Mercedes-Benz S-Class – a pace setter and a fine example of vehicle safety

- Major innovations in vehicle safety shape the history of the Mercedes-Benz S-Class

- Daimler continually sets the standard for the entire vehicle industry with new solutions

Stuttgart – This history of the Mercedes-Benz S-Class is a history of vehicle safety at the highest level. A tradition of outstanding innovations which have debuted in the S-Class have made these premium cars from Stuttgart pioneers for new solutions and a worldwide benchmark in vehicle safety. Thus beyond their own vehicles, Daimler continually establish standards in active, passive and integrated safety for the entire automotive industry.

The examples range from the safety body in the 1959 “tailfin” (model series W 111) to the anti-lock braking system introduced in the S-Class (model series W 116) in 1978, the air bag (1981 premiere in the S-Class W/V 126 model series), and the Mercedes-Benz integral safety concept.

This trend-setting concept was unveiled in 2005 in the S-Class (model series W/V 221) under the name PRO-SAFE™. The integral safety concept also includes the PRE-SAFE® preventive safety system, which was introduced in the S-Class W/V 220 model series in 2002.

Safety in the S-Class as a mirror of its time

Vehicle safety, for many decades after the invention of the car, meant striving for a car which was as stable as possible, with good handling characteristics, based on empirical knowledge gleaned from series production and motor racing. But in the 1950s, the company’s internal research department began stepping up its work on vehicle safety using new scientific methods.

Thus it was during this period that selective crash tests and corresponding driving tests began to be conducted.

It was in the 1950s that mass motorisation became widespread in the West; road traffic was becoming heavier and faster, and accident statistics were on the rise. This prompted urgent, new questions about vehicle safety, and Mercedes-Benz engineers responded with their innovations. This ultimately resulted in solutions for series production vehicles, which often debuted in the saloons of the S-Class.

Thus the top-of-the-range vehicles from Mercedes-Benz again and again became trendsetters for new safety topics. And its history also reflects the way in which the understanding of vehicle safety grew and changed with each era. Starting in the 1960s, procedures such as the digital simulation and calculation of crash performance, amongst others, were developed – highly complex and ground-breaking engineering tools.

The research and experimental vehicles also provide evidence of the importance of the S-Class in safety research. Amongst others the ESF 22 (1973) and ESF 24 (1974) experimental safety vehicles were based on the S-Class saloons in the W 116 model series.

Most recently, an S 400 HYBRID W/V 221 was the basis for the ESF 2009 presented in 2009. And the Stuttgart-based manufacturer’s research vehicles have repeatedly anticipated crucial aspects of safety engineering which have later gone on to debut in the saloons of the S-Class. This continued up to the F 125! from 2011, which provided a visionary view of a possible luxury Saloon in the year 2025.

The discovery of safety

In the 1950s and 1960s, engineers and researchers laid the foundation for critical safety innovations of the coming years. At that time, there was a growing understanding and refinement of the principle of vehicle safety.

For example, a conscious distinction was made between passive and active safety with the appropriate sub-speciality fields of study: whereas active safety with its aspects of driving safety, conditional safety and operational safety had always played an important role for engineers since the invention of the car, the far-reaching significance of passive safety was fully understood in the mid-20th century.

One of the first highlights in series production was the premiere of the safety body in the “tailfin” (W 111) in 1959. The safety body was developed by the mastermind of vehicle safety, Béla Barényi, who had been employed at Daimler-Benz since 1939.

Amongst his most important innovations was the door lock with securing pin, which was first presented in 1951. Many of his ideas were so ahead of their time that some did not make it into series production until long after Barényi had left active service, for example, the recessed windscreen wiper when in standby mode, which was introduced in the W/V 126 model series of the S-Class in 1979.

Barényi’s safety body is based on the concept of a shape-stable passenger cell with specific deformable crumple zones at the front and rear to dissipate kinetic energy in the event of a collision. The “tailfin” premium vehicles thus heralded the first high point of vehicle safety research at Mercedes-Benz, and the safety body soon became the international standard for passive safety in the global car design industry.

