oldest automaker is continuing a unique tradition of large, armoured prestige limousines.

It was 80 years ago that Mercedes-Benz became the very first car brand to develop and manufacture Pullman limousines with special protection features.

Like the famously luxurious and spacious open-plan Pullman railway coaches after which it is named, the S 600 Pullman Guard treats its occupants to a travelling environment characterised by generous accommodation and the highest comfort.

The vehicle owes its remarkably spacious interior to its 4315‑millimetre wheelbase, which is 115 centimetres longer than that of the long version of the special-protection S-Class.

Indeed, with an overall length of 6356 millimetres, the S 600 Pullman Guard is a vehicle of truly majestic proportions which offers its passengers not only a maximum of comfort, but also a superbly appointed setting for discreet meetings, equipped, of course, with all the key communications and entertainment systems.

This ensures that the occupants remain fully in touch while enjoying the luxury and comfort of their own, special environment.

With exotic wood trim and high-grade leather, the interior of the Mercedes-Benz S 600 Pullman Guard shows stylish elegance and perfect finish in every detail.

The standard individual rear seats in a V12 design ensure outstanding seating comfort. They are equipped with massage, multicontour and ventilation functions.

Another example of the luxurious appointments is the thermostat-controlled refrigerated compartment in the console between the rear seats, which is included as standard.

The technical basis for the Pullman limousine is the S 600 Guard, the flagship Mercedes-Benz Guard model.

It is powered by a silky-smooth twelve-cylinder biturbo engine with a cubic capacity of 5513 cc. Output is 380 kW (517 hp), with an impressive 830 Nm of torque.

The suspension and basic vehicle structure have been modified, as it would be impossible to guarantee the long-term overall stability of the vehicle with its extra-long wheelbase if the lengthening process consisted of simply inserting an additional body section.

The modifications also provide a solid foundation for the integration of the heavy special-protection elements.

Furthermore, the state limousine is equipped with a higher rear roof for easier access and greater headroom.

Four passengers can be accommodated in the rear compartment behind the partition – in comfortable seats whose face-to-face arrangement recalls the great Pullman tradition.

Mercedes-Benz E-Guard

The E-Guard is available in three engine variants, with an option of the basic ELEGANCE line or the AVANTGARDE line.

The E 500 and E 350, as well as the diesel-powered E 350 CDI BlueEFFICIENCY, are designed as five-seaters with a boot capacity of 540 litres and a high payload of up to 550 kilograms, which means they are fully suitable for day-to-day and family use.

The six-cylinder diesel unit in the E 350 CDI BlueEFFICIENCY Guard develops 195 kW (265 hp) and 620 newton metres of torque.

The V6 petrol engine in the E 350 Guard has an output of 200 kW (272 hp). The most powerful variant is the 5.5-litre V8 in the E 500 Guard, which develops 285 kW (388 hp).

Because of the run-flat tyres which are standard for all E-Guard models, their top speed is limited to 240 km/h.

The suspension and brakes are adapted to suit the increased weight caused by the protection features.

The E-Guard is equipped with a special Level II version of the AIRMATIC air suspension system as standard.

The electronic control and restraint systems that assist the driver in critical situations have been specifically adapted to suit the different parameters versus the standard model.

The car is fitted with 17-inch wheels and run-flat tyres designed for a maximum speed of 240 km/h as standard.

With the tyres deflated, the vehicle is still able to cover up to 80 kilometres at a speed of 80 km/h to enable its occupants to escape from the danger area in the event of a corresponding attack.

All E-Guard models are equipped with high protection to level VR4. Despite the high level of special protection, the comfort-related advantages of the E-Class are fully retained.

This applies equally to the generous spaciousness of this fully-fledged five-seater, the spatial acoustics, the sun protection and the lighting/control functions.

The rear window is heated, and the power windows on the driver and front passenger sides are fully retractable. Efficient power windows are also available for the rear.

Optional extras include an emergency alarm system that causes the headlamps to flash and sounds an alarm at the touch of a button in the event of a threat.

An intercom system allows communication between the protected passenger cell and the outside world.

In addition the E-Guard features the numerous, innovative assistance systems of the E-Class.

Mercedes-Benz G 500 Guard

The Mercedes-Benz G-Class is also available in a special protection version. The G 500 Guard can be supplied with protection level VR6 or VR7.

It is powered by a 5.5-litre V8 engine with 285 kW (388 hp) and a Touchshift 7‑speed automatic transmission.

