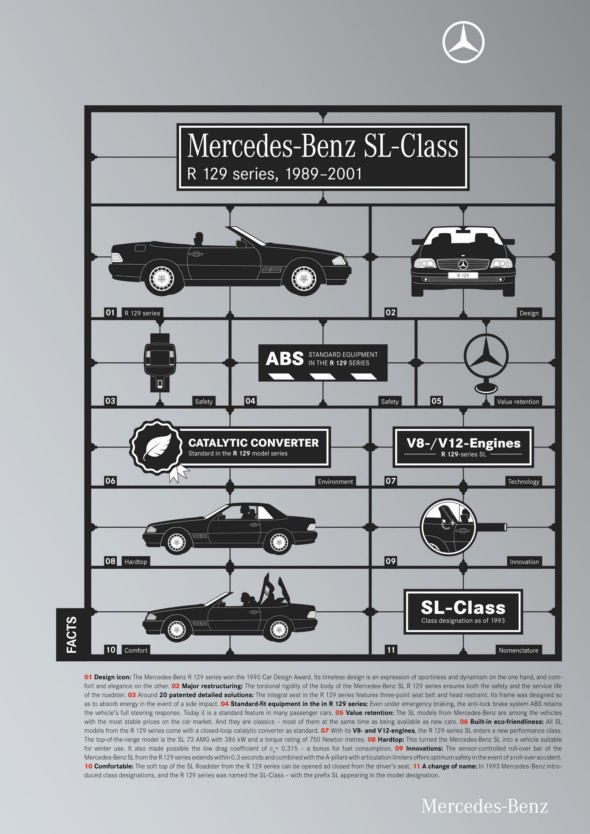

Modern classics: the Mercedes-Benz SL of the R 129 series (1989 – 2001)

- Design icon and innovation champion in one

- The Mercedes-Benz SL models are among the most inflation-proof vehicles

- A pleasure with the top up or down

Stuttgart – Quite a few cars from Mercedes-Benz are modern classics right from the beginning. Every model of the SL series is one: the series was established in 1954 by the 190 SL, which the company explicitly described as a touring sports car. At the same time the 300 SL Gullwing was presented, which can be put in the super sports car category. The fourth SL generation was the R 129 series built from 1989 to 2001, which set standards with its design and its many innovations.

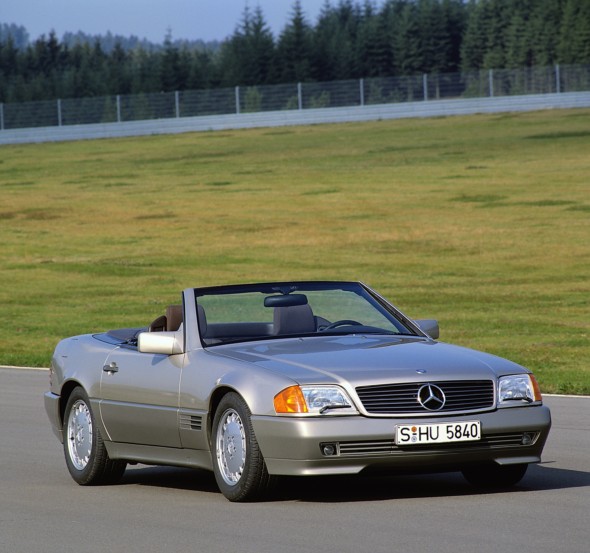

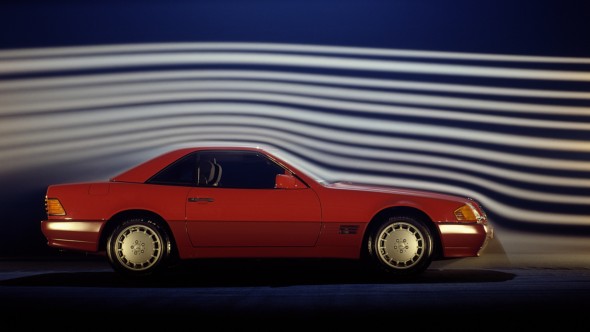

The design was the work of Bruno Sacco. It presents itself with the clear lines and strong sense of composure that characterises the appearance of Mercedes-Benz vehicles from the outgoing 1980s well into the 1990s. In the case of the SL series this is complemented by the attributes of a touring sports car – long bonnet, two seats, compact rear end, all packed into a slightly wedge-shaped body: it all goes to make the SL an icon on wheels that signals dynamism and sportiness, but also comfort and elegance as well. The perfection of its design was recognised early on: in 1990 the R 129 series was the recipient of the Car Design Award.