Vehicle safety as an integral theme

The aspiration for even greater vehicle safety led to innovations which affected all areas of the car. Amongst other things, the Mercedes-Benz engineers established padded structures in the interior, improved the safety of the body structure with the help of increasingly sophisticated crash tests and optimised the conditional safety with improved ergonomics.

The entire chassis was also further improved in terms of safety. For example, Mercedes-Benz introduced disc brakes on all four wheels in 1961. The dual-circuit braking system followed in 1963.

The company took a decisive step into the future of vehicle safety with the W 116 model series of the S-Class, which had its first public showing in 1972. This premium Saloon was characterised amongst other things by improved crash performance and extreme comfort for optimal conditional safety, plus countless detailed solutions for passive and active safety.

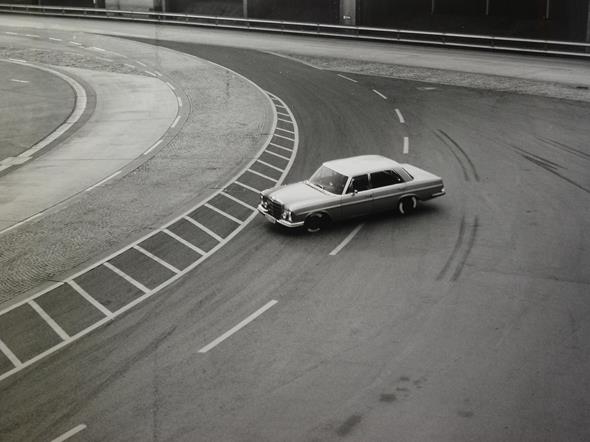

Its front suspension with a zero scrub radius and progressive anti-dive control was an important contribution to active safety, but it also served as the basis for a further epic application: it was in the W 116 model series that the ABS anti-lock braking system made its series debut in 1978.

This system ensured that the vehicle was still able to be steered even when the brakes were fully applied and it also led to the shortening of the braking distance, particularly on wet roads. It took over 20 years for ABS to be developed from the initial idea to series deployment: the first patent for the technology was filed back in 1953 by Dr. Hans Scherenberg, chief developer of the company from 1966 to 1977.

From the air bag to ESP®

Ongoing research makes vehicles safer and safer. But the work of researchers also identifies new spheres of activity. Thus it became clear that an offset collision between two vehicles is especially dangerous and presents particularly difficult challenges for the body structure. In 1979, the S-Class W/V 126 model series was the world’s first passenger car to answer these challenges with its patented forked-beam structure in the front section of the car.

This generation of the S-Class, however, truly set the standard for safety with the unveiling of its driver air bag in 1981. Housed in the impact-absorbing element of the steering wheel, the air bag inflates to a protective cushion within fractions of a second after an accident. The air bag was developed by a research group under the direction of Professor Guntram Huber, who was at the time Director of Development for Passenger Car Bodies. On the heels of the driver air bag came the passenger air bag in 1988 – also in the W/V 126 model series of the S-Class. Today, this basic principle is an integral part of all modern vehicles and is used in various locations.

In 1991, Mercedes-Benz introduced the S-Class W/V 140 model series. A crucial aspect of this car was the improved structural safety of the body to comply with legal requirements for offset frontal collisions with an overlap of 40 per cent or less.

The engineers achieved this in part by developing a tapered longitudinal member at the front end which featured ribs to enable a clearly defined deformation. Moreover, the chassis subframe was elastically connected to the body in such a way that it shifted with respect to the occupant cell as soon as it was subjected to a deformation of medium severity. The car also featured numerous other details, many of which were designed to improve pedestrian protection.

In 1995, the Electronic Stability Program ESP® was introduced to a worldwide audience for the first time in the 140 model series. By selectively applying the brakes on individual wheels while at the same time intervening in the engine management, this Mercedes-Benz innovation prevents the car from skidding in critical driving situations.

ESP® is one of the major inventions for active safety. Beginning with the S-Class, this ground-breaking system found its way into other models and ultimately became the international standard for modern vehicle safety throughout the world.

