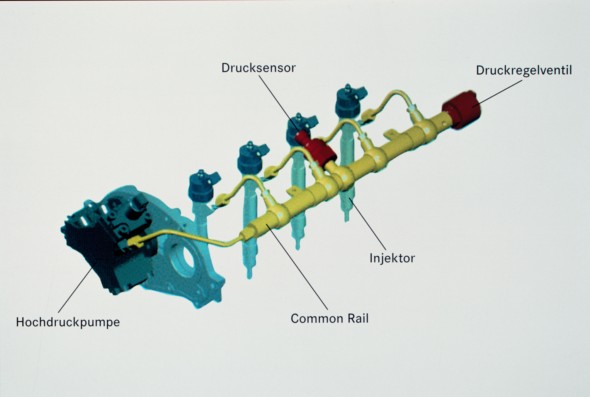

Common Rail

Modern injection system for diesel engines. Diesel fuel is injected under high pressure (ca. 1.350 bar) from a common rail for all cylinders.

Advantage is lower fuel consumption, smoother run and cleaner burning of the fuel. Originally developed by Marelli (FIAT), further developed by Bosch.

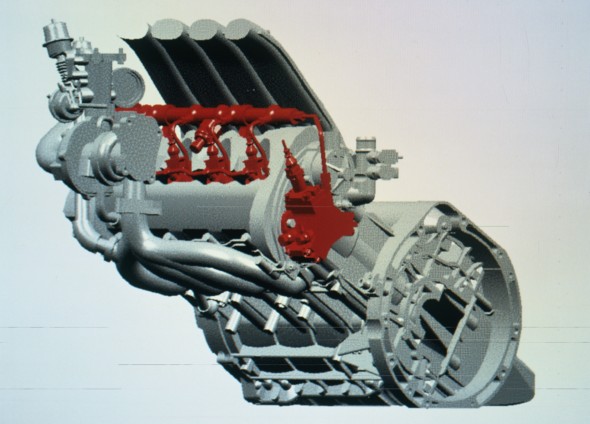

The sophisticated common rail injection system from Mercedes, as featured e.g. in the C-Class (W202, W203), E-Class (W210) and S-Class (W220) CDI variants, represents the ideal compromise between economy, torque, ride comfort and durability.

Whereas conventional direct injection diesel engines need to build up the fuel pressure over and over again for each injection cycle, pressure in the CDI power plant is built up independently of the injection sequence and is constantly available in the fuel line.

The ‘common rail’ which precedes the cylinders serves as a pressure reservoir and distributes the fuel to the injectors at a constant pressure of up to 1600 bar.

Based on the instructions from the electronic engine management unit, high-efficiency solenoid valves in the injectors govern both the injection timing and the quantity of fuel injected for each cylinder combustion chamber individually, in order to match current requirements.

In other words, pressure build-up and fuel injection take place quite independently of one another, which is the key advantage of the common rail system over conventional processes.

Pilot injection in CDI diesel engines can be governed just as flexibly to match current requirements as the main injection stage; a few milliseconds prior to actual injection, a small quantity of diesel fuel flows into the cylinders, ignites and thus preheats the combustion chambers.

This improves conditions for the main injection, which has a positive effect on combustion noise and nitrogen oxide emissions.