The new generation CL-Class – New engines in the S-Class

Highest levels of refinement: the large Mercedes-Benz luxury saloons and coupés

With the new generation of the CL and new engines for the S-Class, Mercedes-Benz once again raises the standard for efficiency and exclusivity in the luxury saloon and coupé segment. The CL and S-Class come with highly efficient engines with direct petrol injection whose output has been increased by as much as 12.5 percent and whose petrol consumption has been reduced by as much as 24 percent.

The new S 350 BlueEFFICIENCY with V6 engine, for example, is content with just 7.6 litres of premium petrol per 100 kilometres in the New European Driving Cycle (NEDC). That corresponds to CO2 emissions of 177 g/km (previous model 10.0 l/100 km, 234 g/km CO2). In the new versions S 500 BlueEFFICIENCY and CL 500 BlueEFFICIENCY, the combined fuel consumption declined to 9.4 and 9.5 litres per 100 kilometres respectively; that is equivalent to 219 and 224 g/km CO2.

Crucial to this enhanced efficiency is the newly developed BlueDIRECT technology with third-generation spray-guided direct petrol injection in combination with the standard-fit start/stop function and the new 7G-TRONIC PLUS seven-speed automatic transmission. Innovations like the Active Blind Spot Assist and Active Lane Keeping Assist ensure that the CL and S-Class remain the yardstick for automotive progress also in the area of active safety.

The innovative V6 and V8 power plants for the luxury saloons and coupés from Mercedes-Benz establish a modular petrol engine family designed for utmost flexibility. Depending on configuration, both engines operate with or without turbocharger and can be combined with 4MATIC all-wheel drive and hybrid modules.

As first new eight-cylinder engine Mercedes-Benz presents the 4.6-litre twin-biturbo unit that does service in the S 500 BlueEFFICIENCY and the CL 500 BlueEFFICIENCY. The new 3.5-litre V6 starts as a naturally aspirated variant in the S 350 BlueEFFICIENCY. The new Mercedes-Benz engines equally impress with significantly reduced consumption and emissions, but higher power.

Besides the third-generation spray-guided direct petrol injection featuring multiple injection, multi-spark ignition and piezo injectors, the standard-fit ECO start/stop function and the friction-optimised 7G-TRONIC PLUS seven-speed automatic transmission featuring new torque converter technology contribute to this result.

S 350 BlueEFFICIENCY: the most economical petrol model in the luxury class

Compared with the previous power plant with the same displacement, the output of the new V6 petrol engine of the S 350 BlueEFFICIENCY has increased by 12.5 percent from 200 kW (272 hp) to 225 kW (306 hp). The torque has increased by 5.7 percent from 350 to 370 Newton metres. Parallel to the increase in output, consumption has been reduced by 24 percent from 10.0 litres of premium petrol per 100 kilometres to 7.6 litres per 100 kilometres. This makes the S 350 BlueEFFICIENCY the most economical petrol-powered model of the luxury class.

The CO2 emissions likewise have declined by 24 percent from 234 grams per kilometre to 177 grams per kilometre.

New V8 biturbo engine for CL and S-Class with great potential for savings

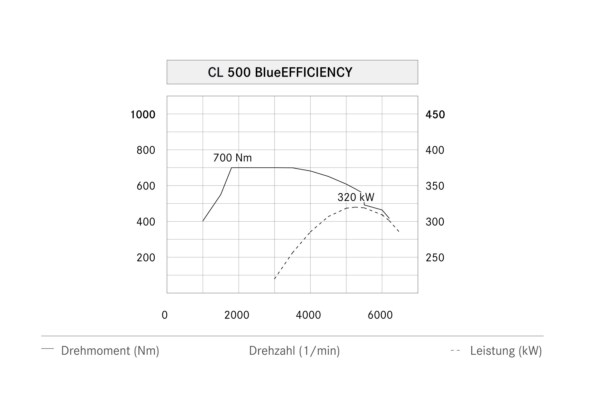

The new V8 biturbo engine in the S 500 BlueEFFICIENCY and CL 500 BlueEFFICIENCY, with its 4663 cubic centimetres displacement, produces 320 kW (435 hp) so that despite 0.8 litres less displacement, it is still around