A driver of an SL makes a statement: it’s like travelling in assured style in an elegant, well-tailored suit. That the car is extremely comfortable and makes even long journeys pleasant is simply taken for granted – and enjoyed every kilometre of the way.

The high technological standard includes the recognised high safety level which the Mercedes-Benz engineers give the vehicles for the road. In the R 129 series this standard is manifested, for example, in the automatic roll-over bar which pops up in just 0.3 seconds when the car threatens to overturn.

Or in the integral seat featuring some 20 patented detailed solutions, which absorbs energy in a side impact and incorporates among other things the three-point seat belt with belt tensioner and the belt height adjustment coupled with the head restraint adjustment. The safety features, of course, included a newly designed body which was subjected to the severest crash tests and affords the occupants the highest level of safety.

From the outset the R 129-series SL was available with two six-cylinder engines and an eight-cylinder unit. As a matter of principle, they were fitted with catalytic converter as standard. Over the years the drive units repeatedly were adapted to the latest state of the art. In 1992 the 600 SL with twelve-cylinder engine caused a sensation – the SL entered an entirely new dimension of power. The most popular model in the twelve years in which the SL was built was the 500 SL, an eight-cylinder model.

The possibility of driving an SL with the top down is an important buying criterion for many people. In the R 129 series, for the first time Mercedes-Benz gave the touring sports car an automatic folding soft top that opens and closes within 30 seconds at the push of a button. The innovations included the draught-stop, which enables draught-free open-top motoring and which since then has established itself as the standard throughout the industry. The SL is made fit for year-round operation with the hardtop, which is made of aluminium and is standard equipment in the R 129 series.

A Mercedes-Benz SL in the R 129 series is the ideal modern classic – individual, but fully suitable for everyday use, and at the same time stable in value. The brand’s service organisation helps keep it that way: almost every part is available as a spare, and perfect maintenance services are ensured. And so this modern classic may one day – perhaps faster than one thinks – become a genuine classic.

Model history: the 129 series (1989 to 2001)

- Numerous innovations from the automatic roll-over bar to the integral seat

- A twelve-cylinder engine in the Mercedes-Benz 600 SL

- Official AMG versions available for the first time

At the 1989 Geneva Motor Show Mercedes-Benz presented an SL which was a new car in every respect. The first models were the 300 SL, 300 SL-24 and 500 SL. Internally the series was designated R 129. Unlike the predecessors, its production did not take place in Sindelfingen, but in Bremen, for capacity reasons. Straightaway the response was extremely positive, and shortly after the presentation it was foreseeable that the planned annual production capacity of 20,000 units would be stretched to the limit for years and delivery periods of several years would have to be accepted.

The SL face has captured a permanent slot in the Mercedes-Benz model hierarchy over the decades. The new SL re-interpreted the traditional basic shape of the grille: within the radiator grille, organically integrated into the bonnet, the Mercedes star was complemented by horizontal strips made of anodised aluminium. Chief designer Bruno Sacco had done an excellent job. The stylistically assured, no-frills lines of the slightly wedge-shaped body, the flared wheel arches for the wide-base tyres, the half-spoilers forward of the front wheels, a very slanted windscreen, the skilfully modelled rear end and the standard-fit light-alloy wheels produce an exceedingly harmonic overall effect.

The aerodynamic fine touches, including underbody and airflow through the engine compartment, added up to a fuel-saving, speed-increasing Cd of 0.32 with the hardtop mounted. A Cd figure of 0.40 was measured for the open-top car with closed side windows.

