E-Class 4MATIC: a winter’s dream

Getting through the winter with supreme ease: 4MATIC permanent all-wheel drive for the E-Class

With snow, sleet, freezing fog, black ice, temperatures hovering around zero and severe frosts, the winter months hold some unpleasant road conditions in store for drivers. Despite these impediments, however, drivers of Mercedes models equipped with the 4MATIC permanent all-wheel-drive system can set off for the daily commute to work or savour the drive to the next winter wonderland with complete peace of mind. This is because the 4MATIC drive concept boasts formidable performance on snow-covered or icy roads. The E-Class 4MATIC in particular stands out for its blend of high traction reserves, excellent directional stability, peerless safety and exceptional comfort levels. Mercedes-Benz is demonstrating the capa-bilities of the Saloon and Estate models by staging a 4MATIC Workshop in extreme winter conditions on the Timmelsjoch high alpine road in Austria.

As with the 4MATIC system’s set-up on a dry or wet road, directional stability and, therefore, active safety are paramount at all times when wintry conditions prevail, too. The mechanical principle of the 4MATIC system, featuring a 45:55 torque split between the front and rear axles and a multi-disc limited-slip centre differential with a basic locking torque of 50 Nm, offers all the right ingredients. This basic design enables high levels of traction, as the dynamic shift in axle load toward the rear axle that occurs during acceleration is harnessed to deliver more drive torque to the rear wheels. However, the multi-disc differential lock is also able to shift the drive torque between the front and rear axles, varying the split between 30:70 and 70:30 as the road conditions dictate. Consequently, intervention by the ESP®, 4ETS or ASR electronic control systems can be delayed for as long as possible and the bulk of the drive torque converted into tractive power, even on slippery roads. All control system interventions go virtually unnoticed, yet drivers still know straight away if they are driving on the limit: in such instances, a yellow warning symbol flashes in the instrument cluster as ahighly visible prompt to adapt their driving style to the road conditions.

The drive mechanism’s permanently engaged design offers key advantages over other systems that first need to diagnose a lack of grip before activating the 4×4 drive. The 4MATIC on the E-Class will have already made use of this valuable time to start transmitting drive torque via the wheels to the road.

E-Class 4MATIC: stable handling on snow and ice

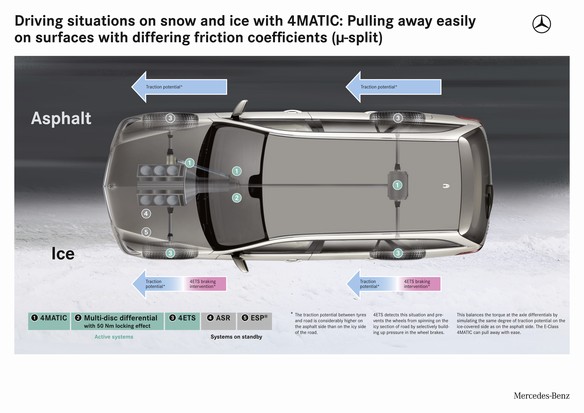

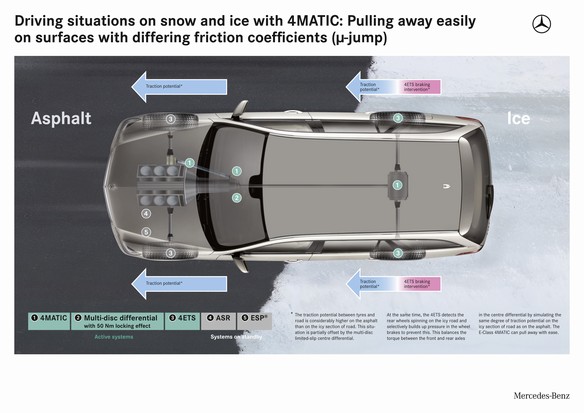

When pulling away in wintry conditions, the E-Class 4MATIC models are designed to develop maximum traction. To this end, certain road conditions are automatically detected and the interventions of the 4ETS electronic traction control system adjusted so as to achieve the greatest possible acceleration while minimising wheel slip, ensuring optimum directional stability in the process. This strategy also allows the vehicle to pull away under the most adverse conditions, such as when one side of the vehicle is on an icy slope (µ-split) or both wheels on the front or rear axle have limited grip (µ-jump).