The S-Class on the road to integral safety

The intelligent link between innovation and the evolution of the safety-related vehicle systems also defines the W/V 220 model series of the S-Class, which had its market launch in 1998. New features included window bags and rear side bags, as well as belt tensioners with force limitation for the two outside seat belts in the rear. In addition, the DISTRONIC adaptive cruise control system as an option to the standard cruise control provided a decisive safety gain.

On the basis of radar signals, the system brakes and accelerates the car such that the S-Class maintains a set safety distance from the vehicle ahead. At speeds between 40 and 160 km/h, the system operates independently of the driver’s interventions.

The Active Body Control (ABC) chassis with an active suspension system was unveiled worldwide in 1999. It mitigates the pitching and rolling motions of the vehicle and increases the safety reserves, and also helps reduce driver fatigue, even on the longest trips – a crucial aspect of conditional safety which is always an object of attention at Mercedes-Benz through the interplay of the various systems.

ABC is part of the standard equipment in the S 600 and is available as an option in all other models of the S-Class.

In 2002, the PRE-SAFE® safety system had its world premiere in the facelifted S-Class of the W/V 220 model series. Based on an idea by the Mercedes-Benz engineer Karl-Heinz Baumann, this system for preventive occupant protection combines elements of both active and passive safety.

The basic principle of PRE-SAFE® is the notion of protecting a vehicle’s occupants with reversible measures before a potential accident occurs. When it was introduced in 2002, PRE-SAFE® initially provided for preventive tightening of the driver’s and front passenger’s seat belts when the sensor system detected a critical driving situation.

At the same time, the front passenger’s seat was moved to a more favourable position via the servomotors, and the sliding sunroof was closed.

PRE-SAFE® was an important milestone for Mercedes-Benz in the development of integral safety. In 2005, the W/V 221 model series of the S-Class showed just how this integral concept influences the design of a vehicle and its systems: PRE-SAFE® was expanded to include a number of new functions, including the adjustment of the head restraints to an optimal position, the closing of the side window, and the inflation of the side bolsters on the multi-contour seats whenever the system detects a critical situation. The S-Class now also responded to panic braking, targeted braking and critical steering manoeuvres.

In 2005, the S-Class definitively became the vehicle which was defined by an integral safety concept. Under the name PRO-SAFE™, the safety engineers grouped the whole range of elements which originated from active and passive safety and which were increasingly merging into a sophisticated system. The company later coined the term “integral safety” for this, bringing us a step closer to the vision of accident-free driving.

Amongst the innovations which were presented as elements of integral safety in the S-Class W/V 221 model series in 2005 were systems such as DISTRONIC PLUS and Night View Assist. DISTRONIC PLUS was available in combination with Brake Assist BAS PLUS.

Adaptive cruise control in the S-Class now operated in a speed range from zero to 200 km/h. Even in stop-start traffic, DISTRONIC PLUS keeps a constant distance from the vehicle ahead and applies the brakes to bring the car to a standstill if needed. In 2007, Blind Spot Assist was put into series production, and the assistance system was upgraded to Active Blind Spot Assist in 2010.

In 2009, the ESF 2009 experimental safety vehicle, developed on basis of the W/V 221 model series, pointed the way to the future of safety in the S-Class. The car featured never-before-seen elements such as inflatable sheet-metal structures to replace the safety elements currently in use and the brake bag. Just before a collision occurs, this air bag inflates beneath the vehicle, doubling the braking performance with its large friction surface.

Daimler is also testing head air bags between the front seats as added side-impact protection and inflatable seat belts to diminish forces acting on the upper body. These are some preliminary glimpses of the systems of the future – perhaps you will see them debut in coming generations of the S-Class.

The shaping force of modern safety engineering

Professor Guntram Huber

Born in Landshut on 20 March 1935

In his work as a design engineer, Guntram Huber devoted his entire professional life to Mercedes-Benz brand vehicles, influencing and fashioning countless safety features up to production launch. Alongside bodies developed according to the latest findings in crash safety, the important milestones of his career include various safety systems, all of which celebrated their world premiere in the Mercedes-Benz S-Class.

Amongst these are the anti-lock braking system (ABS, presented in 1978, model series W 116), the driver air bag (1981, model series W/V 126), the front-passenger air bag (1988, also model series W/V 126) and the ESP® Electronic Stability Program (1995, model series 140).