“Car Design Award”

Hardly a year after its launch the SL was decorated with the international Car Design Award. The SL was the top choice of an eleven-member jury of journalists from ten countries, assisted by a representative of the city of Turin and one from the Piedmont region. The jury stated as reason for the award: “In the Mercedes-Benz 300 – 500 SL the ensemble of safety innovations …, exemplary ergonomic solutions, and stringent adherence to the traditional design culture of the manufacturer’s brand is convincing. The new SL embodies the most valuable elements of up-to-date industrial design, without losing the flair that distinguishes every sports cabriolet.”

High torsional stiffness

The prerequisite for the proper operation of the fully automatic folding soft top under all conditions is the torsional stiffness of the body, which leaves nothing to be desired in this respect. To reduce the vibration and torsion characteristics typical of open-top cars, additional diagonal struts are fitted in the particularly critical areas of the body. In the front end the front axle carrier is connected with the door sills by two specially shaped struts. In the rear end two tubular struts between the door sills and the spare wheel recess serve the same function. Owing to these measures the torsional stiffness versus the previous model could be improved by around 30 percent and a saloon-like overall stiffness achieved.

New standards were set by this car also in the area of safety. The results of Mercedes-Benz’s rigorous frontal and rear-impact crash tests for the open-top vehicle were sensational and a clear proof of the scrupulous precision with which the developers had worked.

The resistance to side impact went far beyond what the law required and once again set trends for the sensible design of all details, for instance the overlapping of the doors with the sills, the cross-bracing beneath the seats, including the stiff sides of the transmission tunnel, or the high-strength steel tubes inside the A-pillars, which can withstand a roof impact. This two-shelled structure of the front roof frame in conjunction with the bonding of the windscreen to the body results in very great stability even if a one-sided load is applied to the roof frame.

An integral part of the safety concept is the automatic roll-over bar which was realised in the SL for the first time in an automobile and has the purpose of protecting the occupants’ survival space in the event the car overturns. So as not to impair open-top driving pleasure with a permanently installed, rigid rollbar, a flexible solution was realised which activates the roll-over protection only if needed. When not in use the safety bar, consisting of a U-shaped high-strength steel tube foam-padded with polyurethane, is deposited in front of the soft-top compartment, closing off the rear compartment towards the back and forming a level surface with the top well lid.

When a roll-over threatens, the sensor-controlled roll-over bar is electromagnetically triggered, raised into position by the force of pre-compressed springs within 0.3 seconds and secured by pawls. The high-strength centre pillars, connected over a large area with the rear longitudinal members, serve as basis for mounting and as support. In addition to automatic triggering in an emergency, by means of a switch the driver can choose to raise and lower the bar slowly, with a hydraulic element carrying out the action.

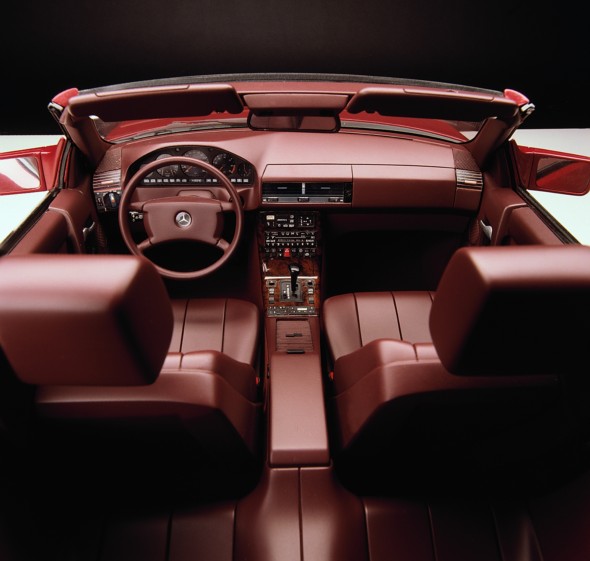

Extremely sturdy integral seats

The most advanced feature of the interior design were the integral seats of the SL, which are a technical masterpiece in their design and an important part of the safety concept. The seat frame and backrest are made of various special magnesium alloys executed in thin-wall casting technique.

They incorporate the three-point seat belt with belt tensioner, the belt height adjustment, coupled with the head restraint adjustment, and electric stepper motors for adjusting reach, height and tilt of the seat cushion and backrest. Another important feature is the automatic positive locking of the backrest. The resistance of the seat in a crash is many times higher than the possibly occurring forces.