12 percent more powerful than its predecessor, which had an output of 285 kW (388 hp). At the same time, torque was raised from 530 Nm to an impressive 700 Nm – an increase of 32 percent. Combined consumption in the New European Driving Cycle (NEDC), on the other hand, drops by around 22 percent in the CL 500 BlueEFFICIENCY to 9.5 litres of premium petrol per 100 kilometres. CO2 emissions sink from 288 to 224 grams per kilometre.

The fuel consumption of the S 500 BlueEFFICIENCY is 9.4 litres of premium petrol per 100 kilometres, 15.5 percent (short wheelbase) and 16 percent (long wheelbase) better than that of the previous model. An outstanding value in this output category, it equates to CO2 emissions of 219 grams per kilometre.

S 350 BlueTEC: most fuel-efficient S-Class of all time

The series of highly efficient Mercedes-Benz internal combustion engines is made complete by the new 3.0-litre diesel of the S 350 BlueTEC.

The combined fuel consumption is only 6.8 litres of diesel fuel per 100 kilometres – eleven percent less than in the previous model. That equates to CO2 emissions of 177 grams per kilometre. The S 350 BlueTEC is thus the most fuel-efficient S-Class of all time. Thanks to AdBlue® emission control as standard, the 190 kW (258 hp) S 350 BlueTEC additionally ranks among the world’s cleanest diesel models.

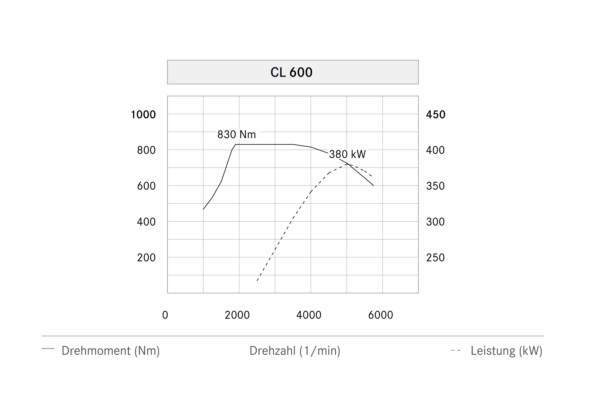

The 380 kW (517 hp) 12-cylinder biturbo engine in the CL 600 and S 600 remains the most powerful engine for the CL and the S-Class and now also complies with the Euro 5 emissions control standard.