The current Mercedes-Benz Guard models at a glance

| Protection level(European standard) | Cyl. | cc | kW/hp | Nmat rpm | km/h* | |

| E 350 CDI BlueEFFICIENCY Guard | High protection (VR4) | V6 | 2987 | 195 kW/265 hp | 620 at 1600 | 240 |

| E 350Guard | High protection (VR4) | V6 | 3498 | 200 kW/272 hp | 350 at 2400 | 240 |

| E 500Guard | High protection (VR4) | V8 | 5461 | 285 kW/388 hp | 530 at 2800 | 240 |

| S 600Guard | Highest protection (VR6/VR7) | V12 | 5513 | 380 kW/517 hp | 830 at 1900 | 210 |

| S 600 Pullman Guard | Highest protection (VR6/VR7) | V12 | 5513 | 380 kW/517 hp | 830 at 1900 | 160 |

| G 500 Guard | Highest protection (VR6) | V8 | 5461 | 285 kW/ 388 hp | 530 at 2800 | 160 |

| G 500 Guard | Highest protection (VR7) | V8 | 5461 | 285 kW/ 388 hp | 530 at 2800 | 160 |

* limited by tyres

Factory-integrated special protection for comprehensive safety

All special protection vehicles from Mercedes-Benz follow the principle of integrated special protection.

In effect this means that, rather than retrofitting the protective elements in the doors, rear wall, side panels, roof lining and firewall etc. of an already finished vehicle, they fully integrate them into the bodyshell in a dedicated production process.

This effectively creates a coat of armour around the entire passenger cell. Even the roof frame struts, door locks, door gaps, exterior mirror mountings and other components are incorporated into this security concept.

Only the integrated protection concept allows highly effective detailed solutions of this kind and enables Mercedes-Benz Guard models to offer such complete protection.

Specialists see to it that any potential weakspots are fully protected: at gaps in the body, at the doors or at the joins between metal and glass sections, an ingenious, overlapping system prevents projectiles from penetrating the interior.

Hence Mercedes-Benz Guard vehicles provide their occupants with seamless all-round protection.

High Protection or Highest Protection is combined with hallmark Mercedes-Benz build quality, even in those areas where post-production access would be all but impossible.

A further advantage of integrated special protection is that the protective features actually reinforce the body structure rather than exerting extra strain.

In addition, Mercedes-Benz’ integrated design approach means that any body-structure reinforcements required due to the weight of the protective elements can be integrated right from the very start.

These reinforcements include suspension mountings or sturdier door hinges and window frames, for example.

The window frames support the special side windows which are coated on the inside with a tough polycarbonate layer, while the hinges have to support doors whose weight is increased to over 150 kg on account of their special-protection features.

Despite this extra weight, the hinges operate smoothly and reliably for the entire lifetime of the car.

The result is extraordinary longevity and the same exceptional quality all round that distinguishes Mercedes-Benz standard-production models.

All Mercedes-Benz Guard models display the same outstanding ride comfort and effortlessly superior handling as their series-production counterparts.

Furthermore, generously dimensioned suspension components and brakes ensure that their handling qualities are almost on a par with those of the standard-production models, thus giving the driver an optimal driving feel with high dynamic reserves at all times.

The chassis is also designed to provide hallmark Mercedes ride comfort despite the extra weight.

Thanks to the seamless integration of the special-protection features, the paint quality and corrosion protection also match the high standards of conventional Mercedes-Benz passenger cars.

And needless to say, all Guard models can be serviced in any Mercedes-Benz workshop anywhere in the world, and come with full warranty cover.

Combination of high-tech materials

For a high level of protection, the passenger cells of Mercedes-Benz Guard vehicles are clad in armour made of state-of-the-art materials such as glass/plastic combinations, high-strength special steel or special steel-and-plastic composites.

Mercedes engineers use high-alloyed special steels and are constantly researching new materials to determine the optimal degree of protection for each particular resistance level.

They do this on an in-house firing range equipped with a laser measuring system.

This commitment to exploring the potential of new materials and technologies has made Mercedes-Benz the number-one trailblazer in the field of special-protection vehicle development – a position it has held for several decades.

The experts’ aim is to reconcile the highest degree of protection with the lowest possible weight.

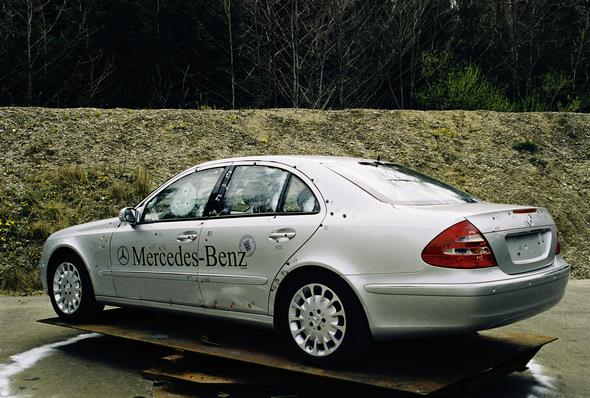

Armour that is invisible from the outside

On the outside, there is hardly any difference at all between a Mercedes-Benz Guard saloon and its standard-production counterpart.