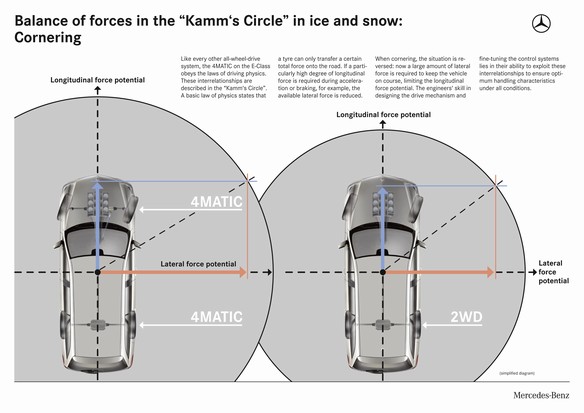

On twisting roads covered with snow and ice, vehicle stability is primarily controlled by the ASR acceleration skid control system’s regulation of engine torque. The ASR control thresholds are adjusted according to the driving situation based on the vehicle’s longitudinal and lateral dynamic readings as continuously measured by the ESP sensor system. If vehicle stability is to be maintained, the longitudinal force when cornering must be controlled by means of engine torque regulation in such a way that there are sufficient reserves of lateral force at all times. In order to comply with this physical correlation, when cornering on road surfaces with a low friction coefficient the control thresholds for engine torque regulation at the wheels on the outside of the bend are reduced considerably so that the tyres can develop sufficient lateral force.

4MATIC: cutting-edge technology breaks new ground

The 4MATIC powertrain in the E-Class is one of the best-performing permanent all-wheel-drive systems on the market. The basic design concept, with the engine installed longitudinally and the integral transmission and transfer case unit, produces a compact, lightweight arrangement that minimises frictional losses, heralding a number of benefits compared to other passenger car systems with a transverse power unit and selectable 4×4. Fuel consumption, for instance, is a mere between 0.2 and 0.6 litres more per hundred kilometres than on a com-parable model with conventional drive, while vibration and acoustic comfort meet the high standards expected of the E-Class.

E-Class synonymous with supreme ride comfort in winter too

Mercedes-Benz achieves the standard of ride comfort which all versions of the E‑Class are renowned for courtesy of the highly sophisticated DIRECT CONTROL suspension with adaptive shock absorbers, an intelligent body design with excellent rigidity, plus enhanced seats which are also available with massage and climate control functions. The weight-optimised DIRECT CONTROL system, featuring a three-link front suspension and multi-link independent rear suspension, automatically adapts to the changing driving situation by varying the damping forces, resulting in a substantial improvement in ride comfort. The air suspension system – optional for all 4MATIC models and standard on the E 500 4MATIC – is combined with a continuously variable, electronically controlled damping system that processes a series of sensor signals and controls each wheel individually. So, not only do Mercedes customers experience the best in ride comfort, they reap the benefits of excellent handling safety and sporty agility too.

Carefully balanced control of the interior climate is especially important in the winter. This is why Mercedes-Benz offers THERMOTRONIC luxury automatic climate control for the E-Class. Apart from regulating the climate separately for the driver, front passenger and passengers in the rear, this system allows individual pre-settings to be programmed too. It furthermore includes a pollutant sensor which automatically switches to air recirculation mode if it detects any sudden increase in the carbon monoxide or nitrogen oxide levels in the outside air – when driving through a tunnel, for instance. Another highlight of the THERMOTRONIC system is the residual heat function: pressing the “Rest” button heats or ventilates the passenger compartment for around 30 minutes when the engine is switched off. The E-Class is equipped as standard with THERMATIC, a two-zone automatic climate control system. Here, the interior air is kept clean by a large, hermetically sealed fine-particle combination filter which is 96 to 98 percent effective. Thanks to the activated-charcoal coating, gaseous substances can also be filtered out by the fine-particle combination filter.