After completing his education at a secondary school specialising in classical studies, the native of Landshut completed his mechanical engineering studies at the Technical University in Munich to become a graduate engineer. In 1959, he began working for the then Daimler-Benz AG as a test engineer in the Engineering Department for Passenger Car Bodies.

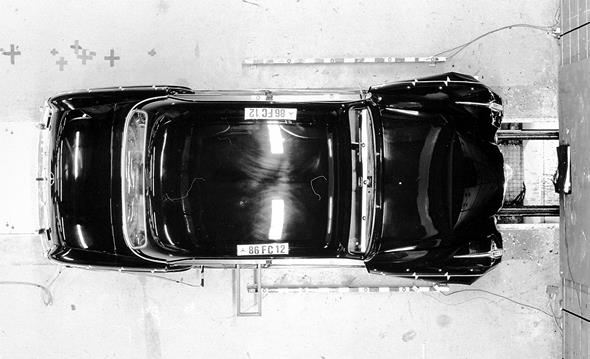

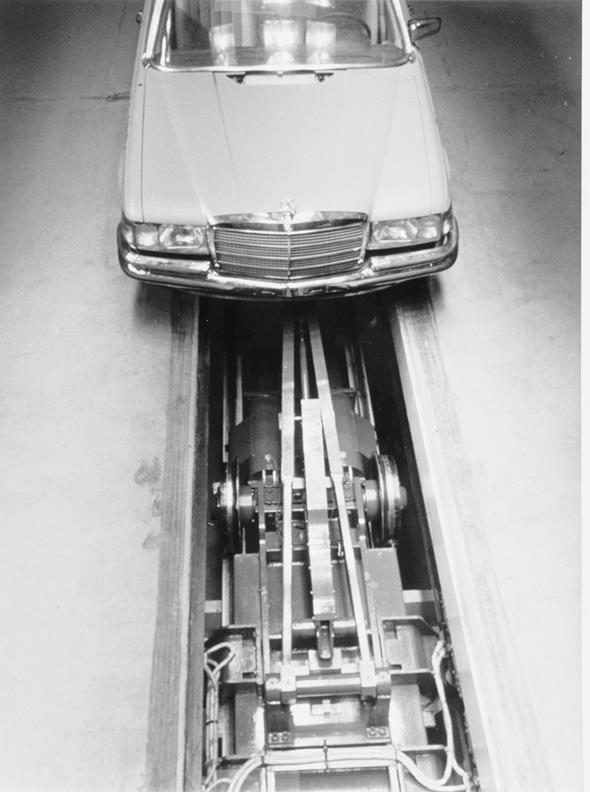

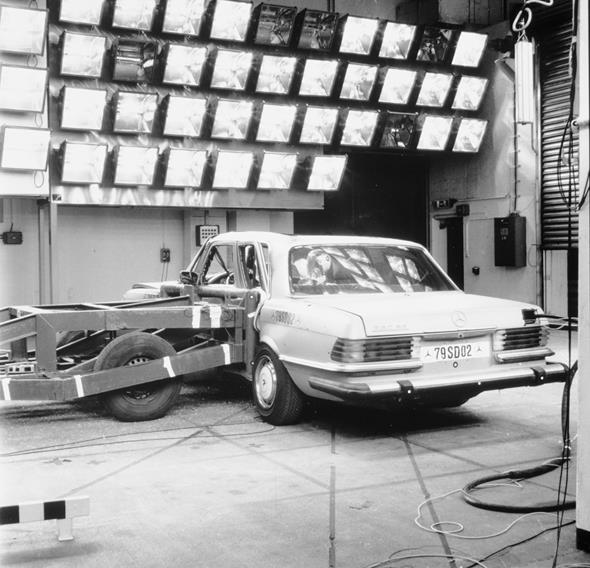

At that time, the Mercedes-Benz “tailfin” (W 111), the world’s first passenger car featuring a safety body, was just about to be launched into series production, but crash tests to verify the basic idea with a shape-stable occupant cell and crumple zones at the front and rear were as yet only in the preparation stages. The young engineer was involved in these tests from the outset.