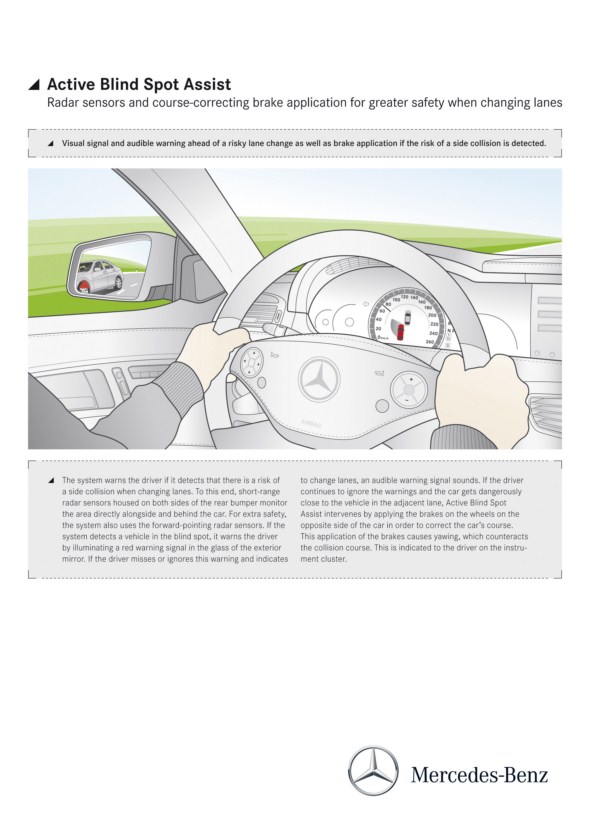

New: Active Lane Keeping Assist and Active Blind Spot Assist

Innovations like the Active Blind Spot Assist and Active Lane Keeping Assist ensure that CL and S-Class remain the yardstick for automotive progress also in the area of safety. The Active Lane Keeping Assist springs into action when the vehicle inadvertently crosses a solid line to the right or left of its lane or a solid line on the outer side of a bend. In this case the Electronic Stability Program ESP® brakes the wheels on the opposite side of the vehicle to prevent unintentional swerving out of the lane.

Also new is the Active Blind Spot Assist, which warns the driver by displaying a red warning in the glass of the relevant exterior mirror when it detects that changing lanes would be too dangerous. If the driver ignores the warnings and comes dangerously close to a vehicle in the neighbouring lane, a novel feature of the system acts: a corrective braking intervention via ESP® on the wheels of the opposite side of the vehicle.

Advanced radar- and camera-based assistance systems

Like the S-Class the new generation of the CL additionally gets the Adaptive Highbeam Assist. Moreover, Mercedes-Benz now also offers Night View Assist Plus for the luxury coupé with a special infrared camera for pedestrian detection. The images supplied by the windscreen camera are also used by the new, optional Speed Limit Assist, which recognises speed limit signs in passing and shows the relevant speed limit in the central display and on the navigation system’s map display (standard for the CL 600).

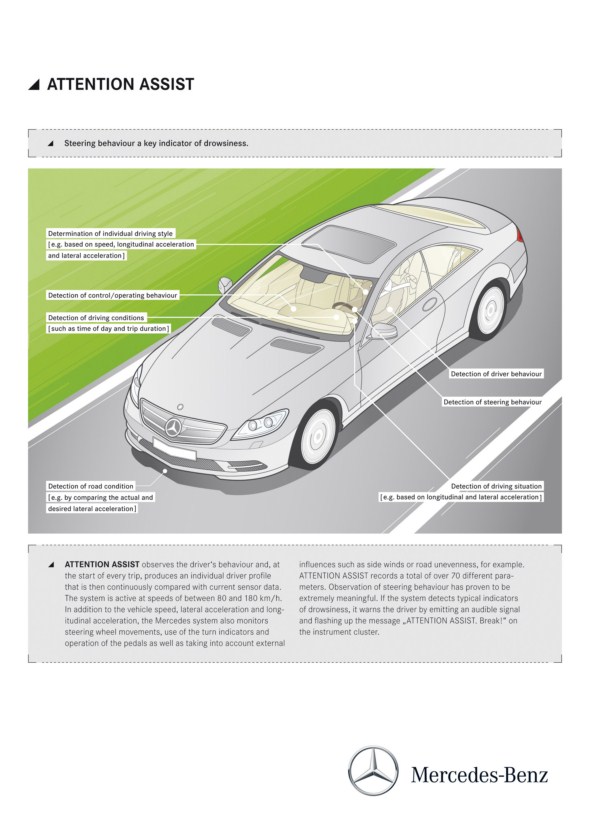

Mercedes-Benz has also improved the long and medium-range radar used by the Brake Assist System PLUS (BAS) PLUS and the DISTRONIC PLUS proximity control in the CL. From the S-Class the large Mercedes coupé also gets the ATTENTION ASSIST drowsiness detector.