Twenty patents for solutions to various details went into this seat; its creator received the Paul Pietsch Prize and high prize money in acknowledgement of his pioneering work in 1989.

Fully automatic folding soft top

The newly designed electro-hydraulic fabric top with which the SL is equipped as standard offers especially great operating convenience. Simply by operating a switch, within 30 seconds the soft top can be opened, folded and deposited in the narrow soft-top compartment, or taken out of the compartment and closed. Simultaneously, the side windows and the roll-over bar are lowered and then returned to their starting positions. Up and closed, the top is taut and smooth in all directions – the vacuum that exists above the roof while on the go should not cause the top to balloon after all, and perfect operation of the roll-over bar under the closed soft top also must remain guaranteed.

The energy to operate the soft top is provided by an electrically driven hydraulic pump which is accommodated in the spare wheel recess together with the oil reservoir. The microprocessor-controlled motions are monitored with the aid of 17 limit switches, and the hydraulic system has 15 pressure cylinders and eleven solenoid valves.

The exemplary solutions include the draught-stop. Unlike the electro-hydraulic soft top it was not viewed as a high-tech marvel, but its development also involved attention to complex details. The draught-stop consists of a framed, breathable screen which can be quickly attached to the roll-over bar and, when raised, appreciably enhances ride comfort when the soft top is open by minimising wind noise and draught. With the draught-stop, leather jackets and caps for driver and front passenger are a thing of the past, as is tousled hair for the ladies. Even high speeds cause no draught problems anymore, and open-top driving at low temperatures becomes a real show. Today the innovative draught-stop, for which the inventors hold four patents, is practically a taken-for-granted component of many convertibles around the world.

The standard-fit hardtop now was made of aluminium, and despite larger windows weighed 34 kilograms or about 10 kilograms less than the coupé roof of the previous model. As it is, uncompromising lightweight design and the extensive use of high-strength sheet steel had enabled realising a bodyshell weight of 405 kilograms, which was only 20 kilograms more than that of the previous model despite substantial improvements in structural safety.

Electrically operated windows and the electro-pneumatic central locking system, both standard equipment in all SL models, serve comfort and convenience. The basic equipment of the 500 SL also included electric steering column adjustment for optimal adapting of reach, height and tilt to the driver.

A new suspension

The suspension conformed in principle to the familiar suspension design of the saloons of series 201 and 124. The new SL models thus had a coil-spring shock absorber strut independent front suspension with anti-dive control and wishbones, gas-filled shock absorbers and stabiliser, and a modified multi-link independent rear suspension with anti-squat and anti-dive control, coil springs, gas-filled shock absorbers and stabiliser. This guarantees excellent handling characteristics. Many components were adapted to the altered installation conditions and stresses and loads in the SL; the axle geometry also was matched to the special demands on the driving characteristics and comfort.

As an optional extra a newly developed auxiliary system also was available that represented the most advanced suspension technology realisable at the time and combined three subsystems with each other. The purpose of this level adjustment and regulation on front and rear axle was to maintain an always constant vehicle level with the engine running. The automatic speed-dependent level adjustment function lowers or raises the vehicle level depending on the actual speed; for driving on poor roads the level can be increased by 30 millimetres; at a speed of more than 72 km/h the normal level first can be set, and from a speed of more than 122 km/h then lowered by 15 millimetres. The third component, the Adaptive Damping System ADS, used adjustable shock absorbers and a complex electronic control to adapt the damping fully automatically, as needed, and within fractions of a second, to the driving state determined by five sensors. All in all the sprung mass vibrations are reduced depending on vehicle load, road condition and style of driving. This was virtually a preliminary stage of the active suspension which was developed to production standard in 1999 in the C 215-series coupé.

In keeping with their sports credentials, all models of the R 129 series were fitted as standard with 15-hole light-alloy wheels (diameter: 40.64 centimetres) and wide-base tyres size 225/55 ZR 16. The larger wheels compared with the previous models permitted installing large brakes appropriate to the improved performance of the SL. New were the front fixed-calliper disc brakes featuring four pistons, two pairs with different diameters. This design, used for the first time in a Mercedes-Benz passenger car, ensures even brake pad wear and better utilisation of the pad volume. The front and rear disc brakes are internally ventilated. The anti-lock braking system ABS was part of the standard configuration of all three models.