THERMATIC and THERMOTRONIC heat up the passenger compartment of the E‑Class extremely efficiently, even after a cold start on winter mornings. This is thanks to a heating output of eleven kilowatts, equivalent to the capacity of the central heating system in a modern family home. On the diesel models, a heat exchanger with six integral PTC heating elements (PTC = Positive Temperature Coefficient) is also activated when the outside temperature falls below a certain level in order to boost the effect of the main heat exchanger with an electrical output of around 1200 watts. The assistance from the PTC heater is necessary due to the high thermal efficiency of today’s CDI engines, which is precisely what makes them so economical and means that they dissipate considerably less heat to the coolant under partial load conditions than conventional engines.

Mercedes offers 4MATIC in 52 passenger car models

The Mercedes-Benz all-wheel-drive line-up encompasses 52 passenger car models across nine model series and offers an impressively wide choice: besides the E-Class and the C-Class, which likewise comes in both a saloon and an estate variant, the 4MATIC portfolio is enriched by models from the S-Class, CL luxury coupé and R‑Class touring SUV ranges too. There is also the compact GLK as well as the GL‑Class and M-Class off-roaders. Still going strong after 30 years in production, the G-Class truly comes into its own off the beaten track and continues to rank as one of the best cross-country vehicles in the world.

All-wheel drive development expertise since 1903

There is a reason why Mercedes engineers are so skilled in the development of groundbreaking all-wheel-drive concepts. The history of all-wheel drive at

Mercedes-Benz dates all the way back to 1903. Since then, the accepted maxim has been that all-wheel drive is the best technology for making quicker and safer progress under the most adverse conditions. Over the course of the years it has been successfully employed in a variety of Mercedes-Benz models. Some models, such as the G-Class and the Unimog, have attained legendary status all over the world. But all-wheel drive has its benefits in everyday operation on asphalt roads too, as demonstrated by the 4MATIC saloons from Mercedes-Benz. The innovative drive concept received its saloon premiere in the W 124 E-Class model series back in 1987. The 4ETS system made its debut aboard the M-Class in 1997. Mercedes-Benz has therefore amassed a wealth of experience with these electronic control systems – more in fact than any other car manufacturer.

The automatic drive for wintry road conditions: Sure, predictable handling, plus impressive driving dynamics

As with the 4MATIC system’s set-up on a dry or wet road, the directional stability and, therefore, the active safety of the E-Class 4MATIC models are paramount at all times when wintry conditions prevail, too. The mechanical principle of the 4MATIC system, featuring a 45:55 torque split between the front and rear axles and a multi-disc limited-slip centre differential with a basic locking torque of 50 Newton metres, offers all the right ingredients. This basic design enables high levels of traction, firstly because the dynamic shift in axle load toward the rear axle that occurs during acceleration is harnessed to deliver more drive torque to the rear wheels. Secondly, the multi-disc differential lock is also able to shift the drive torque between the front and rear axles, varying the split between 30:70 and 70:30 as the road conditions dictate. Consequently, intervention by the ESP®, 4ETS or ASR electronic control systems can be delayed for as long as possible and the bulk of the drive torque converted into tractive power, even on slippery roads. All control system interventions go virtually unnoticed, yet drivers still know straight away if they are driving on the limit, as a yellow warning symbol will flash in the instrument cluster. This serves as a prompt to adapt the driving style to the road conditions.

The drive mechanism’s permanently engaged design offers key advantages over other systems that first need to diagnose a lack of grip before activating their 4×4 technology. The 4MATIC on the E-Class will have already made use of this valuable time to start transmitting drive torque via the wheels to the road.