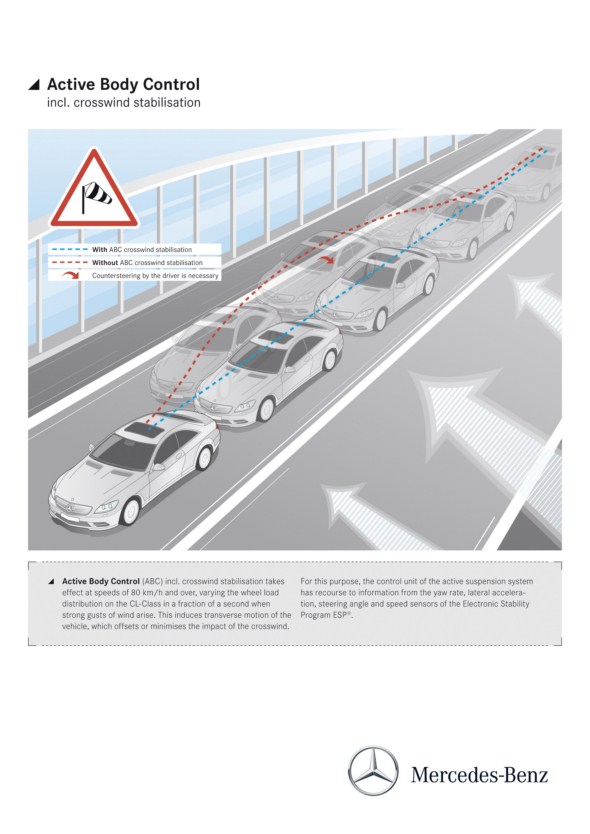

Handling dynamics and active driving safety are further improved by the Direct-Steer system, with variable ratio depending on steering angle, and the modified active suspension Active Body Control (ABC) with crosswind stabilisation. Like the Torque Vectoring Brake – targeted, one-sided braking intervention at the inside rear wheel when cornering, which enables the car to turn into the bend with even greater agility – both features also are familiar from the S-Class.

First-rate onboard infotainment

In line with its serene character and claim to be a technological masterwork, the Mercedes-Benz luxury class also sets standards where onboard infotainment is concerned. From the S-Class the CL gets the optional SPLITVIEW technology for the operating and display systems COMAND und COMAND APS (standard for the CL 600). This is complemented by the Navigation package (standard for the CL 600) with hard-disc navigation (40 gigabytes), 7.2 gigabyte hard disc for storing around 2500 digital music files, Gracenote® database and Music Search function. The latest LINGUATRONIC voice-operated control system rounds off

the high-grade package.

The surround sound system with Discrete Logic7® technology and 14 high-performance loudspeakers, developed by Mercedes-Benz together with the audio specialists Harman Kardon®, creates an outstanding sound experience in the CL (standard for the CL 600).

The new Bang & Olufsen BeoSound AMG sound system tailored to the luxury saloon’s interior is available as a further new feature for the S-Class. A combination of 15 loudspeakers and two amplifiers with a total output of 1200 W ensures a thrilling quality of sound from this high-end system. The algorithm of the digital sound processor allows a choice between high-end studio sound and surround sound, and the audio output can be focused exactly on the front seat positions, the rear seats or the centre of the interior.

Fine materials and first-class finish

In the interior too the Mercedes-Benz developers and designers have perfected the new-generation CL and S-Class with great attention to detail, emphasising the exclusive character of the two model series. In the CL the buyer can choose between four different types of wood, two different leather qualities and five tasteful colour combinations.

A special highlight of this luxury coupé, which is built with a high proportion of hand-finished work: the seats of the flagship model CL 600 are covered with particularly supple PASSION leather with a special V12 fluting design. The fine leather also is used for the upper and lower sections of the dashboard, the interior door trim, parcel shelf, and the ruffled pockets on the backs of the front seats. The trim of the roof liner and the interior trim of the A and C-pillars are clothed in Alcantara leather.