From September 1995 on the Electronic Stability Program ESP® was available for the SL 500 as an optional extra. It was standard equipment for the SL 600. From December 1996 on the six-cylinder models also could be fitted with ESP® if they were ordered with the electronically controlled automatic transmission available from June 1996. Another world first serving active safety also saw use at this time: the Brake Assist BAS, installed as standard from December 1996 in all models of the 129 and 140 series. BAS is able to detect emergency braking and, if need be, automatically build up the maximum brake boosting effect in shorter time than before. This distinctly reduces the braking distance of the vehicle. In early April 1998 the Electronic Stability Program ESP® was included in the standard equipment of the SL 500 and SL 60 AMG; in August 1999 it also became a standard feature in the two six-cylinder models, SL 280 and SL 320.

The first facelift

Visually and technically updated SL models were presented at the Frankfurt International Motor Show in September 1995. The facelifted variants were distinguished by a modified body design, more extensive standard equipment, and more refined engineering. The body design modifications were of a minor nature and ranged from redesigned front and rear bumpers, colourless glass covers for the front directional indicators, and a subtle change in the radiator grille, which now had six slats. The side skirts, like the bumpers, no longer were painted in a contrasting colour, but in the colour of the car, and had modified breathers, a prominent feature serving to identify the facelifted models. Other new items were the bichromatic tail lights with their uniform red appearance, and 12-hole light-alloy wheels, the standard for all SL models. As an optional extra a glass roof with sunblind was available; it could be fitted in place of the usual aluminium hardtop. In the interior, the door trim, steering wheel and seat design were modified.

Headlamps with xenon gas discharge lamps first introduced a few months earlier in the 210-series E-Class now also were available in the SL. Compared with conventional halogen headlamps the new xenon lamps were twice as intense and ensured better, brighter illumination of the roadway. Dynamic headlamp range adjustment prevents dazzling oncoming traffic.

A world first was introduced simultaneously in the SL-Class and

S-Class. As first carmaker Mercedes-Benz was able to present an improved cruise control which could regulate the speed down to 30 km/h; the updated SL models were fitted with this function as standard.

The second facelift

In 1998 the second facelift followed. But it involved only a few modifications to the design of the SL: purpose of the discreet stylistic touch-ups was to give the sports car an even more dynamic look. This was achieved with a slightly changed rear end in which the now monochromatic glass covers of the tail lights presented themselves in a gentler look with only three ribs. A new oval tailpipe trim for the exhaust system including adjustments on the bumper emphasised the sporty appearance. A round shape also was the dominant feature of the new exterior mirrors, which were adapted to the design of the SLK and were the most important external identifier of the facelifted models. The door handles and detachable body parts of the facelifted SL models had a high-gloss finish in the colour of the car. The size and design of the wheels also were modified: the SL models now had newly designed five-hole light-alloy wheels and size 245/45 ZR 17 tyres as standard.

Proven engine technology right from the start

All three engines of the original SL portfolio in the R 129 series feature a closed-loop catalytic emission control system as standard. The entry-level engine was the two-valve-per-cylinder six-cylinder engine (M 103) in the 300 SL (1989 to 1993) with an output of 140 kW. It had already served well in the saloons of the 124 and 126 series, but was revised for use in the SL. The most important improvements were a redesigned combustion chamber, which reduced the emissions of unburned hydrocarbons, and a modified emission control system. By eliminating the close-coupled primary catalytic converter, which was subject to high thermal stresses, and enlarging the cross-section of the exhaust pipes and the now two-pipe catalytic converter it was possible raise the rated output of the engine from 132 kW to 140 kW. The top speed was 228 km/h; 9.3 seconds was the figure stated for 0 to 100 km/h acceleration.