That’s because, when it comes to special protection, discretion is just as much of a must as trust, reliability and quality. Statesmen, diplomats and senior business figures all over the world appreciate being able to travel incognito in vehicles that do not immediately betray their special status.

But even those customers who are less in the public spotlight realise that discretion is the best form of protection.

And because the protective elements in Mercedes-Benz Guard models are already integrated into the bodyshell, they not only offer extremely effective protection, they are also inconspicuous in everyday life.

Nobody actually sees the hard core that lies within.

Development, testing and production

Safety is always the top priority

- Development starts at an early stage

- Special solutions for special-protection vehicles

- Extensive trials on test rigs and on the road

- Produced by hand-picked specialists

Mercedes-Benz engineers always start thinking about safety at a very early stage. And the developers of the armoured special-protection models that go by the name of Mercedes-Benz Guard are no different.

Their work begins with the specifications book as long as two years before the first pilot-production model of the conventional, non-armoured series even takes shape.

At this early stage, special-protection development is based on the engineering design and production datasets which describe every last detail of the future model.

The engineers use this information to determine where the protective elements can be housed in the bodyshell. This is primarily a question of the available space.

Steel and plastic armour is installed so that it is inconspicuous and in no way diminishes the customer benefit delivered by the standard-production model – for instance, it has to be just as easy to get into the car, and the car must provide the same feeling of well-being and spaciousness.

The developers are equally meticulous in their approach when it comes to implementing design measures to compensate for the stresses caused by the extra weight of a special-protection vehicle.

The protective cell with its robust armour is a fully integral part of the car and, as such, allows the forces associated with the dynamic loads to which the vehicle is subject to be channelled into the armour plating via the wheels, bearings, axle components and body reinforcements.

In addition to this, maintenance and repair requirements have to be taken into account as early as the design stage, since workshop staff need easy access to all the vehicle’s major components despite the armoured shield around the car.

The special-protection developers also consider how they can use series production processes appropriately, but for individual components they also take their own approach if standard parts cannot meet their requirements.

For the Mercedes-Benz S 600 Pullman Guard, the developers designed some 550 new components made from steel alone. Then there are numerous plastic and glass components.

They all join together with the bodyshell of the Pullman to create a fully-enclosed cell which is self-supporting and therefore further reinforces the vehicle.

This is one of the main reasons behind the vehicle’s outstanding durability and longevity.

Stress on the test rig

One thing the Mercedes-Benz special-protection experts are keen to avoid is a reliance on theory.

This is why they fully check the design measures under realistic conditions, subjecting the Guard models to an extensive series of in‑house tests.

The vehicles are checked on test rigs using specially selected products and placed under extreme loads so that even the slightest flaws are inexorably detected and remedied.

The hydropulse rig, for example, is used to test ride comfort, active safety and durability. Here the methods applied constitute nothing but pure stress for the vehicles on test.

Their wheels are positioned on four hydraulically operated cylinders which simulate torture-track vibrations.

These cylinders can also make the wheels vibrate at random or imitate sudden collisions with sharp-edged objects.

The aim of all this is to determine the correct configuration for optimal road contact and, therefore, optimal active safety.

Meticulous optimisation of the tiniest details is also part of the programme, including fine‑tuning of the shock absorbers and axle mounts.

In the hot- and cold-air tunnels, on the other hand, all that matters is temperature.

Wind speeds of up to 100 km/h, temperatures as high as 50 degrees or as low as minus 30 degrees Celsius and 100-percent relative humidity add up to create a hellish climate, the like of which most places on earth reachable by road never even experience.

Here the aim is to ensure optimum passenger comfort even under the most extreme of climate conditions.

Further simulations are performed to make sure that external factors cannot interfere with the vehicle’s electronic systems, and that the vehicle acoustics are of the usual high Mercedes standard.

Yet the old adage still applies: the sternest challenge is everyday life. This is why Mercedes-Benz Guard models undergo hundreds of thousands of kilometres of testing in practically every corner of the world, the aim being to verify their practicality in all conceivable climate conditions and road or traffic scenarios.

They are driven on the most atrocious surfaces, continuously bounced over a series of obstacles and plunged mercilessly into deep potholes.

They also have to endure extreme manoeuvres during test and trial drives on the Grossglockner mountain pass, on cordoned-off test tracks or in the sweltering heat of Laredo in Texas.

All in the name of optimising steering comfort and fine-tuning the suspension, brakes and electronic control systems.

Mercedes-Benz Guard production: predominantly by hand

Guard models are the result of a sophisticated production network combining regular production and a dedicated, separate Guard production line.

The bodyshell of the S-Guard therefore receives its exterior contours in series production quality, with the utmost dimensional precision, in the fully automated series production process, while the protective elements are created in the dedicated workshops.

This is where selected specialists assemble the special protection vehicles from Mercedes-Benz, mostly by hand.