Together with the unique AMG SPEEDSHIFT MCT 7-speed sports transmission, the new AMG 5.5-litre V8 biturbo engine will play a significant role in the Mercedes-AMG model strategy over the coming year. The new engine / transmission combination marks a further milestone in the successful history of Mercedes-AMG, which began back in 1967.

The highlights of the AMG V8-biturbo engine and the AMG SPEEDSHIFT MCT 7-speed sports transmission

• Direct petrol injection with piezo-electric injectors and spray-guided combustion

• Biturbocharging with air/water intercooling

• Sophisticated engine electronics with Controlled Efficiency start/stop function and generator management

• Aluminium crankcase with ventilation holes to reduce friction

• Continuous camshaft adjustment on the intake and exhaust sides

• Demand-controlled engine oil pump

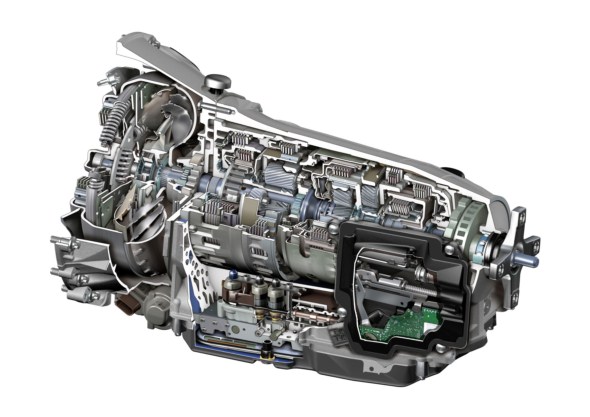

• AMG SPEEDSHIFT MCT 7-speed sports transmission with compact start-up clutch and three drive modes

Engine technology: development goals and design

Perfect combination of performance and efficiency

Emotional peak performance and enormous torque, agile power delivery and a characteristic engine sound, comfort on long journeys and hallmark Mercedes reliability: expectations are high when Mercedes-AMG introduces a new high-performance engine – and its first eight-cylinder biturbo unit is no exception. Two criteria are inexorably gaining in importance, namely efficiency and economy. Mercedes-AMG is confronting the challenges of the future, and demonstrating that exciting dynamic performance can be perfectly combined with fuel economy.

The new AMG 5.5-litre biturbo engine for the S 63 AMG and CL 63 AMG combines performance with efficiency to a previously unknown extent. This is made possible by a unique combination of innovative high-tech systems such as direct petrol injection, biturbocharging, air/water intercooling and the Controlled Efficiency start/stop function.

Mercedes-AMG is systematically following the trend towards increasing efficiency with its new V8 biturbo engine: with a displacement of 5461 cubic centimetres it is precisely 747 cc below the 6208 cc of the naturally aspirated AMG 6.3-litre V8. Nonetheless it considerably betters it in terms of output and torque. It develops a peak output of 400 kW (544 hp) and maximum torque of 800 Nm.

In conjunction with the AMG Performance Package these figures increase to 420 kW (571 hp) and 900 Nm. The torque curve in particular shows that no other engine in this output class is able to match the figures delivered by the new AMG biturbo unit.

Despite an increase in output of 14 kW (19 hp) and 34 kW (46 hp) respectively, and in torque of 170 and 270 Nm compared to the naturally aspirated V8, which develops 386 kW (525 hp) and 630 Nm, AMG engineers have been able to reduce fuel consumption and CO2 emissions considerably.

With an NEDC fuel consumption of only 10.5 litres per 100 kilometres, the S 63 AMG and CL 63 AMG better their predecessors by 3.9 litres. This equates to a fuel saving of more than 25 percent, which engine specialists consider to be nothing less than a quantum leap. CO2 emissions have likewise been significantly reduced: at 244 grams per kilometre, the figure is almost 30 percent lower than for the previous model (344 g/km). Page 13

The achievement of these efficiency and environmental aims has no negative effects whatsoever on dynamic performance. On the contrary, as the new AMG 5.5–litre V8 biturbo fully lives up to AMG’s brand commitment to “performance”: the S 63 AMG and CL 63 AMG accelerate from zero to 100 km/h in 4.5 seconds, and have a top speed of 250 km/h (electronically limited). With the AMG Performance package, both high-performance cars reach the 100 km/h mark in 4.4 seconds and go on to a top speed of 300 km/h (electronically limited).