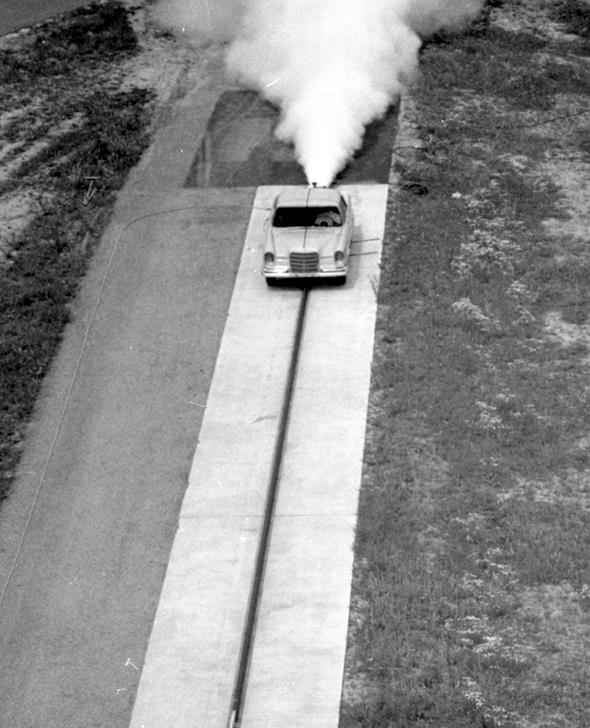

The crash tests first took place outdoors, initially with a hoisting winch and then with a steam rocket as the auxiliary propulsion, and finally in a dedicated crash hall with custom-designed facilities. In March 1977, Huber succeeded Werner Breitschwerdt as Head of Engineering for Passenger Car Bodies and became a constant proponent and promoter of advances in active and passive safety measures.

Numerous safety innovations from Mercedes-Benz have made their debut in S-Class vehicles. A major milestone was ABS, which Mercedes-Benz presented as a world first in the W 116 model series in August 1978. Even at its market launch in 1972, the W 116 attracted much attention with its integral safety concept. In 1979, the S-Class W/V 126, featuring safety aspects developed under the direction of Guntram Huber, had its world premiere – the first passenger car in the world systematically developed to meet the safety requirements for an offset crash.

And on the subject of air bags: in 1981, after 15 years of basic and detailed development, Mercedes-Benz were the first car brand in the world to offer their customers a driver’s air bag in the steering wheel, also in the W/V 126 model series – Huber became known as the “father of the air bag”. The front-passenger air bag followed in 1988, also in the S-Class.

From 1994, in addition to heading up body engineering, Guntram Huber also assumed responsibility for the development of axles, brakes and steering wheels for Mercedes-Benz passenger cars.

That same year, he was awarded a Safety Trophy by the United States Department of Transportation, in recognition of Huber’s service in introducing and implementing the first vehicle safety laws in the U.S. – he had been involved in this enormous undertaking since 1967.

ESP®, first introduced in the S-Class Coupé in 1995 and today an indispensable feature of all vehicle classes, also fell under his area of responsibility and development, as did DISTRONIC adaptive cruise control, a system designed to avoid rear-end collisions with the vehicle in front and minimise the consequences of an accident, also introduced in the S-Class in 1998.

Of equal importance for minimising the consequences of an accident were the air bag advances achieved under Huber, up to and including the sidebag (first introduced in 1995 in the E-Class model series W/S 210) and the window bag (also first introduced in the W/S 210 in July 1998).

But the electronic drive authorisation system KEYLESS-GO and Active Body Control (ABC), aimed at avoiding lateral inclination when cornering, were also developed during Huber’s tenure as director.

In 1981, in addition to his work for Mercedes-Benz, he also accepted a teaching contract on the topic of body engineering as Chair of the Motor-Vehicle Engineering department at Darmstadt Technical University.

In 1987, he was awarded the title of Honorary Professor by the Minister of Science and Art of the State of Hesse. He remained Chair of the department until July 1998 – at that time, he was already retired from his position as a design engineer, a transition he made on 31 December 1997.

