Mercedes W218 CLS-Class 2010 –

European market launch in January 2011

The new CLS: refined sportiness

- More design: a new design language for the second generation

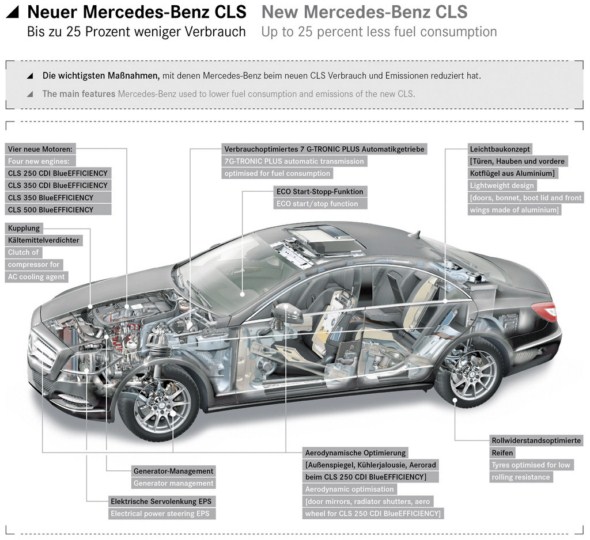

- More efficiency: up to 25 percent lower fuel consumption

- More agility: lightweight construction and new electromechanical power steering

- More visibility: LED High Performance headlamps

- More safety: Active Blind Spot Assist and Active Lane Keeping Assist

A generation ahead: with the CLS, Mercedes-Benz created a new vehicle category in 2003 which for the first time combined the elegance and dynamism of a coupé with the comfort and functionality of a saloon.

The customers were delighted, the competition taken aback: for many years the CLS remained the only four-door coupé in its class and since October 2004 it has been the car of choice for some 170,000 buyers around the globe.

“Customers all over the world have rewarded us for our courage in launching a completely new vehicle concept onto the market,” explains a delighted Dr Joachim Schmidt, Head of Sales & Marketing for Mercedes-Benz.

“And with its exciting design and refined sportiness, the new edition of the CLS also benefits from the fact that we are a whole generation ahead of the competition with our four-door Coupé.”

The engines: higher output, yet up to 25 percent lower fuel consumption

Efficiency at the highest level: that is what characterises all four engines deployed in the Mercedes-Benz CLS. The output and torque of each engine is greater than in its predecessor; at the same time, fuel consumption has been drastically reduced, by up to 25 percent.

Two 6-cylinder models will be available at first at the European market launch in January 2011: the CLS 350 CDI BlueEFFICIENCY with 195 kW (265 hp) and the CLS 350 BlueEFFICIENCY with 225 kW (306 hp) and the ECO start/stop function as standard.

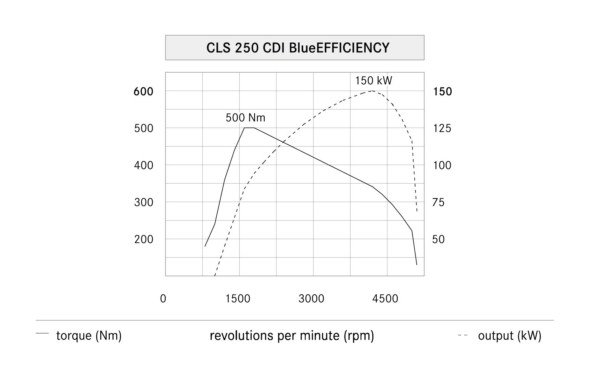

Just two months later, the engine range will be expanded to include the CLS 250 CDI BlueEFFICIENCY with 150 kW (204 hp). In the ECE fuel consumption test cycle it requires a mere 5.1 litres of diesel/100 km.

The CLS 500 BlueEFFICIENCY, with a V8 engine and 300 kW (408 hp), will follow in April. Both drive variants also have the ECO start/stop function as standard.

Lightweight construction and aerodynamics: important contributions to efficiency

Intelligent lightweight construction plays a decisive role in bridging the classic conflict of objectives between low weight and high strength in the new CLS. The CLS is thus the first vehicle from Mercedes-Benz to have frameless, all-aluminium doors.

These are made from deep-drawn aluminium panels with extruded sections, and in comparison with conventional steel doors, are some 24 kilograms lighter.

Apart from the doors, the bonnet, front wings, boot lid, parcel shelf, various support profiles and substantial parts of the suspension and engines are all made of aluminium.

Aerodynamics play an important part in the outstanding efficiency of the Mercedes-Benz CLS. Although the new model is wider than its predecessor and thus presents more frontal area to the wind, it was possible to reduce wind resistance by up to ten percent. This is thanks to the Cd value of 0.26, which has been improved by 13 percent.

Electromechanical power steering: a new steering experience

Marrying the ultimate in driving dynamics to the very best in long-distance ride comfort, was the challenge set for the designers and developers of the suspension system for the new Coupé, which aspires to be the epitome of stylish sportiness in both form and function.

To achieve this, the suspension system, which had already attracted the highest praise from both the trade press and the public when introduced with the new E-Class, was completely re-tuned and enhanced with a key new component: the electromechanical power steering system makes its world debut in the new CLS.

This pioneering innovation makes a new and radical contribution to the relationship between driver, car and road: engineers have, for the first time, been given the freedom to select and to program many of the parameters which influence the steering feel.

In addition, the steering system makes an important contribution to the CLS’ overall efficiency: as the steering support system only uses energy when the vehicle is actually being steered, fuel consumption is cut by up to 0.3 litres/7 g of CO2 compared to the previous model.

For the front suspension, the concept of a three-link front axle design was chosen – just as for the E-Class – and was especially developed for the new CLS.

The principle of a lightweight-construction multi-link rear suspension which is attached to a subframe, as used in the new E-Class, was adopted for the CLS as a result of its unsurpassed wheel location qualities.

In comparison to its predecessor, all the components have been modified to give both greater comfort and better driving dynamics.

LED High Performance headlamps: greater visibility and full functionality

The CLS is the first passenger car in the world to offer LED High Performance headlamps, which combine the exciting colour elements of LED technology – similar to those of daytime running lamps – with the performance, functionality and energy efficiency of today’s bi-xenon generation (as an optional extra).

This new light system provides, for the first time ever, the Intelligent Light System already proven in Mercedes models fitted with bi-xenon headlamps in combination with LED technology.

The headlamps, with their 71 LED lamps in total, look exciting; and they serve to underline the unmistakable appearance of the CLS.

The light specialists from Mercedes-Benz have for the first time been able to use LED technology in the admired and innovative Adaptive Highbeam Assist, resulting in an entirely new level of safety for night-time driving.

In contrast to the first vehicles equipped with LED headlamps, no compromises are now necessary with respect to the functionality and performance of the lighting technology.

There are further arguments for the LED-based lighting technology: the average operating life of an LED is around 10,000 hours, around five times longer than that of a xenon light; moreover, LED headlamps most closely approximate to the colour of daylight.

This means that LED light is in keeping with the normal human perception patterns and that the driver experiences significantly more brightness on the road at night.

Studies have shown that the closer the colour of artificial light comes to daylight, the less the strain on the eyes. With a colour temperature of 5500 kelvin, LED light is closer to daylight (6500 K) than xenon light (4200 K).

New driving assistance systems: greater safety

More than a dozen driving assistance systems on the new CLS help to prevent traffic accidents and reduce the severity of an accident. The Active Blind Spot Assist and the Active Lane Keeping Assist are new.

Active Blind Spot Assist warns the driver if – with the assistance of short-range radar sensors – it detects that there is a danger of collision if the vehicle is about to change lanes.

Should the driver ignore the warnings and the vehicle come dangerously close to the next lane, Active Blind Spot Assist will intervene.

By applying braking force to the wheels on the opposite side of the vehicle via the Electronic Stability Program ESP®, a yaw movement is created which counteracts the collision course.

Active Lane Keeping Assist is now also linked to ESP® for the first time. This system kicks into action if the Mercedes vehicle inadvertently drifts over a solid line to the right or left of a lane.

In this case, Active Lane Keeping Assist uses the ESP® to gently brake the wheels on the far side and thereby bring the vehicle back on course.