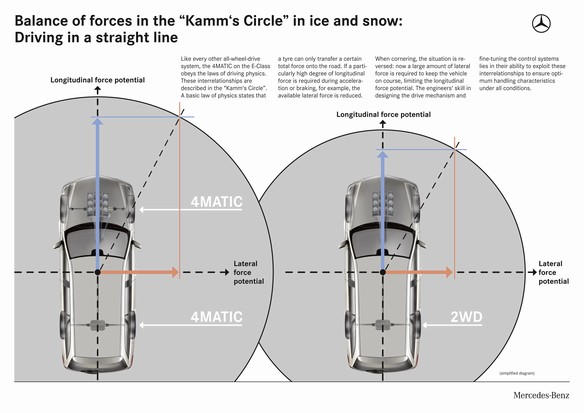

Kamm’s Circle describes the limits of driving physics

Like any other all-wheel-drive system, the 4MATIC on the E-Class has to abide by the laws of driving physics, whose interrelations are clearly illustrated in what is known as the “Kamm’s Circle”. The fundamental rule is that a tyre is only able to transfer a certain level of overall force to the road surface. If a particularly high degree of longitudinal force is required during acceleration or braking, for example, the available lateral force is reduced. When cornering, the reverse applies: now a large amount of lateral force is required to keep the vehicle on course, while the longitudinal force potential is restricted. The engineers’ skill in designing the drive mechanism and fine-tuning the control systems lies in their ability to exploit these correlations in such a way as to ensure the best possible handling characteristics under all conditions. The frictional coefficient µ describes the physical grip between the tyres and the road surface. This figure is high on a dry road (µ = 0.9) and low on a snow-covered road (µ = 0.3).

Despite all the engineers’ efforts, it is ultimately the drivers themselves who determine how safe they are out on the road. They should always adapt their driving style in accordance with the wintry conditions and ensure that their vehicle is suitably equipped; winter tyres are absolutely essential.

An engineering genius: Professor Wunibald Kamm

Professor Wunibald Kamm (born 26 April 1893, died 11 October 1966), after whom the “Kamm’s Circle” is named, worked under Paul Daimler and Ferdinand Porsche in the racing engines department of the Daimler-Motoren-Gesellschaft (DMG) from 1922 until 1925. He then moved to the German Experimental Institute for Aviation in Berlin-Adlershof where he gained valuable experience. In 1930, Professor Kamm founded and became head of the Research Institute for Motor Transport and Vehicle Engines at the Stuttgart College of Technology. During this time, Professor Kamm developed a pioneering testing ground for motor vehicles including a 1:1 wind tunnel, as well as researching and describing dynamic driving processes. This led him to devise the “Kamm’s Circle”. In 1952 he was appointed head of the Battelle Institute’s Mechanical Engineering faculty, specialising in automotive engineering. Professor Kamm’s induction into the “Automotive Hall of Fame” on 6 October 2009 recognises his status as one of the world greats of the automotive industry who have made “major contributions to the advancement of the automobile through their ingenious creations, unerring dedication and valuable inventions”. Other famous figures who have received this honour and have close links to Daimler AG include Gottlieb Daimler, Carl Benz, Béla Barényi, Wilhelm Maybach, Ferdinand Porsche and Rudolf Diesel. The work of Professor Kamm, who maintained close ties to Daimler AG throughout his lifetime, earned him further accolades too: on 1 August 1958 he was awarded the Federal Cross of Merit, First Class, while the University of Stuttgart conferred an honorary doctorate on him on 26 April 1966.

Pulling away with ease on ice and snow

When starting off in wintry conditions, certain road surface conditions are automatically detected and the interventions of the 4ETS electronic traction control system adjusted so as to achieve the greatest possible acceleration while minimising wheel slip, ensuring optimum directional stability in the process. This strategy also allows the vehicle to pull away under the most adverse conditions, such as when one side of the vehicle is on an icy slope (µ-split) or both wheels on the front or rear axle have limited grip (µ-jump).

When starting off on µ-split, one side of the E-Class 4MATIC is on snow or ice and the other on asphalt. This means there are major differences in the coefficient of friction between the left and right-hand side of the vehicle. On all vehicles with open axle differentials, the wheel with the smallest friction coefficient limits the maximum transferable drive power. If the drive power exceeds the maximum transferable power, the wheels on snow or ice will start to spin and the E-Class 4MATIC would be unable to start off. 4ETS instantly detects this situation and prevents the wheels from spinning by building up exactly the right amount of pressure in the wheel brakes. As the wheel with the higher friction coefficient is now braced by the brake force at the wheel with the smaller friction coefficient, the E-Class 4MATIC starts to move. After pulling away, the wheel characteristics are closely observed and the brake pressure regulated in such a way that, as far as possible, there is no difference in speed between the individual wheels. The braking force applied by 4ETS effectively simulates a higher coefficient of friction on the side of the road covered with ice or snow; ideally, this will match the coefficient of friction on the asphalt side. This produces an optimal inter-wheel locking effect at the axle differentials, resulting in the maximum possible acceleration on µ-split surfaces.