Still today, he considers the Mercedes-Benz brand’s greatest service to be that it raised public awareness of the issue of vehicle safety through countless innovations and made it the norm. Indeed, many Mercedes-Benz inventions are now standard equipment in production vehicles across the globe.

The shaping force of modern safety engineering

Professor Guntram Huber

Born in Landshut on 20 March 1935

In his work as a design engineer, Guntram Huber devoted his entire professional life to Mercedes-Benz brand vehicles, influencing and fashioning countless safety features up to production launch. Alongside bodies developed according to the latest findings in crash safety, the important milestones of his career include various safety systems, all of which celebrated their world premiere in the Mercedes-Benz S-Class.

Amongst these are the anti-lock braking system (ABS, presented in 1978, model series W 116), the driver air bag (1981, model series W/V 126), the front-passenger air bag (1988, also model series W/V 126) and the ESP® Electronic Stability Program (1995, model series 140).

After completing his education at a secondary school specialising in classical studies, the native of Landshut completed his mechanical engineering studies at the Technical University in Munich to become a graduate engineer.

In 1959, he began working for the then Daimler-Benz AG as a test engineer in the Engineering Department for Passenger Car Bodies. At that time, the Mercedes-Benz “tailfin” (W 111), the world’s first passenger car featuring a safety body, was just about to be launched into series production, but crash tests to verify the basic idea with a shape-stable occupant cell and crumple zones at the front and rear were as yet only in the preparation stages.

The young engineer was involved in these tests from the outset. The crash tests first took place outdoors, initially with a hoisting winch and then with a steam rocket as the auxiliary propulsion, and finally in a dedicated crash hall with custom-designed facilities. In March 1977, Huber succeeded Werner Breitschwerdt as Head of Engineering for Passenger Car Bodies and became a constant proponent and promoter of advances in active and passive safety measures.

Numerous safety innovations from Mercedes-Benz have made their debut in S-Class vehicles. A major milestone was ABS, which Mercedes-Benz presented as a world first in the W 116 model series in August 1978. Even at its market launch in 1972, the W 116 attracted much attention with its integral safety concept. In 1979, the S-Class W/V 126, featuring safety aspects developed under the direction of Guntram Huber, had its world premiere – the first passenger car in the world systematically developed to meet the safety requirements for an offset crash.

And on the subject of air bags: in 1981, after 15 years of basic and detailed development, Mercedes-Benz were the first car brand in the world to offer their customers a driver’s air bag in the steering wheel, also in the W/V 126 model series – Huber became known as the “father of the air bag”. The front-passenger air bag followed in 1988, also in the S-Class.

From 1994, in addition to heading up body engineering, Guntram Huber also assumed responsibility for the development of axles, brakes and steering wheels for Mercedes-Benz passenger cars.

That same year, he was awarded a Safety Trophy by the United States Department of Transportation, in recognition of Huber’s service in introducing and implementing the first vehicle safety laws in the U.S. – he had been involved in this enormous undertaking since 1967.

ESP®, first introduced in the S-Class Coupé in 1995 and today an indispensable feature of all vehicle classes, also fell under his area of responsibility and development, as did DISTRONIC adaptive cruise control, a system designed to avoid rear-end collisions with the vehicle in front and minimise the consequences of an accident, also introduced in the S-Class in 1998.

Of equal importance for minimising the consequences of an accident were the air bag advances achieved under Huber, up to and including the sidebag (first introduced in 1995 in the E-Class model series W/S 210) and the window bag (also first introduced in the W/S 210 in July 1998).

But the electronic drive authorisation system KEYLESS-GO and Active Body Control (ABC), aimed at avoiding lateral inclination when cornering, were also developed during Huber’s tenure as director.

In 1981, in addition to his work for Mercedes-Benz, he also accepted a teaching contract on the topic of body engineering as Chair of the Motor-Vehicle Engineering department at Darmstadt Technical University.

In 1987, he was awarded the title of Honorary Professor by the Minister of Science and Art of the State of Hesse. He remained Chair of the department until July 1998 – at that time, he was already retired from his position as a design engineer, a transition he made on 31 December 1997.