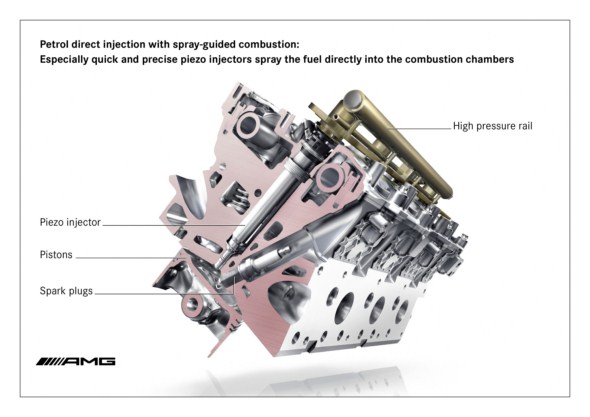

Combination of biturbocharging and direct petrol injection

Mercedes-AMG is presenting an attractive high-tech package with its combination of biturbocharging and direct petrol injection with spray-guided combustion. The innovative injection technology brings decisive advantages with respect to fuel consumption and exhaust emissions, thanks to higher thermodynamic efficiency. Particularly fast and precise piezo-electric injectors spray the fuel directly into the combustion chambers, ensuring a homogenous fuel/air mixture and highly effective combustion.

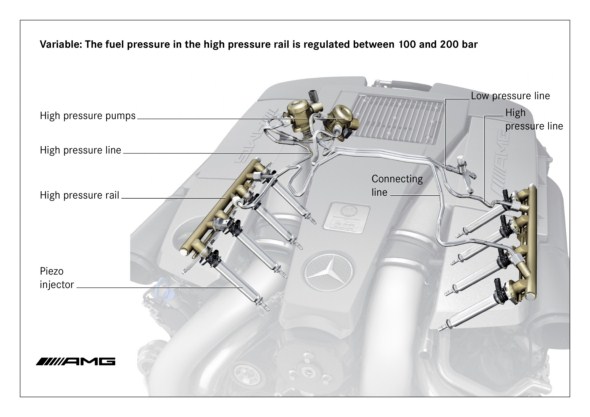

An electric low-pressure pump delivers the fuel from the tank to a high-pressure pump in the boot with a pressure of six bar. The fuel pressure in the high-pressure rail is controlled between 100 and 200 bar on a fully variable and demand-related basis.

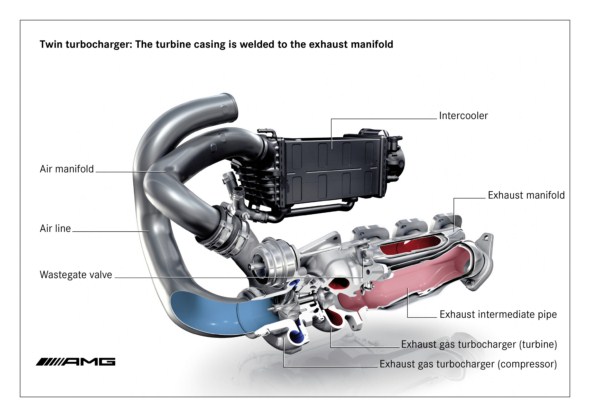

Two exhaust gas turbochargers and efficient air/water intercooling

Two exhaust gas turbochargers located next to the cylinder banks supply the eight cylinders with fresh air. At their maximum speed of 185,000 rpm under full load, the two turbochargers force 1750 kg of air into the combustion chambers per hour.