From 1989 to 1993 there was also the 300 SL-24 model featuring a newly designed four-valve-per-cylinder six-cylinder engine (M 104). This engine is based on the M 103, and its parts are mostly identical with those of the two-valve counterpart. New were the four-valve cylinder head and map-controlled electronic intake camshaft adjustment, used for the first time at Mercedes-Benz. In conjunction with a higher compression ratio and an electronic ignition system with anti-knock control, the result was a 29 kW increase in output over the M 103 to 170 kW. The performance of the 300 SL-24 was thus noticeably sportier despite almost identical fuel consumption (top speed: 240 km/h, 0 to 100: 8.4 seconds), but had to be bought at an additional cost of almost DM 10,000. The successors to these two models in the years 1993 to 1998 were the SL 280 (2.8 litres displacement, 142 kW) und SL 320 (3.2 litres displacement, 170 kW), both with four-valve-per-cylinder six-cylinder engines from the M 104 series.

The car that attracted particular attention at the 1989 Geneva Motor Show was the 500 SL, which as top-of-the-range model had a 240 kW 5.0-litre four-valve-per-cylinder V8 engine (M 119), making it the most powerful Mercedes-Benz production car at the time. The design of this engine was based on the 5.0-litre M 117 light-alloy engine, which had stood the test of over ten years’ time. Crankcase, crankshaft and connecting rods were extensively modified to obtain the higher output figures. The two four-valve cylinder heads were of new design and had adjustable intake camshafts like the four-valve-per-cylinder six-cylinder. Decisive for the marked increase in output (plus 60 kW), along with conversion to the four-valve-per-cylinder technology, were the anti-knock control, a new two-box air filter with reduced suction resistance, and, not least of all, changes in the emission control system: like the two six-cylinder units the four-valve V8 had no more primary catalytic converter, and a two-pipe catalytic converter with a larger cross-section. This power potential gave the 500 SL impressive performance to outclass its predecessor: from a standing start the top-of-the-range model sped from 0 to 100 km/h in 6.2 seconds; the top speed was electronically limited to 250 km/h.

In autumn 1992, when the 600 SL appeared, the engine of the 500 SL was slightly revised. The version of the four-valve V8 with Bosch

KE-Jetronic used previously was replaced by the “standard-deck engine” which was already being used in the 500 E (W 124) and in the saloons and coupés of the S-Class (140 series). Characteristic features of the new engine were the modified crankcase, whose deck height was now identical with that of the 4.2-litre unit, and the electronic injection system Bosch LH-Jetronic with mass air flow sensor. As in the V12 engine, full load enrichment was dispensed with here to reduce the pollutant emissions – a measure affecting not only the SL, but all other car models with V12 and V8 engines too. In the case of the 5.0-litre engine this meant the loss of 4.4 kW output (now 235 kW). But for all practical purposes this hardly made itself felt in the performance.

From June 1993 onwards the 500 SL was called the SL 500 owing to a reform of the nomenclature; this reversal of the model designations applied as a matter of principle to all Mercedes-Benz models.

The twelve-cylinder arrives

In October 1992 the dream of many a friend of the SL came true: three-and-a-half years after the presentation of the R 129 series, it too was now available with the 6.0-litre V12 engine, which had already proved itself in the saloons and coupés of the 140-series S-Class. To further reduce pollutant emissions the injection system was modified and full-load mixture enrichment dispensed with. In the 600 SL, known from June 1993 as the SL 600 and, all told, available from 1992 until 2001, the most powerful engine in the passenger car sales range mobilised 290 kW and made brilliant performance possible: at 6.1 seconds the acceleration was slightly better than that of the 500 SL; the top speed likewise was governed at 250 km/h. The twelve-cylinder was a model of smoothness and turbine-like power delivery. Above all, its imperturbability in high speed regions and the impressive and simultaneously refined manner in which it reached top speed characterised the 600 SL.

The large extra charge of more than DM 60,000 compared with the 500 SL made its ownership a matter of prestige. But for that the new top model of the series was fitted as standard with a whole range of extras that only could be had at an additional charge in the 500 SL. Apart from the Adaptive Damping System ADS with level control on the front and rear axle the basic equipment comprised, for example, cruise control, automatically dimming interior mirror, headlamp cleaning system, automatic climate control, leather appointments and seat heating. Externally, only the model plate and two “V12” emblems in the vicinity of the air outlets behind the front wheel cut-outs distinguished the 600 SL from its sister models.