A display on the instrument cluster warns the driver at the same time. If broken lane markings are crossed, the system controls an electric pulse generator in the steering wheel which generates vibrations for a short time – a discreet but highly effective cue to countersteer immediately.

Before the braking system intervenes, the steering wheel always vibrates to provide a warning.

The exterior: classic Coupé styling with distinctive front

The new CLS continues with the pioneering role of its predecessor and at the same time shows itself to be a brand-new star on the scene.

What immediately strikes the eye is the innovative front design, which is reminiscent of the Mercedes-Benz SLS AMG. Visually, the radiator grille is not integrated into the bonnet but is formed separately.

This highlights the long, sporty bonnet even further. The grille is dominated by the large central star, which underlines the car’s relationship to the other coupés of the brand and strengthens the brand identity.

The typical CLS outline, with its elegantly long proportions, is the dominating attribute of the new model. The effect of the dynamic, athletic form has been enhanced with a new interplay of lines and areas.

The front edge of the structure above the wings slopes off towards the rear.

This novel design feature, called the dropping line by designers, represents a new interpretation of a formal design element harking back to the uniquely rich wealth of forms present in historic Mercedes sports cars.

A distinctive and muscular sports car-like shoulder line above the rear axle highlights the athletic character of the new CLS. The flared wheel arches resemble the powerful thighs of a feline predator waiting to pounce.

The interior: design brings quality to life

The interior of the CLS is also distinguished by a timeless design which combines straightforward elegance with innovative details and handcrafted perfection.

An eye-catching feature is the wrap-around effect of the cockpit: a high line sweeps from the driver’s door over the instrument panel support and across to the front passenger door.

The central display has also been integrated harmoniously into the upper part of the instrument panel. At the same time, the downward sweeping side line on the doors continues the dynamic dropping line of the exterior.

As a design trendsetter, the CLS sets new standards in interiors with its wide variety of individualisation options. Five interior colours, five trim designs and also three qualities of leather are available to choose from.

The CLS lives up to its role as a design icon through the innovative material finishes used. An example of this is the exciting interplay of satin-finish and shiny metallic surfaces.

The CLS also exudes refined sportiness with its lavish and high-class trim elements which can be found on the instrument panel support, the centre console and parts of the door trim.

The customers can choose between three exclusive wood types: high-gloss brown burr walnut, high-gloss black ash and satin-finish light-brown poplar.

The interior is given an even more progressive look with the addition of piano lacquer or AMG carbon fibre trim elements.

- Distinctive: the elegant coupé outline combined with the expressive front

- Lavish: generous use of flawlessly crafted natural materials

Outrageous proportions: a long bonnet, narrow-look windows with frameless side windows, dynamic roof sweeping back at an angle towards the rear. In 2003 the four-door Coupé was born: and the Mercedes-Benz CLS immediately established itself as a new style icon.

The proportions have stayed the same – and yet everything is different: the second generation of this design trendsetter has adopted a completely new look.

What immediately strikes the eye is the innovative front design, which is reminiscent of the Mercedes-Benz SLS AMG. Visually, the radiator grille is not integrated into the bonnet but is formed separately. This highlights the long, sporty bonnet even further.

The grille is dominated by the large central star, which underlines the car’s relationship to the other coupés of the brand and strengthens the brand identity. The large, elongated dark air inlets with black grilles also add to the vehicle’s athletic appearance.

Another distinguishing feature comes in the form of the LED High Performance headlamps, which are the world’s first to offer all of the regular dynamic light functions using LED technology.

This innovation boasts an impressive design – inside it is divided into three arrow-shaped layers from top to bottom: the upper layer contains an LED indicator, beneath which is a striking LED side light offering LED low beam functions.

The side light can also be seen when the dipped beam function is switched on, thereby creating a novel and separate night-time design as a distinctive look.

The lowest level of the headlamp houses the main beam and nightview functions. A total of 71 LEDs not only provide an unmistakable appearance, but also offer a significantly enhanced view of the road compared with previous systems.

The typical CLS outline, with its elegantly long proportions, is the dominating attribute of the new model. The effect of the dynamic, athletic form has been enhanced with a new interplay of lines and areas. The front edge of the structure above the wings slopes off towards the rear.

This novel design feature, called the dropping line by designers, represents a new interpretation of a formal design element harking back to the uniquely rich wealth of forms present in historic Mercedes sports cars.

A distinctive and muscular sports car-like shoulder line above the rear axle highlights the athletic character of the new CLS. The flared wheel arches resemble the powerful thighs of a feline predator waiting to pounce.

The side view is rounded off with wide wrap-around tail lights featuring LED technology which are arranged in the form of a linking element to the rear of the vehicle.

The shape is emphasized by the broad shoulder line, which is clearly visible from behind and supports the flat hardtop. A wide metal insert adds a further visual highlight at the rear.

The interior: design brings quality to life

The interior of the CLS is also distinguished by a timeless design which combines straightforward elegance with innovative details and handcrafted perfection.

An eye-catching feature is the wrap-around effect of the cockpit: a high line sweeps from the driver’s door over the instrument panel support and across to the front passenger door.

The central display has also been integrated harmoniously into the upper part of the instrument panel. At the same time, the downward sweeping side line on the doors continues the dynamic dropping line of the exterior.

As a design trendsetter, the CLS sets new standards in interiors with its wide variety of individualisation options. Five interior colours, five trim designs and also three qualities of leather are available to choose from.

As a result, each CLS is a one-off piece and can be configured individually between warm naturalness and cool modernity.

The CLS also lives up to its role as a design icon thanks to the innovative nature of the materials used. These comprise an exciting mixture of satin and high-gloss finishes used on the metal surfaces.

Highlights here also include matt galvanised air vents, for example, which form the ideal framework for a high-gloss-trimmed analogue clock.

Handcrafted perfection is reflected in details such as the stitched seat covers or the so-called sewn covering for the dashboard. For the latter, the individual parts of the leather cover are sewn together by hand in a process which takes several hours, after which they are fitted and upholstered with high-quality foam.

Prior to this process, the leather is also heated up to preshrink it, so that it will retain its shape even after extreme exposure to direct sunlight.

The particularly fine, 1.6-millimetre thick semi-aniline PASSION leather which is used meets the highest standards in terms of both look and feel.

Protected by only a light pigmentation, the natural pore structure remains intact and the leather has an especially warm and soft feel to it.

Since the natural characteristics also remain visible for the most part, the semi-aniline leather requires a very precise manual selection process.

The refined sportiness of the interior of the CLS is further reflected in the generous use of high-quality trim elements. They are located on the instrument panel support of the centre console and on parts of the door linings.

Customers can choose between three exclusive types of wood: high-gloss brown burr walnut, high-gloss black ash and satin-finish light-brown poplar.

The wood has even been perfectly fitted around difficult contours for a masterful handcrafted finish, and the wood trim has been matched according to grain, as part of an elaborate selection process, to create a harmonised overall impression.

The interior is given an even more progressive look with the addition of piano lacquer or AMG carbon-fibre trim elements. Handcrafted perfection once again plays a prominent role in the production process.

Up to seven layers are applied and polished for the piano lacquer trim, for example, until the desired high-gloss finish is achieved.

The interior

Luxurious surrounds with many exclusive touches

- Roomy: more elbow and shoulder room for all the seats

- Informative: full-colour central display in the instrument cluster

Quite apart from its breathtaking design, the vehicle body of the new CLS spoils all occupants with its generous interior measurements: in particular, the four-door coupé offers more elbow room (8/21 millimetres at the front/back) and more shoulder room (21/13 millimetres) than its predecessor.

The starting point for this extra space was the vehicle body, which is 29 millimetres longer, 13 millimetres higher and 8 millimetres wider than its predecessor. The wheelbase has increased too, by 20 millimetres to 2874 millimetres.

The boot has a capacity of 520 litres and, for the first time in the CLS, comes with EASY-PACK quickfold as an optional extra for the rear seat backrest which folds down in a 1/3:2/3 proportion.

Up to 19 different places to store and secure objects throughout the car make it quick and easy to accommodate smaller objects.

The EASY-PACK comfort box for the boot, which is an optional extra, provides even more stowage space. It is normally folded flat and stored under the parcel shelf. If the EASY-PACK comfort box is needed, it can be pulled out and folded down.