Still today, he considers the Mercedes-Benz brand’s greatest service to be that it raised public awareness of the issue of vehicle safety through countless innovations and made it the norm. Indeed, many Mercedes-Benz inventions are now standard equipment in production vehicles across the globe.

Technical-physical solutions for a perfect vehicle concept

Frank Knothe

Born in Dresden on 24 February 1942

In his professional career as an engineer, Frank Knothe had a hand in developing numerous Mercedes-Benz passenger car model series. On 1 July 1991, he succeeded the well-known head of testing, Hans Werner (“tall Werner”), as the Head of the Complete Vehicle Testing Department.

With the structural change to individual model series, he became Head of Complete Vehicle Engineering for the S-Class, the SL-Class and the SLK-Class on 1 July 1994. He fulfilled this role until he retired in 2006.

A native of Dresden, Frank Knothe studied at the Technical University in Karlsruhe and completed his studies as a graduate engineer in 1966. That same year, he began working for the then Daimler-Benz AG. His original interest lay in turbomachinery, which included compressors, turbines, and jet engines. The fact that he ended up working with cars despite this would influence his professional path up until the end of his active career.

Knothe first came into contact with direct predecessor vehicles of the S-Class in the late 1960s, during his involvement with chassis development. It was during this period that he encountered the then almost legendary passenger car chief developer Rudolf Uhlenhaut – a boss to whom Knothe attributed great talent in the evaluation of cars and whom he described as a great engineer and one who was completely unassuming in his demeanour.

Work on subsequent generations of the S-Class was always one of Frank Knothe’s key responsibilities, alongside his responsibility for other model series, such as the SL and, starting in the early 1990s, the SLK. Still today Knothe considers it an honour to have helped influence and shape many facets of the S-Class. This also includes his conviction that the S-Class has been a pace-setter and a fine example of safety, driving comfort and luxury.

Knothe is proud of the main mission entrusted to him and successfully mastered by him of having ushered in the development of a completely new S-Class with the W/V 220 model series. It was launched in 1998 and in autumn 2005 was succeeded by the next model series, the W/V 221, which Knothe was also involved with throughout all stages of its development.

The conflicting goals arising from the requirements of the performance specifications were the further improvement of comfort, integrated passive and active safety, and driving dynamics by integrating new systems while at the same time reducing the weight and fuel consumption.

Even today, Knothe takes great satisfaction and pleasure in the fact the he was able to successfully resolve these conflicting goals. Some 15 years earlier, the W/V 140 model series (1991 to 1998) had already set important standards in terms of comfort and safety in this market segment.

It is with satisfaction and pride that Frank Knothe looks back on his time with his only employer, always referring to “we” when speaking of his job at Mercedes-Benz.

Up until the end of his active career on 31 December 2006, he remained Head of Development for the S-Class, the SL-Class and the SLK-Class, and is still in charge of the SLR McLaren. The high points of his work with the S-Class were the W/V 221 model series presented in autumn 2005 and the CL-Coupé, model series C 216, which was unveiled in 2006.

From autumn 2005 to January 2013, over 500,000 vehicles from the W/V 221 model series were sold to customers. Accordingly, Knothe still acts as a consultant for Mercedes-Benz SLS AMG tuning – a job which brings a gleam to his eye as he looks back. His enthusiasm for motoring has remained.

And he still finds it fascinating to follow how, alongside the objective requirements, the subjective, emotional expectations of a Mercedes-Benz car in particular can be met with the appropriate technical and physical solutions.

A key player in the development of the anti-lock braking system (ABS)