Starting off on “µ-jump” surfaces – where one of the E-Class 4MATIC’s axles is entirely on ice or snow and the other on asphalt – is hampered by the large differences in friction coefficient between the front and rear wheels. On vehicles with an open inter-axle differential, the axle with the lower coefficient of friction determines the transferable drive power. Whilst the multi-disc differential lock with its basic locking torque of 50 Newton metres does have a balancing effect, it is unable to compensate for these extreme differences in friction coefficient. Here again, both wheels on the axle with the lower coefficient of friction start to spin if the drive power exceeds the maximum transferable drive power at this friction coefficient. The 4ETS resolves this problem by instantly detecting spinning wheels and braking them. In this way, the braked axle with the smaller friction coefficient braces the axle with the higher friction coefficient – and the E-Class 4MATIC starts to move.

Assured handling on wintry roads

On twisting roads covered with snow and ice, vehicle stability is primarily controlled by the 4ETS system’s acceleration skid control function regulating engine torque. The 4ETS control thresholds are adjusted according to the driving situation based on the vehicle’s longitudinal and lateral dynamic readings as continuously measured by the ESP® sensor system. The system’s configuration corresponds to the aforementioned Kamm’s circle. To prevent the E-Class 4MATIC from tail-skidding, the longitudinal force when cornering must be controlled by means of engine torque regulation in such a way that there are sufficient reserves of lateral force at all times. In order to comply with this physical correlation, when cornering on road surfaces with a low friction coefficient vehicle stability is mainly controlled by the ESP® and ASR acceleration skid control systems intervening to ensure that there is always sufficient lateral force in reserve. Initially, only enough engine torque to allow the tyres to develop sufficient lateral force is transmitted to the wheels on the outside of the bend. If the ASR control function cannot restore directional stability, the ESP® system will intervene by applying the brakes to stabilise the vehicle.

[adsense]In contrast to the control mechanisms triggered when cornering, considerably more longitudinal force can be provided when accelerating in a straight line, as the tyres hardly have to transfer any lateral force. What is important here is that the tyres can work in the optimum µ-slip curve range. In order to achieve this, the control thresholds for engine torque regulation are raised in this driving situation. When driving on snow-covered or icy roads with low friction coefficients, the multi-disc differential lock in the transfer case takes effect, producing an inter-axle locking torque of 50 Newton metres in the powertrain. This locking effect boosts traction considerably without having any negative impact on the control systems. When the final-drive ratios are factored in, this allows 150 Newton metres to be delivered to the wheels.

In certain wintry conditions it may become necessary to deactivate the control systems using the “ESP® OFF” switch. This is the case where high slip values are required at the wheels – when powering out of deep snow, for instance, either with or without snow chains. Even in “ESP OFF” mode drivers still have the full support of the control systems at their disposal when braking. Once back on a road surface with a normal covering of snow, the control systems should be reactivated again.

High pulling power, low fuel consumption: E-Class 4MATIC: choice of five models

Mercedes-Benz is offering the latest generation of the 4MATIC all-wheel-drive system for the E‑Class, which is even more efficient, even lighter and even more compact than the all-wheel-drive technology fitted previously. These advantages over the outgoing model translate into superior traction and fuel economy. Fuel consumption, for instance, is a mere between 0.2 and 0.6 litres more per hundred kilometres than on a comparable model with conventional drive.