This begins with the production of the many hundreds of steel elements for the Guard models.

Working to a pattern, an engineer uses a 3000-bar water jet to cut each part from sheets of high-alloyed special steels of varying sizes and thicknesses, which have been continuously enhanced over a period of several decades.

Shaping these steel components requires an immense degree of feel and vast experience in the handling of hard, ductile special steels which can often prove extremely challenging during this process.

Experts who are familiar with every last detail of the steel’s structure, and who use this knowledge in every step of the process, man special presses equipped with in-house-developed bending and shaping tools.

Here every tenth of a millimetre counts as there is so little installation space available in the car. They carefully start bending the material to shape, meticulously check the initial result using specially produced gauges and then continue shaping the material until they are satisfied with the result.

Some components are welded together by hand to form larger subassemblies which are then heat-treated in their entirety.

This process radically alters the steel’s structure, making the steel impossible to bend. Only then does it fulfil the stringent ballistic requirements.

After this, specialists install the protective components in the bodyshell. Specially trained Guard fitters then get to work again to reinforce the entire basic structure of the vehicle.

This reinforcement process takes in the vehicle floor, the suspension mountings, brackets for the floor armour, covers for the tunnel area and other components.

In between each stage of production, the Guard components repeatedly pass through strict in-house checkpoints for quality-control purposes.

Finally the bodyshells are returned to the series-production line to be painted in accordance with stringent Mercedes-Benz paint-quality and corrosion-protection standards.

After the paintwork has been applied, the engine, chassis components and interior are fitted – painstakingly by hand once more.

Only then is the passenger cell fully protected. And only then does it meet the characteristically high Mercedes quality standards.

Special-protection target groups and markets

Mercedes-Benz Guard models are used around the world to counter acts of violence

- Mercedes-Benz Guard models are highly regarded

- Two resistance levels for differing requirements

- Demand for special-protection models is growing around the world

Violent crime has become a fact of life. And car occupants are all too often the targets.

This is borne out by statistics which show an increase in gang-based crime, armed robberies and carjacking.

For many years now, heads of state, leading diplomats and top managers have only ventured out onto the road in armoured cars.

Even motorists who are far less in the public spotlight admit to feeling unsafe at times.

Mercedes-Benz has the answer to violent attack with its armoured Guard models. Depending on the customer’s requirements, the Guard models are resistant to handgun and rifle fire, and also certain hand-grenades and explosives, while offering their occupants outstanding comfort and day-to-day practicality.

Vast experience breeds trust and confidence

The Mercedes-Benz Guard models with factory-integrated special protection are very highly regarded.

This is underlined by the fact that some 6000 of the Stuttgart-based brand’s special-protection vehicles are in use around the world today, including some models which were built 20 years ago.

The high esteem in which the armoured vehicles displaying the Mercedes star are held, and the trust people place in them, is the product of many years of hard work.

“We take our customers’ requirements seriously and have been continuously developing and enhancing our special-protection vehicles ever since the first model was built 80 years ago”, says Markus Rubenbauer, head of Mercedes-Benz Guard sales.

The basis for this is long-standing, close cooperation with nationally and internationally recognised security authorities. This ensures that the Mercedes specialists are always fully briefed on the latest security requirements, and are able to consolidate their position at the leading edge of vehicle protection technology and ballistics.

This is why the Mercedes-Benz Guard models are universally acknowledged for their high standards of safety and security.

Mercedes-Benz offers a choice of high protection or highest protection

Mercedes-Benz uses this know-how acquired over many years to provide answers to different risk scenarios, offering Mercedes-Benz Guard models with various protection levels (VR = Vehicle Resistance) in accordance with the European standard:

- High-Protection vehicles, engineered to the VR4 protection level, resist large-calibre revolver ammunition and offer particularly good protection against the increasing threat of drug-related and violent street crime.

- Highest-Protection vehicles, engineered to protection level VR6/VR7, provide effective protection against the threat posed by terrorist attacks. Their armour is designed to resist rifle-fire from military weapons, which has a velocity almost twice that of handgun bullets. They also offer resistance to shrapnel from hand grenades and explosive charges.

The Mercedes models in both protection categories have been developed in accordance with internationally recognised security standards and have successfully undergone both testing and certification by independent state organisations.

Key markets for special-protection vehicles

Demand for special-protection vehicles is rising and is currently especially high in Latin America, South Africa and southern Europe.

In these regions, most buyers opt for high protection vehicles (resistance level VR4).

In Central Europe and the former Soviet states, however, highest protection Guard models are more the norm (proection level VR6/VR7).

Further key markets for special-protection vehicles include the Near East, the Middle East and Asia.

Eight decades of Mercedes-Benz special protection

A unique tradition of building special-protection vehicles

- Armoured limousines for royalty and governments since 1928

- The special-protection 600 model was built in 1965 at the request of the German government

- Major role in the development of special-protection criteria

Mercedes-Benz has never seen any contradiction between innovation and tradition.