Thanks to its flexible base, its volume can be varied from 7 to 55 litres. Its can bear a maximum of ten kilograms in weight. The box, which is some 530 millimetres wide, can be removed from the boot without the need for tools if its full capacity is required.

Stylish cockpit with three round dials and two colour displays

In addition to the “wrap-around effect” of the instrument panel support, the newly-designed multifunction steering wheel in the 3-spoke design in Nappa leather is particularly eye-catching.

The steering wheel is available in black or almond beige; a wood-and-leather finish is also available as an optional extra.

In the optional AMG Sports package there is a particularly sporty steering wheel which has a flattened wreath in the lower half. Both steering wheel options have 12 multifunction keys to control the infotainment functions.

The highlight of the exclusive CLS instrumentation is the all-colour, three-dimensional TFT display in the middle of the speedometer, measuring 109 millimetres in diameter.

The mileage and trip odometer appear in the lower area of the display, the top displays – amongst other things – information from the driver assistance systems.

A three-dimensional image of the vehicle appears when getting into or out of the CLS.

Three tube-shaped round dials in the cockpit inform the driver of the coolant temperature and fuel tank level (on the left), speed (in the middle) and engine rpm (on the right).

A large colour display in 16:9 format, elegantly integrated into the upper part of the instrument panel support, gives information on all the infotainment functions.

The TFT display (Active Matrix Thin Film Transistor), which is backlit with LED lights, uses so-called IPS technology. IPS stands for “in-plane switching”, which describes the shift direction of the liquid crystal.

The benefit of this technology is that it displays high-contrast images which stay sharp outside the direct line of vision.

Depending on the specification, two versions of this cutting-edge display are available: a 14.7 cm version for the Audio 20 and Audio 50 APS systems; and a high-resolution 17.7 cm variant for COMAND APS.

The centre console fits harmoniously with the shape and colour of the instrument panel. The control unit for the infotainment system and the optional car telephone can be found underneath the analogue clock and air vents.

The push-button switches for seat heating, seat ventilation, the hazard warning lamps, rear window blind and other items of equipment ordered as options are arranged below this; they have been galvanised and are backlit.

The large round control knobs for the automatic climate control, which is supplied as standard, are located in the lower part of the centre console.

The controller in the tunnel trim serves as the central control element for the infotainment systems and provides a quick and easy starting point for navigating the well-organised menus controlling the systems.

THERMOTRONIC climate control with three individual climate modes

The second-generation CLS can be optionally fitted with an automatic climate control system which not only allows individual temperatures to be set for three zones – for the driver, the front passenger and the rear passengers – but additionally offers special climate modes.

This means that, if the optionally available THERMOTRONIC system is fitted, the car occupants can select “Diffuse”, “Medium” or “Focus” settings on the THERMOTRONIC at the push of a button and thus adjust the air quantity and air distribution to their liking without having to leave the convenient automatic mode.

In “Diffuse” mode, for example, the THERMOTRONIC system operates with a lower air speed and distributes the air over a wide area so that there are fewer draughts.

This is the purpose of the automatically controlled, upwards inclined diffuse nozzle in the centre of the dashboard.

In “Focus” mode, meanwhile, the air outlets in the centre area of the dashboard are used for the most part, meeting the need for a direct flow of a larger quantity of air.

The standard system fitted in the CLS is the two-zone THERMATIC automatic climate control.

The ultimate in seating comfort allowing adjustments to suit individual ergonomic needs

Refined sportiness – this philosophy applies also to the seats, as they combine the ultimate in seating comfort with sporty lateral support. Four different front seat types are available to choose from:

- The standard seat itself meets the highest ergonomic standards. Thanks to the filled seat piping, the feeling of comfort simply when getting into the vehicle is unique. A special upholstery technology is deployed here, which inserts additional foam filling immediately beneath the cloth or leather upholstery. The front seats can be adjusted electrically as standard. The Memory package, which enables three individual settings to be saved, is available as an optional extra.

- The shape of the optional multicontour seat can be individually adjusted by and for the driver and passenger to fit their anatomy or to suit their personal wishes with regard to comfort. Thanks to an innovative technology for adjusting the seat side bolsters, for example, the width of the backrest can be adjusted on both sides in a stepless operation by up to 45 millimetres, i.e. by up to 90 millimetres in total. Other bonuses of the new multicontour seat include the pneumatic height adjustment facility for the seat cushion and the high-comfort head restraints.

- The active multicontour seat offers the same comfort functions and additionally has high-speed piezo valves in the air chambers which adjust the charging pressure and volume of the air chambers in the side bolsters of the seat backs, depending on the steering angle, lateral acceleration and vehicle speed, to provide both the driver and front seat passenger with even greater support. It also has the high-comfort head restraint and, additionally, a massage function.

- Climate comfort is further enhanced by the optionally available active climatised front seats, which are available as an optional extra. Four ventilators in the seat cushion and in the backrest extract cool air from the floor area of the interior and distribute it evenly through a ventilation tissue beneath the seat surface. The mild airflow can prevent the car’s occupants from sweating, even when it is extremely hot outside. Seat heating can also be selected for all four seats as an optional extra.

Individual seats for the passengers in the rear, for the first time fitted with ISOFIX child seat attachments

Two individual seats in the rear provide a particularly comfortable experience in the second row. These seats are well-liked for their extensive lateral support which comes from the contouring.

There is a roomy stowage compartment in the centre armrest between the two seats, which if desired can also contain a cup holder for a bottle.

An electrically-operated rear-window blind for the rear passengers is also available as an option, which can palpably and measurably reduce sunlight streaming in at the touch of a button. It is fixed to the C-pillars, as it is in the S-Class.

For the first time Mercedes-Benz is offering the CLS with ISOFIX, the international standard securing system for child seats. The mechanism is fitted as standard and comprises two retaining brackets in each rear seat position, in the gap between the back rest and seat cushion, as well as an additional third anchor point above the backrest, the so-called top tether.

Car radio, CD player and Bluetooth interface as standard

Nowadays, nobody wants to miss out on the news, the telephone, route guidance or music listening pleasure when in the car.

For this reason Mercedes-Benz has equipped the new CLS with state-of-the-art infotainment facilities, which stand out for their high performance capability, but above all for their ease of use.

They are called the Audio 20 CD (supplied as standard), Audio 50 APS and COMAND APS (supplied as optional extras).

All of the devices include speed-sensitive volume control, a keypad for entering telephone numbers and radio frequencies, a colour display in the centre of the dashboard, and a Bluetooth interface to connect a mobile phone to the hands-free system wirelessly.

Eight loudspeakers supplied as standard and located in the doors ensure excellent sound quality.

Features of the Audio 20 CD system, fitted as standard, include a CD player (with MP3 capability), a dual tuner for FM/MW/LW/SW, automatic station search, RDS function (FM reception) and a 4 x 20-watt amplifier.

The AUDIO 50 APS infotainment system is an all-in-one device featuring a combination of car radio, DVD player and Europe-wide navigation system with two-dimensional map display.

The radio functions and the options for linking with other systems are the same as for the Audio 20 system. Mercedes customers who opt for the version with integral six-disc DVD changer also receive the LINGUATRONIC voice-operated control system.

The COMAND APS multimedia system developed by Mercedes-Benz includes a DVD player for audio and video as well as a Europe-wide navigation system whose data are stored on a 40-gigabyte hard drive, allowing extremely fast access to the navigation data and, compared to DVD-based navigation, even faster route calculations.

The high-resolution map appears on the 17.7 cm colour display in the centre of the instrument panel and excels in providing useful additional information.

By way of example, the map shows the outlines of prominent buildings along the route to aid orientation.

Mercedes-Benz combines COMAND APS with the voice-operated control system LINGUATRONIC and a so-called text-to-speech function as standard.

This makes it possible for route-related traffic reports, SMS messages, address book entries or radio station names to be read out to the driver. The system automatically reads out new traffic reports that are relevant to the current route.

Additional systems for the ultimate in listening pleasure and entertainment

Mercedes customers can, if desired, combine the infotainment facilities for the CLS with other systems:

- The Logic7 surround sound system developed by Mercedes-Benz together with the audio specialists harman/kardon® delivers an outstanding performance with three-dimensional sound as a natural 360-degree musical experience for all passengers.

