Mercedes-Benz presents a new six-cylinder engine

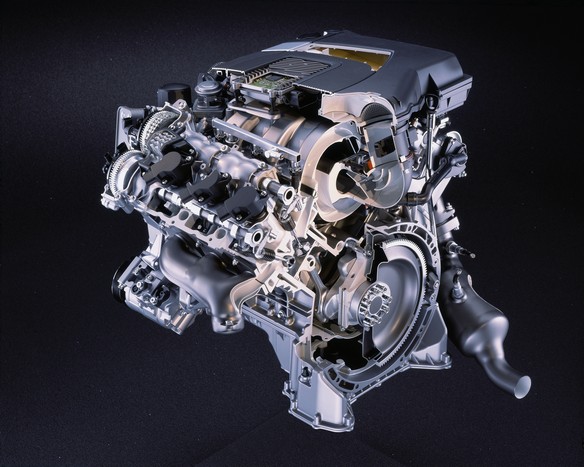

With an output of 200 kW/272 hp and 350 Newton metres of torque, the new Mercedes six-cylinder unit is one of the most powerful V6 engines in its displacement class.

The maximum torque is already available from 2500 rpm and remains constant over a wide engine speed range up to 5000 rpm, providing powerful acceleration and rapid sprints.

The aluminium engine excels with a unique package of technical features. For the first time in a V6 engine it has variable intake and exhaust camshaft adjustment, which increases the output and torque while contributing to fuel economy.

A two-stage intake manifold, tumble flaps in the intake ducts and an intelligent heat management system are further technical highlights in this new six-cylinder engine for the future SLK-Class.

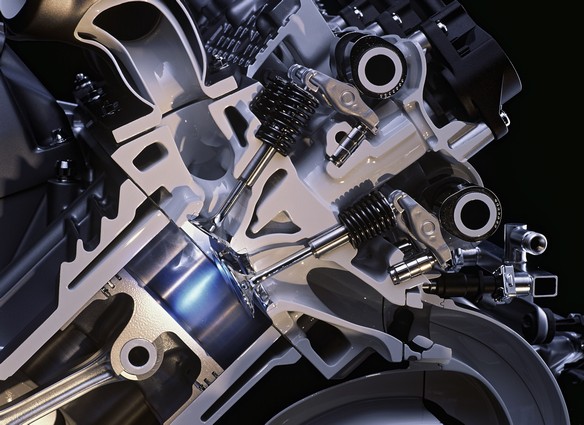

The variable, continuous camshaft adjustment system controls the 24 valves in the aluminium cylinder heads.

It helps to ensure that the valves open and close at the most favourable time in any driving situation, significantly improving the charge cycle in the cylinders and reducing energy losses.

As a result this technology reduces fuel consumption under partial load, while ensuring an optimal supply of fresh gas to the combustion chambers under full load.

The new Mercedes six-cylinder is the world’s first V6 engine with variably adjustable intake and exhaust camshafts.

Tumble flaps in the intake ducts for an optimal combustion process

Mercedes engineers have configured and optimised all the air ducting components with the help of sophisticated airflow simulations.

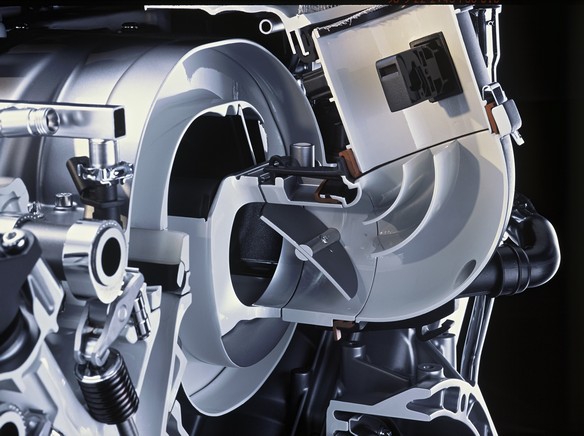

The magnesium intake module has likewise been optimised in terms of flow characteristics. The length of the intake manifold can be varied according to the engine speed to achieve the best possible torque and output.

From 1500 rpm the new V6 already develops approx. 87 percent of its maximum torque of 350 Newton metres.

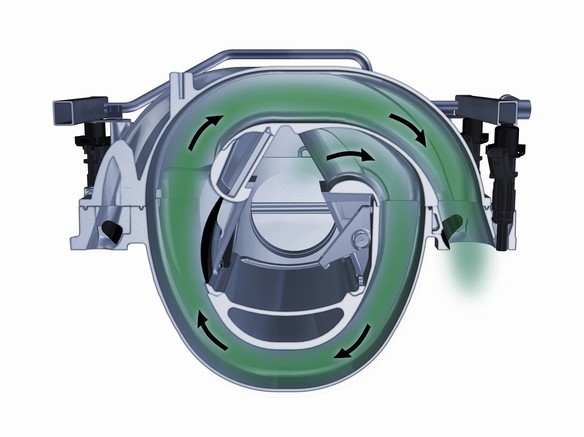

The intake ducts are equipped with newly developed tumble flaps which improve the intake process and combustion of the fuel-air mixture.

These pivot open under partial load, increasing the turbulence of the gas flow in the combustion chambers. Under higher engine loads the tumble flaps are completely recessed into the intake manifold.

Thanks to the use of these innovative tumble flaps, the fuel consumption of the V6 engine is reduced by up to 0.2 litres per 100 kilometres depending on engine speed – with a significant improvement in smoothness.

An intelligent heat management system also contributes to fuel economy. Mercedes engineers have developed a new, electronic map-controlled thermostat which is active in all engine operating situations.

It directs the heat flows inside the powerplant in such a way that the engine oil and coolant are always at the best possible temperatures.

Exhaust emissions below the future EU 4 limits

By virtue of variable camshaft adjustment, tumble flaps in the intake ducts, internal exhaust gas recirculation, secondary air injection and other features, the exhaust emissions of the new Mercedes six-cylinder engine are already at a very low level during the combustion process.

In addition to these engine-specific measures, an efficient emission control system ensures that exhaust emission values remain below the stringent EU 4 limits coming into force in 2005.

Each of the two catalytic converters, which are located close to the engine, is monitored by two oxygen sensors.

Thanks to linear control these already deliver precise data to the engine computer during the warm-up phase, enabling this to regulate the engine so that the catalytic converters reach their normal operating temperature more rapidly.

Modern, lightweight power unit and designed-in engine sound

The crankcase and cylinder head of the new Mercedes six-cylinder are of aluminium.

The state-of-the-art, lightweight engine also has weight-reduced connecting rods, pistons and balancer weights which contribute to the exemplary smoothness of the unit.

Between the cylinder walls, a balancer shaft counter-rotates with the crankshaft and compensates the inherent vibration moments of the V6 unit.

The cylinder liners are in aluminium-silicon technology for particularly low friction, distortion and weight.

The acoustic properties were a further focus of the development work.

The aim of the Mercedes engineers was a specific reduction in engine noise, followed by the achievement of a sporty and sonorous six-cylinder exhaust note.

Very considerable technical effort was devoted to acoustic tests on practically all of the approx. 210 components in the new V6 engine.

Innovative intake manifolds of sound-absorbent woven nylon, a twin-cartridge air filter with integral resonators and numerous other refinements contribute to the exemplary level of noise comfort.

The acoustic specialists have achieved the typical sports car engine note by careful configuration of the exhaust system.