The 1995 facelift brought improvements to the engines and transmissions of the SL 500 and SL 600 models. From September 1995, both featured a five-speed automatic transmission with torque converter lockup clutch, a completely new development that replaced the previous hydraulically controlled transmission. The heart of this technical wonder was an electronic transmission control that quickly and automatically adapted shifting behaviour to every driving situation and permanently exchanged data with the electronic engine management. Apart from these forward-looking innovations the automatic transmission was appreciably more compact and lighter than comparable five-speed units. The engines were revised once more to cut fuel consumption and pollutant emissions further. For this purpose the 5.0-litre V8 engine got a modified crankshaft, optimised valve timing, lighter pistons, individual ignition coils for each cylinder as well as an improved electronic engine management system called Motronic ME 1.0. Fewer changes were made to the design of the V12 power plant and merely concerned the configuration of the ignition coils and the electronic engine management. As a result of the various modifications to the engine and the use of the new automatic transmission, the fuel consumption of the SL 500 and SL 600 could be reduced by ten percent with output remaining unchanged.

From June 1996 the new electronically controlled automatic transmission also was available for the six-cylinder models SL 280 and SL 320 – as an optional extra for the 2.8-litre variant, as standard equipment for the SL 320.

V-engines instead of in-line engines

The 1998 facelift ushered in the V-engine generation with six and eight cylinders, which took the place of the six-cylinders of the M 104 series and the V8 unit of series M 119 also in the SL. The engines featured three-valve-per-cylinder technology and dual ignition for better emission values. They also excelled in lower cost of production.

Outputs ranged from 150 kW in the SL 280 (M 112, top speed 232 km/h, 0 to 100 km/h in 9.5 seconds) to 165 kW in the SL 320 (M 112, 238 km/h, 8.4 seconds) to 225 kW in the SL 500 (M 113, 250 km/h, 6.5 seconds). The top-of-the-range SL 600 continued to use the tried-and-tested twelve-cylinder engine (M 120) with 290 kW. The SL 280 was now the sole model of the series still available with a five-speed manual transmission, all sister models had automatic transmission as standard.

Mercedes-AMG GmbH

Anyone still not satisfied with the output and prestige afforded by the eight-and twelve-cylinders could turn to AMG in Affalterbach, not far from Stuttgart. Since 1990 a cooperation agreement existed between AMG and Daimler-Benz AG. Effective 1 January 1999 AMG then became a 51-percent subsidiary of the then DaimlerChrysler AG and took the name Mercedes-AMG GmbH.

AMG offers power-hungry customers several alternatives. When the first vehicles developed on the basis of the cooperation agreement came out on the market in 1993, the first SL model was the SL 60 AMG (M 119, 6.0-litre V8, 280 kW), which was sold until 1998; a purely AMG version with the same engine had existed earlier, from 1991 to 1993, under the name AMG 500 SL 6.0.

Models SL 55 AMG (M 113, 5.5-litre V8, 260 kW, 1999 to 2001) and the top-of-the-range model with twelve-cylinder engine, the SL 73 AMG (M 120, 7.3-litre V12, 386 kW, 1999 to 2001), followed. The latter’s maximum torque of enormous 750 Newton metres propelled the vehicle from 0 to 100 km/h in just 4.8 seconds. The top speed of both cars was electronically limited to 250 km/h, but the limit could be neutralised on customer request. All power transmission components of the AMG models, from automatic transmission to rear axle, were adapted to the higher loads.

The AMG bodystyling package with integral fog lamps in the bumper emphasises the tense dynamics of the sports car even more, without laying hand on the clear lines of its design. The large AMG light-alloy wheels (diameter: 45.72 centimetres) added a further dash of unmistakable sportiness to the looks.

The special models of the R 129 series

Special SL models became available for the first time in the R 129 series. Extended and modified appointments distinguished them from the series-produced cars. This made them exclusive, offered a price advantage, and simultaneously boosted SL sales. Between 1995 and 2001 there were 17 special series built in differing numbers, from ten to 1515 units.

In 1995 the “Special Edition” with a production run of 630 units debuted. It was available as SL 280, SL 320 and SL 500. The distinguishing features included an exterior finished in brilliant silver, combined with red soft-top fabric.