- iPods, USB sticks or other external audio devices can link to the infotainment system of the new CLS through a media interface in the stowage compartment in the centre console.

- A separate DAB tuner (DAB = Digital Audio Broadcasting) and additional aerials (optional) allow passengers on board the new CLS to receive digital radio stations in CD quality. The system switches to analogue reception automatically when the DAB signal is too weak.

The positioning

Ground-breaking products from the inventor of the four-door coupé

- Looking back: more than 170,000 models of the first CLS sold worldwide

- Looking forward: European market launch of the new CLS in January 2011

A generation ahead: with the CLS, Mercedes-Benz created a new vehicle category in 2003 which for the first time combined the elegance and dynamism of a coupé with the comfort and functionality of a saloon.

The customers were delighted, the competition taken aback: for many years the CLS remained the only four-door coupé in its class and since October 2004 it has been the car of choice for some 170,000 buyers worldwide.

A surprisingly large number of them were buying their first Mercedes-Benz at the time. “Customers all over the world have rewarded us for our courage in launching a completely new vehicle concept onto the market,” explains a delighted Dr Joachim Schmidt, Head of Sales & Marketing for Mercedes-Benz.

“And with its exciting design and refined sportiness, the new edition of the CLS also benefits from the fact that we are a whole generation ahead of the competition with our four-door Coupé.”

The first CLS, which first appeared as a study entitled “Vision CLS” at the IAA in 2003, was, as a design icon, a clear statement: 64 percent of European customers bought it on the grounds of its design. This was the clear result of the New Car Buyer Survey.

The fact that its shape and form has a timeless beauty is demonstrated not just by the countless design prizes won but also by winning the German industry magazine “Motor Klassik” readers’ award: in 2009 the CLS was voted “the Classic Car of the Future”.

With its out-of-the-ordinary design, the new CLS is following on in the footsteps of its predecessor and will appeal to car connoisseurs who appreciate sense and sensibility.

In addition to its special shape and form, and the perfect craftsmanship deployed, it also fulfils its technical role as an innovator: so it is that the new CLS is launched from the start with completely new engines.

In combination with further measures to increase efficiency such as the ECO start/stop function or the more advanced 7-G-TRONIC PLUS automatic transmission, this gives a saving in fuel consumption of up to 25 percent.

Further brand-new features include the Active Parking Assist and the LED High Performance headlamps, which for the first time offer all the dynamic light functions in LED technology (for more information on both, please see the section “Active Safety”).

Given the CLS customers’ traditional willingness to accept innovations, market researchers for Mercedes are already forecasting take-up rates for both innovations of over 80 percent.

Europe will be the largest market for the CLS: with an estimated share of sales of 46 percent, nearly every second CLS is expected to be delivered to the ECE states.

It will go on sale in January 2011. In North America, where only the two most powerful models will be sold, the market launch will take place four months later.

The model range

Every CLS is a one-off

- Customers can choose from 12 paint finishes, five interior colours and five trim finishes

- To mark the launch: the “Edition 1” special model with matt paint finish

Individuality is written large in the new Mercedes CLS. The model range for the four-door Coupé is correspondingly extensive – it will be at first be available with rear-wheel drive and then, from September 2011 onwards, for the first time as a 4MATIC with all-wheel drive.

As regards the drive system, customers will at first have a choice between four petrol and diesel engines, with four, six and eight cylinders and an output range of between 150 kW (204 hp) and 300 kW (408 hp), or 2143 to 4633 cc displacement.

A total of 12 different paint finishes, including the SHAPE manganite grey matt paintwork, can be combined with the five interior colours – black, alpaca grey, almond beige, aubergine and porcelain.

Three different versions of leather upholstery are available to choose from: leather (nappa leather), PASSION leather (a fine semi-aniline leather) and Exclusive PASSION leather (where also the instrument panel and beltline are leather-covered).

There are five different finishes available for the trim elements – brown high-gloss burr walnut, black high-gloss ash, satin-finish light brown poplar, black piano lacquer as well as AMG carbon fibre for the CLS Edition 1.

In this way, customers purchasing a CLS can, according to their own tastes, choose to accentuate either fresh naturalness or elegant sportiness.

Countless optional extras make it possible to individualise one’s CLS further – including opting for active multicontour seats, LED High Performance headlamps, Keyless Go and the harman/kardon sound system, as well as many support systems including the new Active Blind Spot Assist and Active Lane Keeping Assist with brake actuation (for more information on the latter, please refer to the section “Active Safety”).

Over and above this, Mercedes-Benz has put together three packages offering appropriate combinations of optional extras.

A customer opting for the Exterior Sports package will get a CLS with visible, chromed tailpipes. The Sport CLS also has a lowered suspension with sports tuning, alloy wheels in size 18 or 19 (and, optionally, in anthracite) and a trim element in black on the rear bumper.

The AMG Sports package comprises a multifunction sports steering wheel in nappa leather in the 3-spoke design, with flattened bottom section, aluminium pedals, AMG bumpers to the front (with single-louvred grille) and rear, AMG alloy wheels in size 18 or 19, AMG floor mats, visible tailpipes, and in the interior, in combination with black leather seats, light-coloured felled seams on the seats, headrests and armrests.

With the AMG Sports package, the automatic transmission has a third shift programme – M – which allows the gear to be selected manually using the paddles on the steering wheel. In addition to this, the adaptive suspension is more sportily tuned.

The Exclusive package combines seats in fine semi-aniline leather with nappa leather for the instrument panel, centre console and parts of the door trim. The roof lining is made of alcantara.

The Exclusive package, which also includes ambient lighting, is available with all the interior colours and trim elements.

The CLS “Edition 1” will be available for a limited period of one year following market launch. The distinguishing features of this special model are the SHAPE matt paint finish in manganite grey; the leather upholstery in designo corteccia tundra brown pearl which has a metallic shimmer to it; floormats with Edition 1 lettering; a black roof liner; and aluminium pedals.

For the interior trim elements in the Edition 1 there is a choice between satin-finish light brown poplar, black piano lacquer or AMG carbon fibre.

The bodywork

A first: frameless, all-aluminium doors

- Made to be light: aluminium and high-strength steel alloys

- Made to be safe: stable bodywork structure and a high degree of rigidity

Intelligent lightweight construction plays a decisive role in bridging the classic conflict of objectives between low weight and high strength in the new CLS.

The CLS is thus the first vehicle from Mercedes-Benz to have frameless, all-aluminium doors. These are made from deep-drawn aluminium panels with extruded sections, and in comparison with conventional steel doors, are some 24 kilograms lighter.

This is not only beneficial to the environment, operating convenience is increased too: the Coupé doors can be opened and closed more easily, particularly on an incline.

The new construction has called for new joining techniques instead of welding, a combination of gluing and riveting has been used.

In order to assure quality, in the production process the doors are positioned in the frames by extremely precise robots; and the side windows are fitted with the greatest precision using laser measurement technology.

As a result, this door design meets the same seal requirements as for the door frames on a saloon, which has to be demonstrated in a Mercedes internal test (one of several) in which it is subjected to high-pressure testing with water pressure at 80 bar.

To put this in context: this pressure is about five times higher than the pressure needed by an espresso machine to produce a good crema.

Apart from the doors, the bonnet, front wings, boot lid, parcel shelf, various support profiles and substantial parts of the suspension and engines are all made of aluminium.

The front end is a hybrid construction made of aluminium panels and plastic strengthened with fibre-glass. The one-piece aluminium crash boxes in the front area are fitted in the side members and are screwed into the side with them.

The large front bumper with the integral grille with the centred star is made of polypropylene. The materials experts at Mercedes-Benz have worked together with the experts from the supplier of this part to develop the plastics formulation, which has a specific talcum content of 15 percent, in order to achieve an optimum compromise between weight and rigidity, as well as excellent thermal properties.

As supporting structure for the bumper there is a front end which is a hybrid construction of aluminium sheet and plastic strengthened with fibre glass. For every CLS, special adjustable fixtures are used to ensure the front fits exactly and the gap dimensions are the same all round.

About 72 percent of all panels used for the bodyshell of the new CLS are made from rigid and ultra-rigid steel alloys. The ultra-rigid high-tech alloys, which have three to four times more tensile strength than conventional rigid types of steel, account for around eight percent of total weight.