The maximum charge pressure is 1.0 bar, and 1.3 bar with the AMG Performance package. Thanks to their specific, compact construction – the turbine housings are welded to the exhaust manifold – there are significant space advantages and the catalytic converters also heat up more rapidly.

The new AMG V8 is the first turbocharged engine to dispense with the usual blow-off valve. This neat solution enabled the compressor housing to be made extremely compact. To ensure agile responsiveness with no time lag, all the air ducts in the intake tract are as short as possible. The wastegate valve, which reduces the pressure in the exhaust system during negative load changes, is vacuum-controlled via an electropneumatic converter. This allows dethrottling under partial loads, which in turn lowers the fuel consumption.

As was already the case in the AMG 6.0-litre V12 biturbo engine, the new eight-cylinder direct-injection unit uses particularly efficient air/water intercooling. The low-temperature cooler with its water circulation is space-savingly accommodated within the V of the cylinder banks.

It effectively cools down the intake air compressed by the turbochargers before it enters the combustion chambers, and maintains a constantly low intake temperature under full load. A large radiator at the car’s front end ensures defined cooling of the water circulating in the low-temperature circuit.

This guarantees a high output and torque yield in all ambient temperatures and operating conditions. Extremely short charge air ducting makes for outstanding responsiveness. The stainless steel pressure pipes for the fresh and charge air are produced by the hydroforming process, have a wall thickness of only 0.8 millimetres and are designed for particularly low pressure loss.

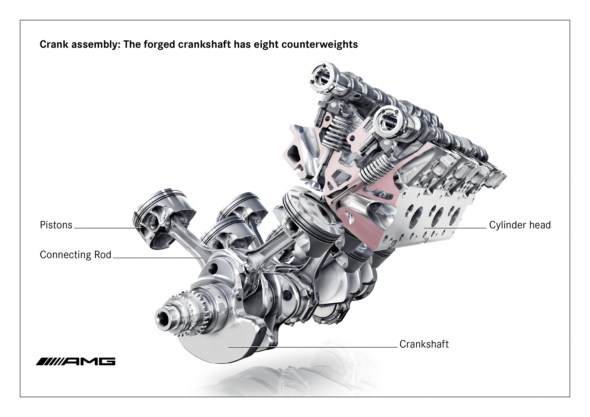

Aluminium crankcase with Silitec cylinder liners

The crankcase of the new AMG 5.5-litre V8 biturbo engine is of diecast aluminium. The low (dry) engine weight of just 204 kilograms is the result of uncompromising lightweight construction methods, and leads to the car’s very balanced weight distribution. The bearing cover for the main crankshaft bearings is of grey cast iron, and is bolted to the crankcase for high rigidity.

Cast-in Silitec cylinder liners ensure that the eight pistons operate with low friction. Drilled pulsation holes in the crankcase lead to a higher output and fuel savings under partial load: above the bearing blocks there are longitudinally drilled holes which connect adjacent crankcase cavities. Normally the upward and downward movement of the pistons causes air to be forced into and extracted from the sump, which leads to increased internal friction losses and therefore a reduction in output. The pulsation holes prevent this by ensuring effective pressure compensation between the cavities.

The forged crankshaft of high-grade 38MnS6BY steel alloy rotates in five main bearings, has eight counterweights and has been optimised with respect to torsional rigidity, inertia, low rotating masses and a long operating life. A two-mass viscous damper mounted at the front reliably eliminates vibrations. Each connecting rod journal on the crankshaft carries two forged, cracked connecting rods. In the interests of low mechanical friction and high wear resistance, the lightweight pistons have a metallic contact surface. Pressure-controlled oil-spray nozzles in the crankcase ensure that the highly stressed piston crowns are efficiently cooled.