On the contrary, as the inventor of the automobile, the world’s oldest automaker has always felt a special obligation to drive forward the development of automotive technology at the highest level and to keep on setting new standards for the industry.

This demanding objective which Mercedes-Benz has set itself also applies to its armoured special-protection vehicles, as is demonstrated by the Stuttgart-based premium brand’s unique track record in this field.

As early as 1928, with a vehicle based on the Nürburg 460 model, Daimler-Benz became the first company to factory-fit vehicles with special protective elements designed to provide the occupants with effective protection against attack with firearms and explosives.

This was the start of eight decades of extensive materials testing, focused development and continuous improvement, during much of which Mercedes-Benz enjoyed a unique position in the field of special-protection vehicles and acquired a reputation as the specialist of choice in this field.

Following the Nürburg 460 model of 1928, Mercedes-Benz went on to develop special-protection variants of its successors in the luxury prestige segment – the 770 (W07) “Grand Mercedes” and the 500 model. Japanese Emperor Hirohito personally selected an armoured “Grand Mercedes” as a vehicle befitting his status – this limousine, which was delivered in 1935, can now be seen in the Mercedes-Benz Museum in Untertürkheim.

Many politicians and heads of state followed the Emperor’s example and placed their trust in Mercedes-Benz special-protection vehicles.

From 1965, Mercedes-Benz offered numerous special-protection models. The legendary Mercedes-Benz 600 in limousine and Pullman limousine guise was followed during the 1970s and 1980s by the 280 SEL 3.5 and a wide range of S-Class V8 models: the 350 SE/SEL and 450 SE/SEL, and then the 380 SE/SEL to 560 SEL models.

Since 1979, Mercedes-Benz has also built special-protection versions of the G‑Class. Today customers have a choice of protection levels in the E-Guard, G‑Guard, S-Guard and the Mercedes-Benz S 600 Pullman Guard.

The very first steel-reinforced limousines

The first special-protection models from Mercedes-Benz differed from those of later years not only with regard to their design and performance, but also in terms of their technical basis.

Instead of having a self-supporting body structure, which is now the norm, their bodies were mounted on strong frames.

The weight of the protective steel plates therefore called for less extensive design changes than is currently the case.

Model Nürburg 460, model 500 (W08)

This was also true of the very first Mercedes-Benz vehicle with factory-integrated special protection, the Nürburg 460 (W 08) of 1928, which has already been mentioned.

Unfortunately, there are no longer any documents which describe the technical details of this first special-protection vehicle.

All that is known, thanks to contemporary archive photographs, is that a Pullman limousine of this type built in 1931 was armoured with sliding steel plates which allowed the window areas to be shielded from the inside.

The windscreen was protected by a folding steel plate with only a small observation slit provided for the driver to see through when it was in use.

As for the passengers, a roof-mounted periscope allowed them to survey their surroundings when the protective plates were deployed.

A Pullman limousine version of a model 500 (W 08), a later variant of the Nürburg, is still in existence today.

The doors and windows of this vehicle, which was delivered to Japan in 1937, are protected on the basis of the same principles which apply today.

“Grand Mercedes” model 770 (W 07)

The next vehicle which Mercedes-Benz offered in a version with factory-integrated armour was the model 770 “Grand Mercedes” which was launched in 1930.

Notable characteristics of this model included rigid front and rear axles, which were attached to a ladder frame consisting of U-section‑profiles by means of semi-elliptical springs, as well as a 7.7-litre eight-cylinder in-line engine with an output of 150 hp (200 hp with a supercharger).

Between March 1932 and January 1935, the Japanese imperial court took delivery of at least six “Grand Mercedes” models in Pullman limousine guise.

At least one of them was armoured, and has been in the Mercedes-Benz Museum collection since 1971.

“Grand Mercedes” model 770 (W 150)

An enhanced version of the “Grand Mercedes” with a sophisticated swing-axle suspension was presented in 1938.

The perimeter frame of this model consisted of thin-section oval tubes which combined great rigidity with low weight.

Independent double-wishbone front suspension and‑a rear De Dion axle represented additional improvements.

The engine, the technical characteristics of which were largely based on the preceding model, developed 230 hp with a supercharger.

The “Grand Mercedes” was officially available as a Pullman limousine, as Cabriolet D and Cabriolet F models and as an open touring car.

A number of special armoured versions of each of these body variants were built.

Furthermore, the state commissioned armoured four-door limousines between June 1943 and July 1944.

Whereas the permissible gross vehicle weight of the standard cars was 4200 kg, this figure increased to as much as 5420 kg in the case of the armoured versions.

However, the maximum speed of the latter was reduced from 170 km/h to 80 km/h in order to maintain the service life of the tyres.