In the same year the special series “Mille Miglia” was released. It served as VIP and escort vehicle at the Mille Miglia Storica in Italy. There were ten Mille Miglia units in all based on the Special Edition, but with further distinctive features such as an unobtrusive black-and-white chequered flag on the ornamental grilles of the front wings.

In 1998 another “Special Edition” arrived, available for all models except the SL 60 AMG; 500 units were built. Obsidian black was chosen as exterior paint finish; the leather seats were in designo red with black topstitching. The SL 280 was given the five-speed automatic transmission as standard equipment.

A further small VIP series was released on the occasion of the 1999 Mille Miglia Storica. It was based on the SL 55 AMG and twelve units were built. One year later the “SL Edition” stimulated the brand’s sports car sales; 708 units were built – the third-highest volume for an R 129 SL special series, and available as SL 320 and SL 500. The “Final Edition”, also dating from 2000 – 674 units were produced (all models with the exception of the SL 55 AMG and SL 73 AMG) – already heralded the approaching discontinuation of the series. Special VIP models again were available that year: the “Formula One Edition” (20 units) based on the SL 500 on the occasion of the Indianapolis Formula One race, and twelve units of the “Mille Miglia” of 2000. In 2001 the last special “Mille Miglia” model in the R 129 series followed, with thirteen units built this time based on the SL 600.

Various special series were created upon the request of individual markets, for instance the “40th Anniversary Roadster Edition” (USA, 1997, 750 units of models SL 320 and SL 500 and 35 AMG SL 60 Limited Edition models), in celebration of the coming of the Mercedes-Benz 300 SL Roadster in 1957; “designo MB UK” (England, 1998, 150 units), “designo MB Japan” (Japan, 1998, 67 units), “designo Vintage Edition UK” (England, 2000, 49 units, models SL 280 and SL 320), “designo Heritage Edition UK” (England, 2000, 49 units, models SL 280 and SL 320), “Silver Arrow Edition USA” (USA, 2001, 1515 units of model SL 500, 100 units of model SL 600) and “Silver Arrow Edition UK” (England, 2001, 100 vehicles, 500 SL model).

The successor arrives

In July 2001 the Mercedes-Benz SL 500, the first model of the new SL series, the R 230 series, had its world premiere. In the same month the last of a grand total of 204,940 units of the R 129 series rolled off the assembly line at the Bremen plant. In terms of overall volume the first SL manufactured in Bremen was not quite as successful as its predecessor from the R 107 series (237,287 units); but if average annual production is compared, the R 129 series with some 16,500 units takes a very clear lead. The most successful model of this series was the five-litre variant equipped with the four-valve V8 engine M 119, of which a total of 79,827 were produced from 1988 to 1998. The rarest variant by far is the SL 280 with V6 engine, which served as entry-level model for the series from 1997 and rolled off the assembly line only 1704 times.

Production figures for the Mercedes-Benz 129 series

| Models | Internal designation | Production period: preproduction to end | Number of units |

| SL 280 | R 129 E 28 | 1993 – 1998 | 10,319 |

| SL 280* | R 129 E 28 | 1997 – 2001 | 1704 |

| 300 SL | R 129 E 30 | 1988 – 1993 | 12,020 |

| 300 SL-24 | R 129 E 30 | 1988 – 1993 | 26,984 |

| SL 320 | R 129 E 32 | 1993 – 1998 | 32,223 |

| SL 320* | R 129 E 32 | 1997 – 2001 | 7070 |

| 500 SL / SL 500 | R 129 E 50 | 1988 – 1998 | 79,827 |

| 500 SL** | R 129 E 50 | 1997 – 2001 | 23,704 |

| 600 SL / SL 600 | R 129 E 60 | 1991 – 2001 | 11,089 |

| SL 55 AMG | R 129 E 55 | 1999 – 2001 | *** |

| SL 60 AMG | R 129 E 60 AMG | 1993 – 1998 | *** |

| SL 73 AMG | R 129 E 73 | 1999 – 2001 | *** |

| Total | 204,940 |

* With V6 engine

** With M 113 engine

*** Not separately documented