Four-valve technology with variable camshaft adjustment

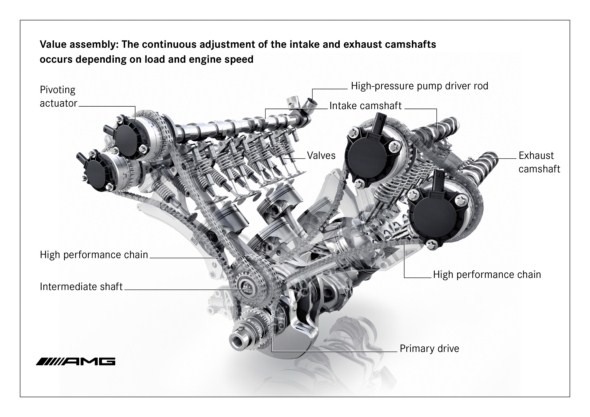

Perfect charging of the combustion chambers is ensured by large intake and exhaust valves, of which there are four per cylinder. The exhaust valves, which are subject to high thermal loads, are hollow and sodium-cooled. Four overhead camshafts operate the 32 valves via low-maintenance, low-friction cam followers. The infinitely variable camshaft adjustment within a range of 40 degrees on the intake and exhaust sides depends on the engine load and engine speed, leading to outstanding output and torque values.

This also results in consistent idling at a low speed. Depending on the engine speed, valve overlap can be varied for the best possible fuel/air supply to the combustion chambers and efficient removal of the exhaust gases. The variable camshaft adjustment is carried out electromagnetically via four pivoting actuators, and is controlled by the engine control unit. The camshafts are driven by three high-performance silent chains, which have considerable advantages in terms of noise comfort compared with cylinder roller chains.

Efficient oil supply and water cooling

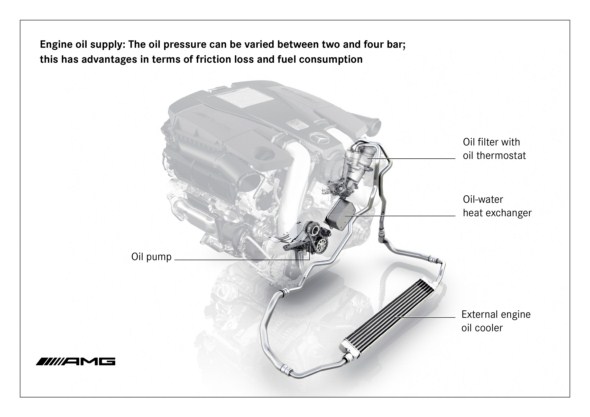

Efficient oil delivery under all load and operating conditions is ensured by an oil pump with an electrically controlled compression stage. The oil pressure can be varied between two and four bar, which has advantages in terms of friction and fuel consumption. An extraction stage integrated into the oil pump for the two turbochargers prevents oil from being entrained into the charge air and exhaust gases, thereby helping to reduce emissions even further. Both the sump and the extraction point have been optimised for maximum lateral acceleration and efficient lubrication. The oil capacity is 10.5 litres.

The combined water/oil cooling system is a particularly clever solution: initially the engine oil only flows through the oil/water heat exchanger. If the cooling performance of the very compact cooler is insufficient, the flow is directed through the external engine oil/air cooler by an oil thermostat. The advantage of this system is that the engine oil warms up more rapidly, as the engine coolant warms up faster and the oil is later cooled by the coolant. A selectable water thermostat ensures rapid warming of the coolant when starting the engine and driving off.

The engine coolant is cooled using the particularly effective crossflow principle. There is a transverse flow of coolant through both the crankcase and the cylinder heads. Additional cooling slots in the cylinder head ensure more efficient cooling of the combustion chambers, which has advantages during combustion: it enables earlier ignition timings to be chosen without incurring the risk of knocking.

Highly efficient engine electronics for every function

All the engine functions are executed and controlled by a particularly efficient Bosch MED 17.7.3. control unit. This state-of-the-art engine computer not only controls the direct petrol injection, charge pressure, camshaft adjustment and variable oil supply, but also communicates with all the other onboard control units. The microprocessor has more than 30,000 differ