Model 540 K (W 29)

Featuring a greater displacement and higher power output, the elegant, luxurious and sporty 540 K was the successor to the 500 K.

Both models were aimed at a demanding, performance-oriented clientele and, as was usual at the time, were available in many different body variants – as saloons, roadsters, in various cabriolet versions and as open touring cars.

Moreover, two-door armoured saloon versions were built for the Reich Chancellery and delivered between November 1942 and February 1943.

At least one example of this two-door special-protection saloon survived the turmoil of the final years of the war and the immediate post-war period, and has been on show in the Technical Museum in Prague for many years.

Model 600 / 600 Pullman

In September 1963, Mercedes-Benz presented a new, exclusive prestige vehicle to meet the requirements of the most demanding customers – the 600 model which became an instant legend.

It was outstanding in every respect – generous dimensions, majestic design and exceptional technical characteristics.

Its V8‑injection engine developed 250 hp from a displacement of 6.3 litres and allowed the almost two-and-a-half-tonne vehicle to attain a top speed of more than 205 km/h with a 0 to 100 km/h acceleration time of ten seconds.

The standard-fit air suspension, whose shock absorbers could be adjusted from the steering column while the vehicle was moving, ensured excellent ride comfort.

The Type 600 was available as a five to six-seater limousine with a 3200 mm wheelbase and also in several Pullman variants with a wheelbase of 3900 mm.

It was only a short time after the launch of the top-of-the-range model that the German government asked Daimler-Benz AG to build an armoured version for state visitors.

Although Mercedes-Benz had a remarkable track record in building special-protection vehicles, this on its own was not enough as the technical fundamentals had changed dramatically, not least because of the adoption of the self-supporting body.

As a result, the engineers and materials experts at Mercedes-Benz embarked on nothing less than the reinvention of the concept of special protection.

Thus it was that a small team set out to develop a new approach. In May 1964, at the Sindelfingen plant, they conducted the first armour tests with new steel grades and prepared the first design drawings.

They eventually decided on high-alloyed steel grades, using double layers in certain situations and weight-saving ceramics for some flat-surfaced components.

At the same time, working with a glass manufacturer experienced in equipping banks, they came up with a solution for the windows, the vehicle requiring not only a curved windscreen, but a curved rear window, too.

In June 1965, a bullet-resistant Pullman limousine was produced – the first special-protection vehicle built by Daimler-Benz since the war.

Working under the pressure of an extremely tight schedule, the company managed to complete it just in time for the state visit of Queen Elizabeth II.

The armoured Pullman limousine had a raised roof element so that Her Majesty did not have to remove her hat.

This generous headroom subsequently benefited other state visitors, many of whom wore hats in those days.

To make it easier to open the doors, whose weight had increased dramatically because of the protective elements, the engineers installed a hydraulic system for the rear compartment.

It was activated at the touch of a small button housed in the door handle recess – security staff and hotel doormen were instructed accordingly.

Along with a number of “normal” Pullman limousines, this vehicle remained in the company’s fleet, ready to be hired to the government or other users when required.

A second version of this special variant was built in 1980. This, too, spent its working life in the company’s fleet before joining the Mercedes-Benz Classic vehicle collection.

On special request, Type 600 limousines and Pullman limousines were also built with special protection for private customers. Between May 1971 and November 1980, several special-protection 600 models were built.

However, unlike the two vehicles in the company fleet, these models had a standard-height roof.

Model 280 SEL 3.5

After the model 600, which was built as a one-off, Daimler-Benz initially gave no further consideration to the production of special-protection models.

This changed in 1970 when several diplomats in Latin America were attacked, kidnapped, and, in some cases, murdered.

The German foreign office felt it necessary to provide a number of its heads of mission with specially protected vehicles.

Several German federal authorities suggested that Daimler-Benz should build armoured vehicles as the comfortable, reliable and powerful limousines from Stuttgart were highly regarded by many governments – a reputation which had been established by the Type 300 – popularly known as the “Adenauer” – in the 1950s.

The result was the special-protection model 280 SEL 3.5, which was produced between May 1971 and September 1972.

Most of these vehicles were delivered to Germany’s foreign missions judged to be at particular risk, while the remainder went to governments and at-risk politicians abroad.

The 116 series S-Class Saloons

The attacks by the RAF terrorist group in the 1970s led to a sharp increase in demand for protected vehicles.

Daimler-Benz therefore decided that the all-new luxury-class generation – with the internal model-series designation W 116 – which was launched in September 1972 should also be offered in the form of a special-protection variant.

The company’s experts built on the experience they had acquired developing the special-protection 280 SEL 3.5 and improved the protection technology continuously.

The special-protection variants of the eight-cylinder 350 SE, 350 SEL, 450 SE and 450 SEL models were supplied to a select group of customers, including many government bodies in Europe and overseas.