They are deployed in areas in which there could be extreme material stresses in the event of an accident – for example, in the event of a side-on collision, in the B-pillars and side frame of the roof; as well as in the rear, to create a stable crossmember.

Front-end structure: crumple zone on four levels

Compared to the previous model series, the Mercedes engineers have further enlarged the deformation zones substantially in the front and rear sections of the new CLS, as well as improving the energy flows.

The front crumple zone has four independently acting impact levels, meaning that the forces can be distributed over a wide area while bypassing the passenger cell.

- Sectional panels above the wheel arches form the upper side-member level. From here, the impact forces are channelled into the A-pillars and, subsequently, into the roof frame.

- An aluminium crossmember connects the forward-extended side members and ensures that the forces are transferred to the side facing away from the impact. The crossmember and the forward-extended side members form the central impact zone.

- The subframeto which the engine, steering and front axle are attached also serves as an impact level in the event of a frontal collision. It is made of high-strength steel and, depending on the engine variant, can be connected to the newly developed floor side members by means of special supporting tubes. As a consequence, the subframe can deform in a predetermined manner and absorb energy in the event of a crash on the one hand and channel high impact forces straight into the vehicle floor on the other.

- The side skirts have been extended forwards to support the wheel and prevent it from entering the footwell in the event of an offset frontal collision. In order to provide specifically targeted front-wheel support and location, Mercedes-Benz has also developed special struts and additional energy-absorbing elements for the wheel arches. The struts are arranged diagonally and prevent the passenger cell from sinking in the event of an impact.

The firewall is a four-part construction. This design enables Mercedes engineers to vary the material thickness according to the level of vulnerability in an accident.

As the load acting on the firewall during a frontal crash is greatest in the lower section, the sheet steel used here is almost 50 percent thicker.

As well as being a major reason behind the high level of impact resistance, this intelligently designed bodyshell not only enhances ride comfort, it also reduces noise and vibration.

The Sindelfingen engineers paid particular attention to the connecting points between the suspension and the bodyshell, which are required to withstand very high forces.

These were specifically reinforced to ensure that road-induced vibrations are not transferred to the body at the expense of driving enjoyment.

An indicator of the excellent overall result is the static flexural strength of the bodyshell, which shows a 28 percent improvement over its predecessor. Torsional strength increased by six percent.

Passenger cell: custom-designed floor panels and robust load-bearing sections

The passenger cell of the new CLS has been shown to be a structure which is virtually immune to deformation and which keeps the occupant space intact, even at high impact speeds, regardless of whether the collision is head-on, from the rear or from the side, or whether the vehicle rolls over.

The use of high-strength steel and thicker panels plays as important a role here as the installation of additional load-bearing members.

The main floor assembly thus consists of different sheet-metal plates that either undergo flexible rolling or are welded together by laser beam and subsequently shaped.

Flexible means that the high-tensile steel can be processed in such a way that areas with different steel thicknesses can be produced within a single component.

The middle blank forms the tunnel – the actual backbone of the passenger cell. Here the thickness of the custom-designed panels varies between 0.7 and 1.1 millimetres, and between 1.55 and 2.0 millimetres for the tunnel reinforcements, depending on the stresses and loads to which they are subjected.

The continuous floor side members, the insides of which are further reinforced with extra sections, are very important both for occupant protection and the rigidity of the bodyshell.

Their front faces connect to the side members, thereby lengthening the load-bearing paths along which forces can be distributed in the event of an impact.

At the rear, the floor side members extend as far as the crossmember beneath the rear seat unit to stabilise the entire floor structure.

The Mercedes engineers have also incorporated sturdy aluminium transverse sections – known as transmission tunnel braces – into the floor assembly.

One is located beneath the transmission, and is designed to direct forces to the side of the vehicle facing away from the impact in the event of a side-on collision.

The second forms a connection between the two side members. It likewise braces the floor assembly and is able to channel impact forces into the floor structure at an early stage following a side-on collision.

Rear-end structure: side members with specifically graduated material thicknesses

Multi-piece side members and a robust, flexible crossmember made from ultra-high-strength steel form the key components of the rear-end structure.

The rear side members are continuous, closed box sections with carefully graduated material thicknesses. These are able to absorb high forces, thereby making a decisive contribution to occupant safety in the event of a rear impact.

The bolt-on flexible crossmember is manufactured using a flexible rolling process which likewise allows the material thickness to be varied as required.

Accordingly, the material thickness on the outside of the crossmember – where impact loads are highest – is greater than on the inside.

Less drag and substantially quieter

Aerodynamics are a key contributory factor to the outstanding efficiency of the new Mercedes-Benz CLS. Although the new model is wider than its predecessor and thus offers the wind a larger frontal area, drag has been reduced by up to ten percent.

As a result of fine-tuning measures on the body and the application of technical measures such as a cooling air louver and aerodynamically optimised wheels, the Cd value – which defines the drag coefficient – has been reduced by 13%, to 0.26.

Other focuses of aerodynamic development have been on reducing wind noise and keeping all surfaces which contribute to visibility free of soiling – a key element of perceptual safety.

Specifically, the key focuses of aerodynamic development work were as follows:

- New exterior mirrors, optimised in terms of aerodynamics, aeroacoustics and dirt deflection, positioned expediently on the beltline

- Aerodynamically efficient design of the front and rear aprons and the boot lid

- Improved sealing of the radiator section and utilisation of air flows to make efficient use of the available cooling air, deployment of a cooling air louver

- Flow-optimised drip rails in the area of the A-pillars

- Optimum coordination between the taper of the C-pillars and the shaping of the vehicle’s rear end

- Aerodynamically optimised underbody with wheel spoilers and extensive engine compartment and main floor panelling

- Aerodynamically optimised wheels; Aero Wheel used for the first time on the CLS 250 CDI BlueEFFICIENCY

- When the CLS is fitted with AIRMATIC air suspension, the body is lowered by 15 millimetres at speeds of over 140 km/h

Wind noise: a highly refined driving experience even at high speeds

In order to improve comfort and in the interests of a more refined driving experience at high speeds in particular, the aerodynamics and body experts have tweaked a number of details to attain a further reduction in the noise level in comparison to the predecessor model.

The following measures result in reduced wind noise:

- Optimised sealing of joints between bonnet and radiator grille

- Positioning of the exterior mirror on the beltline, optimised joint sealing between head and base of mirror

- Elaborately designed wind deflector for the tilting/sliding sunroof

- Sophisticated system of seals between the frameless doors and the body; improved sealing of door handles; increased rigidity of the doors themselves

- Damping package at many points of the body to reduce low-frequency noise

Protection from soiling: further improvement in vision and visibility

The areas of the side and rear windows of relevance to safety remain free of soiling when driving in rain at between 80 and 160 km/h, thanks to effective channelling and drainage of the incoming water.

A water runnel with continuously diminishing height and an optimised roof trim strip channel water which lands on the front windscreen along the roof.

The mirror positioned on the beltline additionally helps to keep the side window free of soiling more effectively than a traditional bridge mirror.

The water flowing over the roof is diverted away from the rear window by means of a coordinated water management system comprising channels to the left and right of the rear window through which the water flows down.

Less drag and substantially quieter

Aerodynamics are a key contributory factor to the outstanding efficiency of the new Mercedes-Benz CLS. Although the new model is wider than its predecessor and thus offers the wind a larger frontal area, drag has been reduced by up to ten percent.

As a result of fine-tuning measures on the body and the application of technical measures such as a cooling air louver and aerodynamically optimised wheels, the Cd value – which defines the drag coefficient – has been reduced by 13%, to 0.26.

Other focuses of aerodynamic development have been on reducing wind noise and keeping all surfaces which contribute to visibility free of soiling – a key element of perceptual safety.