There are five models in the E-Class 4MATIC range:

| E 350 CDI 4MATIC BlueEFFICIENCY | E 350 4MATIC | E 500 4MATIC | |||

| Body | Saloon | Estate | Saloon | Estate | Saloon |

| Engine/cylinders | Diesel/V6 | Petrol/V6 | Petrol/V8 | ||

| Transmission | 7-speed automatic | 7-speed automatic | 7-speed automatic | ||

| Displacement | 2987 cc | 3498 cc | 5461 cc | ||

| Rated output | 170 kW/231 hp | 200 kW/272 hp | 285 kW/388 hp | ||

| Rated torque | 540 Nm at 1600-2400 rpm | 350 Nm at 2400-5000 rpm | 530 Nm at 2800-4800 rpm | ||

| Fuel consumption (l/100 km)* | 7.0 | 7.6 | 9.6 | 10.2 | 11.0 |

| CO2 emissions** (g/km) | 183 | 200 | 226 | 238 | 258 |

| Emissions standard | EU 5 | EU 5 | EU 5 | ||

* NEDC combined fuel consumption; ** on the NEDC driving cycle

The latest-generation 4MATIC only adds 50 to 70 kilograms of extra weight (depending on model) and boasts a compact design that now takes up less space. As a result, no modifications to the bodyshell are required and it does not encroach on the front-passenger footwell. What’s more, the compact design helps to improve noise and vibration levels.

Transfer case integrated in 7G-TRONIC automatic transmission

The 4MATIC transfer case, featuring a planetary centre differential and a pair

of bevel gears acting as a lateral output to the front axle, is integrated into the standard-specification 7G-TRONIC automatic transmission. The centre differential produces the 45:55 torque split between the front and rear axles that has the aforementioned positive impact on handling stability and traction. Further highlights of the powertrain include the lateral output to the front axle as well as the rear universal joint that is integrated into the power take-off’s output gear. This space-optimised design enables the front axle propshaft to be run very close to the transmission without having to modify the bodyshell in any way.

The higher efficiency of the 4MATIC drive system compared to the predecessor models is largely down to the omission of the gear stage for the transfer case’s power take-off as well as an improved oil supply, since the integral design means that transmission and transfer case share the same oil circuit. This sophisticated 4MATIC technology together with the weight saving result in a substantial reduction in fuel consumption.

ADAPTIVE BRAKE: state-of-the-art brake control system ensures shortest stopping distances – even in wintry road conditions

The ADAPTIVE BRAKE control system incorporates the basic anti-lock braking system (ABS), acceleration skid control (ASR) and yaw control functions. ABS and ASR record and control the driving dynamics along the vehicle’s longitudinal axis, while the yaw control looks after the lateral dynamics. If ADAPTIVE BRAKE diagnoses critical driving situations, precision application of the brakes and control of drive torque is used to maintain or restore traction and directional stability as far as is physically possible.

New additional braking functions make the ADAPTIVE BRAKE system even safer and more convenient. Hill-Start Assist prevents the vehicle from rolling in the opposite direction to that intended by the driver. The set of functions also includes brake priming: should the driver suddenly release the accelerator, the system prepares for possible panic braking by pressing the brake pads lightly against the brake discs. If the brakes are indeed applied with full force, the instantaneous build-up of pressure when the brake pedal is pressed shortens the stopping distance by a significant amount. Thanks to ADAPTIVE BRAKE’s ability to produce even the smallest brake pressures with great precision, it is possible to remove the film of water which forms on the brake discs in wet conditions by gently applying the brakes for a brief time. This shortens the brakes’ response time when driving in the wet, thus reducing the stopping distance even further. This function is triggered automatically once a certain number of windscreen wiper cycles has been reached and the driver has not applied the brakes in the meantime.

The E-Class also comes with standard-fit adaptive brake lights. This system alerts the traffic behind to emergency braking by causing the brake lights to flash at high vehicle deceleration rates and, in the case of an emergency stop from a speed of over 70 km/h, automatically switching on the hazard warning lights once the vehicle comes to a halt.

As well as a tyre pressure loss warning system, the Electronic Stability Program (ESP®) also includes a vehicle/trailer stabilisation function as standard, which can defuse critical handling situations when towing a trailer at an incipient stage by applying the brakes as required. The permitted towing capacity is 2100 kilograms (braked).