In order to provide even greater protection from projectiles and explosives, the authorities and Daimler-Benz resolved to work together closely during the subsequent years – indeed, this relationship continues to this day – as no other German car manufacturer was able to offer special-protection vehicles at the time.

Together, they developed appropriate and feasible technical standards.

The Mercedes-Benz engineers began by testing individual components for their suitability. In the next phase, complete vehicles were tested by firing different types of ammunition at them in various conditions.

Finally, the vehicles were also subjected to testing with explosives. Daimler-Benz established its own firing range in 1983.

The results of these tests were used to prepare requirement profiles for different situations – examples being opportunistic crimes such as attacks while cars are waiting at traffic lights, robberies committed using small arms and terrorist attacks with military weapons.

This phase was conducted by the official ballistics authorities and Mercedes-Benz specialists who were responsible for many technical innovations.

These first technical descriptions formed the basis for today’s test regulations for the different resistance levels.

126‑series S-Class Saloons

Enhanced special-protection technology resulting from an intensive development programme was available for the new generation of the S-Class which was launched in 1979.

Particular mention should be made of two 500 SEL models which were built with a 200 mm longer wheelbase and a 30 mm higher roof element.

The first one, which was completed in January 1983, joined the company’s own fleet of prestige vehicles.

The second limousine was built at the request of the Vatican for the Holy Father and was presented to Pope John Paul II in August 1985.

140‑series S-Class Saloons

In March 1991 the 140 series was presented at the Geneva Motor Show as the successor to the 126 series, though the last examples of the 126 series with special protection were not completed until April 1992.

From February 1992 the 140 series saloons also became available with special protection – powered by a 5.0-litre V8 or 6.0-litre‑V12 engine.

The completely newly developed V12 was the first series-production twelve-cylinder car engine from Mercedes-Benz, and with a rated output of 300 kW (408 hp) it was also the most powerful Mercedes-Benz passenger car engine.

In a surprise move in September 1995, Mercedes-Benz unveiled the S 600 Pullman Guard which it had developed as a new state limousine with special-protection technology – the latest in a long tradition of such vehicles from Mercedes-Benz.

At 6213 mm long, this specially built model was exactly one metre longer than the long-wheelbase S 600.

The extra length benefited the rear passengers, who were accommodated on comfortable‑opposed‑seats and could separate their rear compartment from the driver’s area by means of a partition.

The 220 model-series S-Class

September 1998 saw Mercedes-Benz launch the 220 series S-Class Saloon. True to the company’s decades-long tradition, this generation of the S-Class had once again been designed as a large touring saloon with superior ride comfort, a high level of passive safety and effortlessly superior performance.

It differed from its predecessor principally in terms of its reduced exterior dimensions, a new, slimmer design and over 30 technical innovations which once again made the Mercedes-Benz S-Class the trailblazer for the whole spectrum of passenger-car technology.

From 2000 Mercedes-Benz also offered this S-Class generation with a long wheelbase and in several special protection versions.

These included the long-wheelbase versions of the S 500 and S 600 – both with highest protection (VR6/VR7). In 2004 the S 500 Pullman – also with highest protection (VR6/VR7) – was added to the special-protection models in this S-Class generation.

210‑series E-Class Saloons

Since 1995, Mercedes-Benz has offered special-protection limousines not only in S-Guard form but as E-Guard models too.

This variant is a response to the growing demand in the upper medium-size category, and meets the requirements of those customer groups whose members have a need for greater protection but wish to drive their vehicles themselves.

In order to deliver the desired performance despite the considerable additional weight of the protective elements, only the most powerful models were offered.

From March 1997, an additional version with lighter protection – with a VR4 protection level – was made available in order to offer a very large degree of protection from handguns.

This variant was also offered with a 3.2-litre V6 engine. As in the case of the vehicles with a VR6 resistance rating, the protective elements were integrated seamlessly into the body structure in the course of the production process.

These vehicles thus benefited from factory-integrated protection of a standard which is impossible to achieve by retrofitting special protection elements.

Current Mercedes-Benz Guard models

Shortly after its launch in 1979, the Mercedes-Benz G-Class model was also offered in a special-protection version.

Although it has undergone technical enhancements over the years, the G-Guard still forms part of the portfolio of Mercedes-Benz Guard special-protection vehicles – as do the S-Guard and E‑Guard models in their respective latest versions.

Entirely hand-crafted in the “Manufaktur”

Daimler-Benz had its first post-war special-protection vehicles built in the prototyping department as this offered the full range of facilities for the manufacture of one-off vehicles.

Specialists in modelmaking and bodyshell construction were to be found here, as well as experts in the fields of suspension systems, engines and vehicle electrics.

A paint shop and upholstery shop completed the line-up. As demand increased, these facilities were extended to form the current special-protection production line.

In order to meet many of the customer requirements – some of them quite out of the ordinary – the specialists crafted and assembled components entirely by hand.