Specifically, the key focuses of aerodynamic development work were as follows:

- New exterior mirrors, optimised in terms of aerodynamics, aeroacoustics and dirt deflection, positioned expediently on the beltline

- Aerodynamically efficient design of the front and rear aprons and the boot lid

- Improved sealing of the radiator section and utilisation of air flows to make efficient use of the available cooling air, deployment of a cooling air louver

- Flow-optimised drip rails in the area of the A-pillars

- Optimum coordination between the taper of the C-pillars and the shaping of the vehicle’s rear end

- Aerodynamically optimised underbody with wheel spoilers and extensive engine compartment and main floor panelling

- Aerodynamically optimised wheels; Aero Wheel used for the first time on the CLS 250 CDI BlueEFFICIENCY

- When the CLS is fitted with AIRMATIC air suspension, the body is lowered by 15 millimetres at speeds of over 140 km/h

Wind noise: a highly refined driving experience even at high speeds

In order to improve comfort and in the interests of a more refined driving experience at high speeds in particular, the aerodynamics and body experts have tweaked a number of details to attain a further reduction in the noise level in comparison to the predecessor model.

The following measures result in reduced wind noise:

- Optimised sealing of joints between bonnet and radiator grille

- Positioning of the exterior mirror on the beltline, optimised joint sealing between head and base of mirror

- Elaborately designed wind deflector for the tilting/sliding sunroof

- Sophisticated system of seals between the frameless doors and the body; improved sealing of door handles; increased rigidity of the doors themselves

- Damping package at many points of the body to reduce low-frequency noise

Protection from soiling: further improvement in vision and visibility

The areas of the side and rear windows of relevance to safety remain free of soiling when driving in rain at between 80 and 160 km/h, thanks to effective channelling and drainage of the incoming water.

A water runnel with continuously diminishing height and an optimised roof trim strip channel water which lands on the front windscreen along the roof.

The mirror positioned on the beltline additionally helps to keep the side window free of soiling more effectively than a traditional bridge mirror.

The water flowing over the roof is diverted away from the rear window by means of a coordinated water management system comprising channels to the left and right of the rear window through which the water flows down.

Under the microscope: new assist systems for active safety

Protection against the blind spot, help when changing lanes

Active Blind Spot Assist warns the driver if it detects a risk of collision when changing lanes. Short-range radar sensors housed on both sides of the rear bumper monitor the areas directly alongside and behind the car.

This process enables them to see if there is another vehicle in the next lane – in the so-called blind spot. In such situations, the system informs the driver by illuminating a red warning signal in the glass of the exterior mirror.

If the driver fails to see this warning and indicates to change lanes, a warning signal sounds as well.

In an innovation from the latest stage of development, if the driver ignores warnings and the vehicle comes dangerously close to the next lane, Active Blind Spot Assist will intervene.

Applying braking force to the wheels on the opposite side of the vehicle via the Electronic Stability Program ESP® creates a yaw movement which counteracts the collision course.

The system intuitively deactivates as soon as the driver steers against the effects of the braking intervention or the vehicle accelerates.

If an accident can no longer be avoided in spite of correcting the direction, Active Blind Spot Assist can mitigate the consequences of a collision through course correction.

Where the system detects vehicles or obstacles just a short distance away on the opposite side, it will adapt its braking intervention accordingly. To do so, Active Blind Spot Assist also uses data from the front sensors for DISTRONIC PLUS proximity control.

Brake actuation to correct the course occurs between 30 and 200 km/h. The effect is limited to longitudinal and latitudinal deceleration of 2 m/s2.

When ESP® is in OFF mode, Active Blind Spot Assist is switched off. Visible warning in the exterior mirror is active up to a speed of 250 km/h.

Active Lane Keeping Assist with ESP® support

Active Lane Keeping Assist is now also linked to the ESP® for the first time. This system kicks into action if the Mercedes vehicle inadvertently drifts over a solid line to the right or left of a lane.

In this case, Active Lane Keeping Assist uses the ESP® to brake the wheels on the far side in order to prevent the vehicle from crossing the line and to bring the vehicle back on course.

A display on the instrument cluster warns the driver at the same time. If broken lane markings are crossed, the system controls an electric pulse generator in the steering wheel which generates vibrations for a short time – a discreet but highly effective cue to countersteer immediately.

Before the braking system intervenes, the steering wheel always vibrates to provide a haptic warning.

Active Lane Keeping Assist is based around a camera on the inside of the windscreen. It is able to recognise lane markings by analysing the difference in contrast between the road surface and the boundary lines.

The image processing solution informs an electronic control unit which determines and detects the position of the vehicle if it drifts out of this lane to the left or right.

For maximum reliability, the new generation of Lane Keeping Assist also evaluates radar signals in addition to image processing.

Only when both lane algorithms concur is braking force applied to correct the course. Unlike conventional systems of this type, the Mercedes assistance system also assesses the behaviour of the driver and is therefore able to determine whether the vehicle is leaving the registered lane intentionally or unintentionally.

Braking intervention to correct the course occurs between 60 and 200 km/h.

It does not materialise if:

- ESP® is deactivated,

- the radius of the bend is less than 150 metres,

- the vehicle is driving on tyres in emergency run-flat mode,

- when braking or accelerating by more than 2 m/s², on bends with lateral acceleration of over 2 m/s² (sporty driving style).

The steering wheel will not vibrate if the driver:

- is accelerating before overtaking or joining the motorway,

- brakes sharply,

- steers into a bend,

- cuts a corner intentionally,

- uses the indicators,

- is moving back into the original lane after overtaking,

- actively countersteers.

Furthermore, Lane Keeping Assist is deactivated immediately if ABS, ESP®, Brake Assist or another active safety system intervenes.

Passive safety

Nine airbags as standard

- New: pelvisbags and adaptive belt force limiters in the rear

- Available for the first time in the CLS: ISOFIX child seat securing system

- Enhanced further: PRE-SAFE occupant protection

Drivers of Mercedes vehicles are safer on the road than drivers of other car brands. This is the result of a study by Mercedes-Benz accident research based on official, anonymous data samples from the Federal Office of Statistics.

Having looked at 18,748 accidents resulting in personal injury during the period from 2003 to 2007, the study found that the risk of being seriously or fatally injured as the driver of a Mercedes is 9.6 percent lower than for vehicles of other brands.

The result represents clear evidence of the contribution made by the passive safety systems of Mercedes-Benz to reducing the consequences of an accident.

The main prerequisites for this include a stable body structure (see the section entitled “The Bodywork”) as well as a whole host of sophisticated restraint systems.

With nine airbags fitted as standard, not to mention four seat-belt tensioners and belt-force limiters as well as NECK-PRO crash-responsive head restraints for the driver and front passenger, the new CLS offers an even more extensive package of safety equipment than the previous model.

The airbags, which can deploy in a matter of milliseconds in the event of an accident, include two adaptive airbags for the driver and front passenger, a kneebag for the driver, two sidebags in the front-seat backrests and two large windowbags which extend from the A-pillar to the C-pillar during a side impact.

For the first time, pelvisbags are included as standard for front seat passengers, which in the event of a side collision can help to reduce loads in the pelvic area.

Sidebags are also available for the rear as an optional extra, which means that the new CLS makes a total of eleven airbags available for occupant protection.

Three-point automatic safety belts with belt tensioners and belt force limiters are fitted as standard for the driver, front passenger and rear passengers.

Mercedes-Benz is offering adaptive belt force limiters for the rear seats as an option. These adapt to the size of passengers automatically.

The system detects whether the rear seat passenger is large or small as soon as the seat belt is put on, based on the length of the pulled-out seat belt, and can adapt its protective effect accordingly.

The maximum belt force is activated immediately if the rear passenger is large in size, while in the case of smaller occupants the force exerted by the belt is initially set to a lower level.

For the first time Mercedes-Benz is offering the CLS with ISOFIX, the international standard securing system for child seats.

The mechanism is fitted as standard and comprises two retaining brackets in each rear seat position, in the gap between the back rest and seat cushion, as well as an additional third anchor point, the so-called top tether.

NECK-PRO is the name Mercedes-Benz has given to a crash-responsive head restraint whose development, like that of PRE-SAFE® and other Mercedes-Benz innovations, is based on analyses of real accidents.

NECK-PRO is an effective means of reducing the risk of whiplash injuries during a rear-end collision.

If the sensor system detects a rear-end collision with a defined impact severity, it releases pre-tensioned springs inside the head restraints, causing the head restraints to move forward by about 40 millimetres and upwards by 30 millimetres within a matter of milliseconds.

This means that the heads of the driver and front passenger can be supported at an early stage.