Mercedes-Benz boasts over a century of experience with all-wheel drive

There is a reason why Mercedes engineers are so skilled in the development

of groundbreaking all-wheel-drive concepts. The history of all-wheel drive at Mercedes-Benz dates all the way back to 1903, when Paul Daimler, the son of the company’s founder, established the basic principles for constructing vehicles with all-wheel drive. Since then, the accepted maxim has been that all-wheel drive is the best technology for making quicker and safer progress under the most adverse conditions. Over the course of the years it has been successfully employed in a variety of Mercedes-Benz models, including both passenger cars and commercial vehicles. Some models, such as the G-Class and the Unimog, have attained legendary status all over the world. But all-wheel drive has its benefits in everyday operation on asphalt roads too, as demonstrated by the 4MATIC saloons from Mercedes-Benz. The innovative drive concept received its saloon premiere in the W 124 E-Class model series back in 1987. The 4ETS system made its debut aboard the M-Class in 1997, although development started back in 1993. Mercedes-Benz has therefore amassed a wealth of experience with these electronic control systems – more in fact than any other car manufacturer.

Bestseller: the E-Class from Mercedes-Benz – Outstanding safety and luxurious comfort combined with top cost efficiency

Fuel consumption is kept low by efficient engines and – on the E 350 CDI 4MATIC – the BlueEFFICIENCY package. Parts and components have been optimised in order to improve energy management as a whole, thereby helping to save fuel. The work done in the wind tunnel was particularly fruitful, as the resulting drag coefficient of just 0.25 makes the E-Class Saloon the world’s most aerodynamically efficient luxury car. It betters the already impressive cd figure of its predecessor by another four percent, which in practice represents a fuel saving of around 0.25 litres per 100 kilometres when driving at a motorway speed of 130 km/h. Further BlueEFFICIENCY measures include newly developed tyres with up to 17 percent lower rolling resistance, as well as the energy-saving control of the alternator, fuel pump, air-conditioning compressor and power steering.

The Mercedes-Benz E-Class – the epitome of ride comfort

Mercedes-Benz achieves the standard of ride comfort which all versions of the E‑Class are renowned for courtesy of the highly sophisticated DIRECT CONTROL suspension with adaptive shock absorbers, an intelligent body design with excellent rigidity, plus enhanced seats which are also available with massage and climate control functions.

The suspension automatically adapts to the changing driving situation by reducing the damping forces during normal driving to substantially improve ride comfort. When taking bends at speed or during rapid evasive manoeuvres, however, the system switches to the maximum damping force so that the saloon is stabilised to best effect. A lowered suspension with dynamic damping characteristics is available as an alternative to the comfort-oriented standard suspension. Mercedes-Benz is the only manufacturer in the world to combine the air suspension system optionally available for all 4MATIC models (standard on the E 500 4MATIC) with a three-link front axle design and a continuously variable, electronically controlled damping system, which processes a series of sensor signals and controls each wheel individually. So, not only do Mercedes customers experience the best in ride comfort, they reap the benefits of excellent handling safety and sporty agility too. The driver can switch between Comfort and Sport mode at the push of a button.

Snug warmth: E-Class offers the heating output of a family home

Carefully balanced control of the interior climate is especially important in the

winter. This is why Mercedes-Benz offers THERMOTRONIC luxury automatic climate control for the E-Class. Apart from regulating the climate separately for the driver, front passenger and passengers in the rear, this system allows individual pre-settings to be programmed too. If the optional multi-zone THERMOTRONIC system is specified, the occupants are able to select “Diffuse”, “Medium” or “Focus” modes at the touch of a button, and so adapt the airflow rate and air distribution to their personal preferences whilst still benefiting from the system’s automatic control functionality. This system furthermore includes a pollutant sensor which automatically switches to air recirculation mode if it detects any sudden increase in the carbon monoxide or nitrogen oxide levels in the outside air – when driving through a tunnel, for instance.

Another highlight of the THERMOTRONIC system is the residual heat function: pressing the “Rest” button heats or ventilates the passenger compartment for around 30 minutes when the engine is switched off. The E-Class is equipped as standard with THERMATIC, a two-zone automatic climate control system. Here, the interior air is kept clean by a large, hermetically sealed fine-particle com-bination filter which is 96 to 98 percent effective. Thanks to the activated-charcoal coating, gaseous substances can also be filtered out by the fine-particle combination filter.