Jürgen Paul

Born in Berlin-Köpenick on 2 August 1941

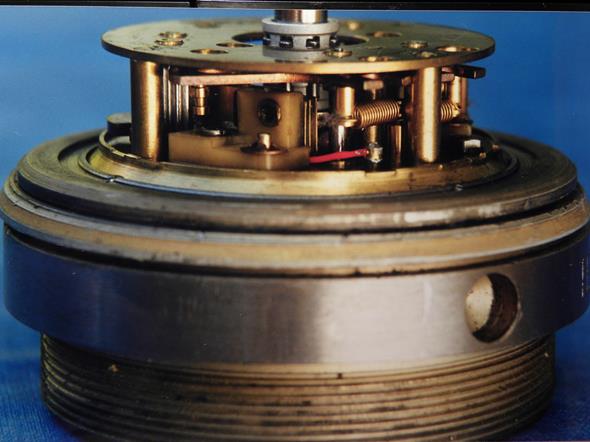

Jürgen Paul was one of the engineers behind the anti-lock braking system (ABS), which marked its series deployment and world premiere in the Mercedes-Benz S-Class in 1978. He was also involved in various subsequent developments based on ABS, such as acceleration slip regulation (ASR) and the ESP® Electronic Stability Program. He was also a pioneer of anti-lock braking systems in motor sport vehicles.

A native of Berlin, Jürgen Paul completed his mechanical engineering studies at the Technical University in West Berlin as a graduate engineer. On 1 January 1969, he began his career at what was then Daimler-Benz AG, first as a clerical assistant for ABS sensors – a area that he would remain involved in throughout his career.

In the years that followed, Paul worked together with the then development partner Teldix to develop ABS based on analogue electronics. In 1970, this system was also given its first public showing in vehicles in the Mercedes-Benz W 115/114 model series – and received a resounding reception by enthusiastic experts and members of the press.

The principle was impressive: this world first maintained a vehicle’s steering capability even when the brakes were fully applied and the system significantly shortened the braking distance, particularly on wet roads.

But it was not yet ready for series production, since the required reliability had not yet been achieved: the conversion to digital electronics under Paul’s leadership began in 1974. It was not until integrated circuits were invented that it became possible to build small, sturdy computers which were capable, for instance, of quickly converting data from the wheel sensors to acceleration data and properly and reliably activating the valves which regulate brake pressure.

In addition, rotating mass sensors were no longer used; instead, wheel acceleration and speed were calculated purely electronically based on signals from the speed sensor. ABS test vehicles and large-scale testing with 100 test vehicles over a total distance of some 35 million kilometres provided evidence of the new system’s operational reliability before its introduction into series production.

This work led to the world premiere of series-production ABS in the S-Class W 116 model series in 1978, developed in partnership with Bosch and initially available as an option at a cost of DM 2,217.60.

Mercedes-Benz passenger cars were first equipped with ABS as standard in 1984. Ten years after the initial introduction, already one million Mercedes-Benz passenger cars with ABS travel the world’s roads. Mercedes-Benz has played a pioneering role in commercial vehicles as well. As early as 1981, for example, ABS was available for pneumatic brakes, developed in partnership with WABCO.

All of the brand’s large touring coaches have been equipped as standard with ABS since 1986, as have all of the brand’s trucks since 1991.

Accordingly, Paul played a key role in the further development of all subsequent stages of ABS for passenger cars, including, for instance, high control accuracy and a more comfortable brake pedal feel during full braking.

Further technical systems which he helped develop were acceleration slip regulation ASR (September 1985), the ESP® driving safety system, first introduced as standard in the S-Class in 1995, and Brake Assist (BAS), fitted as standard in Mercedes-Benz passenger cars from 1996 onwards.

In the early 1990s, when Roland Asch suggested the introduction of ABS in Mercedes-Benz racing cars, Jürgen Paul once again performed pioneering work in adapting the system to the specific requirements of motorsport. In late 1990, the system found its way into the Mercedes-Benz racing cars of the German Touring Car Championship (DTM).

Paul received numerous accolades for his contributions to vehicle safety systems. On 5 June 1979, he received the Safety Award for Engineering Excellence for the development of ABS, which is given out by the United States National Highway Traffic Safety Administration (N.H.T.S.A). On 27 March 1981, he received the “Porsche Award” jointly with the Bosch engineer Heinz Leiber in Vienna, also for the development of ABS.

This was followed on 17 October 1996 by the Prince Michael Road Safety Award, given out since 1987, which he, along with the then technical director of the car supplier Lucas, Heinz Rath, received for the development of Brake Assist (BAS) from the British Prince Michael of Kent.

On 1 July 1994, Jürgen Paul became Center Director for Brakes and Control Systems at Mercedes-Benz Engineering. Just over three years later, on 31 December 1997, he retired.