A case in point was a vehicle built for the Pope on the basis of a W 126 S‑Class model. The biggest problem encountered in building this vehicle, which featured a sliding roof and a seat mounted on an extending pedestal, was presented by the need to drill holes in the C-pillars in order to attach the Papal emblem.

Normal steel drills were rendered useless because the interior of the pillar was reinforced with high-alloyed steel.

The workshop team eventually resorted to special tungsten drills but it still took two days to drill the fixing holes.

Russian presidents also presented the special-protection team with some difficult challenges. In 1997, for example, a special-protection S 600 Pullman was to be equipped with a Russian communications system.

However, the presence of the special-protection elements meant that only a limited amount of installation space was available – no more than ten centimetres between the boot lid and the equipment concerned.

Working with Russian engineers, the team was able to find a solution and deliver the vehicle to Russia on schedule.

Meeting other requirements – such as an extra-large ashtray, various entry aids, including wheelchair access systems, vehicles with running boards and roof handles for bodyguards – proved comparatively straightforward.

Eduard Shevardnadze, the former foreign minister of the Soviet Union and later President of Georgia, was so impressed by the work of the special-protection team that he wrote them a personal letter of thanks and enclosed a copy of his memoirs as a gift.

First-rate protection is sought-after on the second-hand market, too

For the sake of all its customers, Mercedes-Benz sells special-protection vehicles only after verifying the prospective buyer’s credentials. Great importance is attached to confidentiality.

Even when a new vehicle is being custom-built in the “Manufaktur”, the engineers and fitters are unaware of the identity of the customer on whose vehicle they are working.

Specially protected vehicles from Mercedes-Benz are very durable, with operating mileages of 400,000 to 600,000 kilometres not unusual.

The W 126 once used to carry the German Chancellor, and now in the Mercedes-Benz Classic vehicle collection, has covered more than 600,000 kilometres.

And in television reports from overseas countries it is still possible to see examples of the same model on official government business.

Even after many years on the road, Mercedes-Benz special-protection vehicles are often given a new lease of life.

After being returned to the factory and undergoing extensive refurbishment by specialists, they are almost like new and can be resold.

This is only possible because, rather than weakening the structure, the special protection components which were integrated in the bodyshell when the vehicle was originally built actually strengthen it.

Training for the driver

Anyone who uses special-protection vehicles needs to know how to handle them, as they are significantly heavier than their series-production counterparts.

This is why Mercedes-Benz, in addition to building and maintaining the vehicles, supports their drivers as well. Since 1993, the brand has offered every buyer of a special-protection vehicle a sophisticated driver training programme, during which the chauffeurs learn how to make optimum use of their cars in every situation.

The history of Guard vehicles: Mercedes passenger cars with special-protection features

| Year | Model series | Model designation |

| 1928 – 1939 | W 08 | Nürburg 460, Nürburg 500, model 500 |

| 1930 – 1938 | W 07 | “Grand Mercedes” model 770 |

| 1938 – 1943 | W 150 | “Grand Mercedes” model 770 |

| 1942 – 1943 | W 29 | 540 K |

| 1965 – 1981 | W 100 | 600, 600 Pullman |

| 1971 – 1972 | W 108 | 280 SEL 3.5 |

| 1973 – 1980 | W/V 116 | 350 SE/SEL, 450 SE/SEL |

| 1979 – 1992 | G 460 | 280 GE |

| 1981 – 1992 | W/V126 | 380 SE/SEL, 420 SE/SEL, 500 SE/SEL, 560 SEL |

| 1992 – 2000 | V 140 | 500 SEL/S 500 long-wheelbase, 600 SEL/ S 600 long-wheelbase |

| 1995 – 1999 | VV 140 | S 600 Pullman |

| 1996 – 2002 | W 210 | E 420 (VR6), E 430 (VR6) |

| 1997 – 2002 | W 210 | E 320 (VR4), E 430 (VR4) |

| 2000 – 2006 | V 220 | S 500 long-wheelbase (VR4), S 600 long- wheelbase (VR4) |

| 2000 – 2006 | V 220 | S 500 long-wheelbase (VR6/V7), S 600 long- wheelbase (VR6/VR7) |

| 2004 – 2006 | VV 220 | S 500 Pullman (VR6/VR7) |

| 2002 – 2009 | W 211 | E 320 (VR4), E 350 (VR4), E 500 (VR4), E 320 CDI (VR4) |

| 2006 – 2010 | V 221 | S 420 CDI (VR6/VR7) |

| Since 1999 | G463 | G 500 (VR6 and VR7) |

| Since 2006 | V 221 | S 600 (VR6/VR7) |

| Since 2008 | VV 221 | S 600 Pullman (VR6/VR7) |

| Since 2009 | W 212 | E 350 CDI BlueEFFICIENCY (VR4), E 350 (VR4), E 500 (VR4) |