THERMATIC and THERMOTRONIC heat up the passenger compartment of the E‑Class extremely efficiently, even after a cold start on winter mornings. This is thanks to a heating output of eleven kilowatts, equivalent to the capacity of the central heating system in a modern family home. On the diesel models, a heat exchanger with six integral PTC heating elements (PTC = Positive Temperature Coefficient) is also activated when the outside temperature falls below a certain level in order to boost the effect of the main heat exchanger with an electrical output of around 1200 watts. The assistance from the PTC heater is necessary due to the high thermal efficiency of today’s CDI engines, which is precisely what makes them so economical and means that they dissipate considerably less heat to the coolant under partial load conditions than conventional engines.

Safety: nine airbags as standard, plus innovative driver assistance systems

The E-Class is proof that Mercedes-Benz leads the way when it comes to safety. Around a dozen driver assistance systems are on hand to help prevent traffic

accidents or at least reduce the severity of the impact. These include the standard ATTENTION ASSIST drowsiness detection system, as well as the optional DISTRONIC PLUS proximity control and PRE-SAFE® Brake, which is able to initiate partial and emergency braking autonomously. For the first time, PRE-SAFE® is also able to use only the information received from the short-range radar sensors in the front bumper to tension the front seat belts at the last moment before an inevitable collision, thereby reducing the strain exerted on the driver and front passenger in the impact. Plus, on models with fully power-adjustable seats (optional extra), the front passenger seat is adjusted into an optimum position too.

With nine airbags fitted as standard, not to mention four seat belt tensioners and belt force limiters as well as NECK-PRO crash-responsive head restraints for the driver and front passenger, the new E-Class offers an even more extensive safety specification than its predecessor. The airbags, which can deploy in a matter of milliseconds in the event of an accident, include two adaptive airbags for the driver and front passenger, a kneebag for the driver, two sidebags in the front-seat backrests and two large windowbags, which extend from the A-pillar to the C-pillar during a side impact. Pelvisbags for the front-seat occupants are also included for the first time. These reduce the loads acting in the pelvic area in particular during a side-on collision, as well as resulting in favourable occupant kinematics in such impacts. Sidebags are also available for the passengers in the rear as an optional extra. As a further safety innovation, Mercedes-Benz is also offering optional, self-adaptive belt force limiters in the rear for the first time. These are able to automatically adjust to the occupants’ size and weight.

E-Class Estate: exemplary load compartment management

The Estate model comes with the ideal credentials for handling all manner of transport jobs. Not only can as many as seven passengers be seated in comfort with ample amounts of space, the luggage compartment also benefits from the growth in the model’s dimensions. The luggage capacity of 695 litres with the normal seating arrangement can be increased to a vast 1950 litres by folding the rear backrests flat and loading up to roof height. A new best figure not just for this segment, but for the estate market as a whole. Mercedes-Benz’s expertise in the design of estate cars is evident not just from the cavernous load capacity, but also from the top figures in other criteria which are important for everyday practicality, such as the load sill height (56.6 cm) or the through-loading length behind the front seats (over two metres). All Estate models include a self-levelling rear suspension for even greater handling safety as standard.

[adsense]Extending the load compartment is perfectly straightforward thanks to the

standard-fit “Quickfold” system, which means that the rear backrest simply has to be folded onto the seat cushion to produce a flat load floor. For supreme convenience, the backrest can be released and folded down either from the side or from the luggage compartment. The rear backrest’s standard asymmetric split (1/3:2/3) furthermore allows the load space to be increased on just one side. Exemplary load management comes built in too: take, for example, the electromechanically operated EASY-PACK tailgate or the EASY-PACK folding load compartment floor, which can be folded upright and locked into various positions. The EASY-PACK load compartment cover also forms part of the standard specification. The extended cover can be hooked into electrically powered carriers on the D‑pillars – when the tailgate is opened, the load compartment cover is automatically raised for unhindered loading and unloading.