The occupant protection system PRE-SAFE®: preventive measures reduce the consequences of an accident by up to 40 percent

In 2002 Mercedes-Benz became the first automotive brand to offer an anticipatory occupant protection system which can initiate measures to protect the occupants of the vehicle if there is an imminent risk of an accident: PRE-SAFE®.

Mercedes-Benz’s intelligent approach takes its lead from nature: PRE-SAFE® activates protective measures for the car occupants as a precaution, just as living things react instinctively and search for cover when they are in danger.

The aim is to prepare the occupants and vehicle for an imminent collision so that the seat belts and airbags are able to fulfil their protective function to the full during an impact.

What’s more, the PRE-SAFE® protective measures are reversible: if the accident is averted, the advance tensioning of the seat belts is halted automatically and the occupants are able to reset the positions of the seats and the sliding sunroof. The anticipatory occupant protection system is then ready for action again straightaway.

Early accident detection is possible because PRE-SAFE® is an intelligent synergy of active and passive safety. It is linked to Brake Assist and the Electronic Stability Program (ESP®), whose sensors detect potentially critical driving situations and send the relevant information to the electronic control units within a matter of milliseconds.

The new CLS is able to offer even more preventive measures ahead of an imminent accident than ever before:

- Whereas PRE-SAFE® previously responded to emergency or panic braking – in other words when the driver hit the brake pedal reflexively – the system in the new CLS can also be activated if the optional DISTRONIC PLUS has detected an impending collision with the aid of short and long-range sensors, and a certain level of delay in braking has been exceeded. The occupants are prepared for the collision by tensioning of the seat belts and repositioning of the front-passenger seat (if the seat memory function is installed) – which is also optionally available with fully electric seat adjustment – enabling the seat belts and airbags to offer the best possible protection.

- The active multicontour seat (optional extra), ensures that the driver and front passenger are seated even more securely, thereby limiting dangerous whiplash movements by the upper body in the event of an accident. If the PRE-SAFE® control unit detects a critical driving situation, it immediately activates the air chambers in the seat cushions and backrests. These then envelope the seat occupants and give them support.

- Tests at the Mercedes-Benz Technology Center have shown that this PRE-SAFE® function and preventive belt tensioning increases the distance between the shoulder and the inner door lining by up to 40 millimetres at a lateral acceleration of 0.6 g. This enables the sidebag to fulfil its protective function even more effectively.

PRE-SAFE® triggers the following anticipatory measures:

| PRE-SAFE® when braking in an emergency | PRE-SAFE® if high lateral acceleration is detected ** |

| Driver and front-passenger seat belts are tensioned | The side windows can be closed |

| The seat fore-and-aft adjustment, and the cushion and backrest angles on the front passenger seat* are moved to the best possible positions for crash conditions | The sliding sunroof* can be closed |

| Bolsters in the seat cushions and backrests of the multicontour front seats* can be inflated |

*if fitted in the particular vehicle **in addition to the emergency-braking measures

When installed in combination with DISTRONIC PLUS, PRE-SAFE® also uses the information provided by the short-range radar sensors in the front bumper to tension the front seat belts at the very last moment before an unavoidable collision, thus reducing the forces exerted on the driver and front passenger during the crash.

This PRE-SAFE® function is literally the “ultima ratio” of anticipatory occupant protection, since the accident occurs around 200 milliseconds later.

The drive system

Four new engines giving the ultimate in driving pleasure

- Diesel engines: four-cylinder CDI available for the first time; V6 CDI is 21% more economical

- Petrol engines: BlueDIRECT reduces consumption by 25% in the V6

- Refined: ECO start/stop function for reduced consumption in urban traffic

- Now as standard: all engines come with enhanced 7G-TRONIC PLUS automatic transmission

Efficiency at the highest level: this is the common characteristic shared by all four engines used in the Mercedes-Benz CLS. All of the engines feature increased performance and torque compared with previous models, while at the same time boasting significantly reduced consumption and CO2 emission levels.

The two V6 engines are typical examples: the diesel engine in the CLS 350 CDI BlueEFFICIENCY now offers an increase in output of 30 kW, yet at an average of 6.0 litres/100 km consumes 21 percent less fuel than its predecessor.

Thanks to third-generation BlueDIRECT injection technology, the V6 petrol engine in the CLS 350 BlueEFFICIENCY is 25 percent more economical than before, despite an increase in maximum output of 10 kW: it now consumes just 6.8 litres per 100 km and matches its diesel counterparts in terms of CO2 emissions at 159 g/100 km, making them the global role models in their performance class.

Advances in efficiency which are every bit as impressive are also to be expected of the V8 engines. The CLS 500 BlueEFFICIENCY will become available during the course of the coming year. The CLS will also become available then with 4MATIC all-wheel drive for the first time.

Setting entirely new standards for efficiency in the luxury segment is the CLS 250 CDI BlueEFFICIENCY. Available for the first time in the four-door Coupé, the four-cylinder direct injection diesel engine has already enthralled customers of the E-Class.

With an output of 150 kW (204 hp), a top speed of 242 km/h and a full 500 Nm of torque, it provides complete driving pleasure yet will astound you when filling up with its consumption figures comparable to those of a compact car: on average the CLS 250 CDI BlueEFFICIENCY uses 5.1 litres per 100 km, which is equal to CO2 emissions of 134 g/km

In addition to optimisations in the powertrain – all CLS models are fitted with the enhanced 7G-TRONIC PLUS automatic transmission as standard – the sophisticated ECO start/stop system helps to ensure extreme efficiency even when driving in urban traffic. Like the petrol models in the CLS range, the CLS 250 CDI BlueEFFICIENCY is fitted with this system as standard.

The ultimate diesel: the V6 engine in the CLS 350 CDI

195 kW (265 hp) and 620 Nm of torque: the excellent diesel engine in the CLS 350 CDI BlueEFFICIENCY is now even more powerful and boasts a correspondingly superior performance.

The Coupé accelerates to 100 km/h in 6.2 seconds, and has a top speed of 250 km/h. And despite the increase in output of 30 kW and the additional tractive power of 80 Nm, the V6 consumes a fifth less fuel than previously, at 6.0 litres per 100 km.

To achieve this, the Mercedes engineers have basically revised the engine. It now has improved engine management in the form of new-generation control units and new software, new sensors and actuators, and more efficient aftertreatment in the maintenance-free diesel particulate filter system with reduced back-pressure.

In addition to more effective cooling of recirculated exhaust gas using a variable bypass valve, the in-engine measures include a reduction of the compression ratio from 17.7:1 to 15.5:1, an optimised VNT turbocharger with low-friction shaft bearings for greater agility and high output, new injection nozzles and revised ducting in the intake tract.

A whole package of measures has resulted in substantial fuel savings: these include generally lower in-engine friction (through precision honing of the cylinder walls, amongst other measures), more efficient thermal management, an improved compound oil pump and modified cylinder head cooling.

With an engine idling speed of 520 rpm, a new optimum value has also been achieved.

The diesel engines of the new CLS at a glance

| Model | CLS 250 CDI BlueEFFICIENCY | CLS 350 CDI BlueEFFICIENCY | |

| Cylinder arrangement / number | 4/in-line | V6 | |

| Displacement | [cc] | 2143 | 2987 |

| Rated output | [kW/hp] at [rpm] | 150/204 4200 | 195/265 3800 |

| Rated torque | [Nm] at [rpm] | 500 1600 – 1800 | 620 1600 – 2400 |

| Fuel consumption combined | [l/100 km] | 5.1 | 6.0 |

| CO2 emissions combined | [g/km] | 134 | 159 |

Petrol engine with BlueDIRECT: the most efficient form of direct injection

The second generation of direct petrol injection made its debut in the CLS 350 CGI introduced in 2006. The six cylinder unit was the world’s first petrol engine with piezo-electric direct injection and spray-guided combustion, and as such achieved a fuel saving of around ten percent compared with its predecessor with port injection.

Now the third generation of direct petrol injection is celebrating its world premiere, this time in the new CLS. Christened BlueDIRECT, this innovation is helping to establish the V-engines of Mercedes-Benz as the world benchmarks, enabling a further reduction of 20 percent in fuel consumption to be achieved solely through in-engine measures.

The key data of the CLS 350 BlueEFFICIENCY include: 225 kW/306 hp (plus 10 kW), 370 Nm (plus 5 Nm), fuel consumption of 6.8 litres per 100 km (minus 2.3 litres). The CLS 350 BlueEFFICIENCY accelerates from 0 to 100 km/h in 6.1 seconds, and achieves a top speed of 250 km/h.

The V6 petrol engine with BlueDIRECT technology in the CLS 350

BlueEFFICIENCY differs from its predecessor in the following key areas:

- 60° cylinder angle and omission of balancer shaft

- Extended lean-burn operation, lean-burn system with load monitoring from pressure information, new combustion system operating modes

- Multi-spark ignition

- Resonance intake manifold

- Latest generation of piezo injectors

- Enhanced cooling circuit control and optimisation

- Enhanced oil circuit control and optimisation

- Increased output and torque

BlueDIRECT: third-generation direct injection

Direct petrol injection with spray-guided combustion, which Mercedes-Benz was the first car manufacturer to introduce in series production, has been developed further by the engineers into third-generation direct petrol injection with spray-guided combustion.

The system pressure is now up to 200 bar and is variably optimised according to the engine’s characteristic map. Completely newly developed piezo-electric injectors allow up to five injections per power stroke for the best possible mixture formation, while multi-spark ignition helps to ensure reliable combustion of the mixture.

Further details on direct injection can be found in the section “Under the microscope: lean-burn mixture”.

While the V6 unit is a naturally-aspirated engine, the new, technically similar V8 engine, which is due to be introduced during 2011 as the CLS 500 BlueEFFICIENCY, features biturbocharging for the first time, previously only seen in the 12-cylinder engine used in the S-Class.

It too has direct injection but was designed for countries without sulphur-free fuel and is therefore run in a homogenous mode through the engine’s entire characteristic map.

Despite a significantly smaller displacement (4633 cc; previously 5461 cc), the eight-cylinder unit made considerable gains in terms of output (300 kW/408 hp; previously 285 kW/388 hp) and torque (600 Nm; previously 530 Nm).

At the same time consumption has been significantly reduced. It is expected to achieve a saving in the region of 25 percent. Further details on the new engine generation can be found in the section “Under the microscope: innovative engine technology”.

The petrol engines of the new CLS at a glance

| Model | CLS 350 BlueEFFICIENCY | CLS 500 BlueEFFICIENCY | |

| Cylinder arrangement/ number | V6 | V8 | |

| Displacement | [cc] | 3498 | 4633 |

| Rated output | [kW/hp] at [rpm] | 225/306 6500 | 300/408 5250 |

| Rated torque | [Nm] at [rpm] | 370 3500 – 5250 | 600 1800 – 3500 |

| Fuel consumption combined | [l/100 km] | 6.8 | ≤9.0* |

| CO2 emissions combined | [g/km] | 159 | ≤210* |

*provisional figures

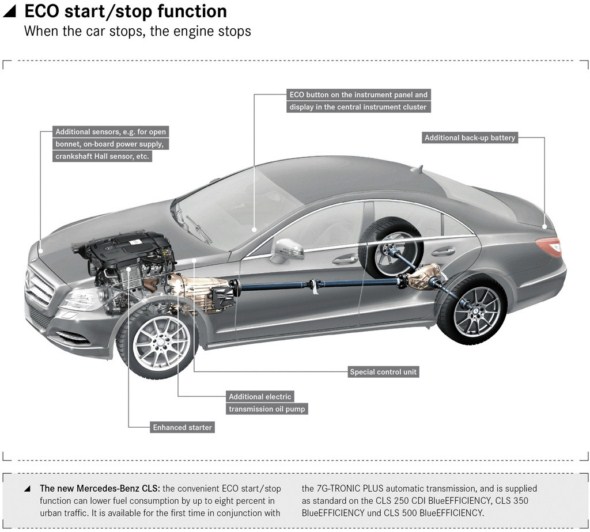

ECO start/stop function: significantly reduced consumption in urban traffic

When the car is at a standstill, the engine does not need to be running and therefore does not need to consume fuel. Recognition of this essentially simple fact is behind the ECO start/stop function, which is available for the first time in the CLS with the 7G-TRONIC PLUS automatic transmission.

In order to implement the auto start and auto stop function with a very high level of comfort in a Mercedes-Benz, it has been necessary to develop complex control logistics and a series of new or modified components, such as a Hall sensor for the crankshaft and a high-output starter motor.

That’s because Mercedes drivers should only really notice the forced breaks taken by the engine when they are at the filling station – thanks to consumption figures which are up to eight percent lower in urban traffic and five percent lower in the ECE consumption cycle.

In the case of the CLS 250 CDI BlueEFFICIENCY, CLS 350 BlueEFFICIENCY and CLS 500 BlueEFFICIENCY models, the ECO start/stop system is fitted as standard.

More details can be found in the section “Under the microscope: ECO start/stop function”.

Smaller tank, same range

Because the new CLS models consume significantly less fuel, it has been possible to reduce the filling volume of the fuel tank in the four and six-cylinder models to 59 litres.

The 80-litre tank comes as standard on all V8 engines, and is offered as an optional extra on all CLS variants with the 59-litre tank.

7G-TRONIC PLUS automatic transmission available for the first time with the four-cylinder diesel

All CLS models come with the 7G-TRONIC PLUS automatic transmission as standard, for which the torque converter and main transmission have been developed and improved further with regard to fuel consumption and comfort.

The new generation of the torque converter provides an improved dynamic response, better durability and reduced noise and vibration levels thanks to a new hydraulic circuit, as well as enhanced dampers and torque converter housing.

The extreme wheel-slip reduction of the torque converter housing, combined with larger mechanical damper de-coupling, helps to reduce consumption significantly.

In addition, the gearshift program in ECO mode has been changed in favour of lower engine rpm at cruising speeds.

With friction-optimised bearings and gaskets, as well as a new automatic transmission oil (FE-ATF) with reduced viscosity combined with an enhanced additive package, the transmission itself also contributes towards reducing consumption.

When the cooling limits are observed, the increased service life of the new oil results in new oil change intervals of every 125,000 kilometres (new) instead of once every 50,000 kilometres (old).

The improved electrohydraulic assembly of the transmission and the new friction-reducing materials used on certain transmission parts, combined with optimised software, also lead to better shift quality.

The CLS will also be available with 4MATIC all-wheel drive for the first time in the autumn of 2011.

Two new operating modes for extended lean-burn operation

The latest-generation piezo injection technology makes multiple injection possible in even the tiniest quantities. As a result, Mercedes-Benz engineers have been able to extend the lean-burn operation of the new generation of V-engines across an even wider range of the characteristic map while also providing two additional operating modes:

- “Homogeneous stratified combustion” (HOS): this is a combination of homogeneous lean-burn and classic stratified combustion. With the engine unthrottled (throttle valve open), the first injection is sprayed into the intake stroke, forming a homogeneous basic mixture. Actual “stratified” injection takes place during the compression stroke before ignition and is a single or double injection depending on the characteristic map.

- “Homogeneous split” (HSP): in this homogeneous combustion process, more than 95 percent of the fuel is singly or multiply injected, followed by a very small “ignition” injection to stabilise combustion. This is used when combustion conditions are difficult.

In order to ensure that the lean mixture is also ignited reliably at all times, the third-generation direct injection system also features “rapid multi-spark ignition” (MSI).

Following the first spark discharge and a brief combustion period, the coil immediately above the corresponding spark plug is recharged rapidly and a further spark is discharged.

The MSI system enables up to four sparks to be discharged in rapid succession within one millisecond, creating a plasma with a larger spatial expansion than conventional ignition.

The extension of the lean-burn operating phases means that a suitably light touch on the accelerator and a consistent driving style now make it possible to attain extremely favourable fuel consumption figures at speeds up to about 150 km/h.

A close look at the new BlueDIRECT engines

Lower fuel consumption, greater smoothness

Both the new V6 and the new V8 from Mercedes-Benz have aluminium crankcases, pistons and cylinder heads. The crankshaft, connecting rods and valves are of special forged steel.

Through thoroughgoing lightweight design and intensive fine-tuning of details, engine friction also was reduced compared with the previous engine, by 28 percent.