Modern classics: the S-Class of the W 126 series (1979 – 1991)

- The most successful premium-class saloon in company history

- The Mercedes-Benz S-Class widely considered the best car in the world

- Maximum comfort and outstanding safety

Stuttgart – In September 1979 Mercedes-Benz presented the new S-Class from the W 126 series at the International Motor Show (IAA) in Frankfurt/Main. It proved an instant success, and over its entire production period became one of the most commonly registered of premium-class vehicles worldwide.

It was produced for twelve years until 1991 – an unusually lengthy period. Production statistics illustrate the success of the series. In the US, the impressive figure of more than 127,000 vehicles from the W 126 series were registered (as of September 2009). In the European markets of Germany, France, Italy and the Netherlands combined, the figure was just under 28,000 units.

This also underlined the longevity of this series. Mileages running to several hundred thousand kilometres were not uncommon. All parts were designed for heavy duty use and a long service life. Many customers kept their W 126 vehicles for many years, appreciating the series’ constancy and reliability – even today.

An important role here has been played by the unparalleled life cycle support, for virtually every part is still available today through the Mercedes-Benz service organisation. All this makes the S-Class from the W 126 series a truly sought-after classic. Examples in exceptional condition are on display at Mercedes-Benz Young Classics in Stuttgart, where on a regular basis a number of vehicles are available for purchase or hire.

The Mercedes-Benz S-Class is considered by many to be the world’s best car. Offering superiority in every detail, comfort even on long journeys is taken for granted.

One contemporary chronicler wrote of the 126 series: “Meticulous craftsmanship and impeccable technology, reliability, durability and an undemanding nature, superior performance and unbeatable handling characteristics, with effortless user-friendliness, maximum interior safety on the one hand, and self-evident prestige on the other – all these factors, uniquely combined, provide the hallmark of this simply first-class automobile.” This characterisation still holds true today.

The W 126 series was a perfect concept down to the last detail. This began with the design, which integrated lines of new objectivity that still appear modern and presentable even today. It was the first time that a Mercedes-Benz passenger car had no bumper bars in the classic sense, but instead generously proportioned, plastic-coated bumpers integrated seamlessly into the front and rear aprons. Broad plastic rub strips running along the sides created a visual link between front and rear ends, positioned at bumper height between the wheel arches.

The design also reflected a feature of the day, for one of the most significant design elements of the new S-Class was its reduced aerodynamic drag – part of a series of comprehensive measures to improve fuel consumption. Optimised in the wind tunnel, the body was designed by adhering closely to the laws of aerodynamics, resulting in a much lower drag coefficient of cd=0.36 compared with the W 116 series (cd=0.41).

This, in combination with the use of weight-reducing materials, meant fuel consumption could be cut by approximately 10 percent compared with the predecessor series.

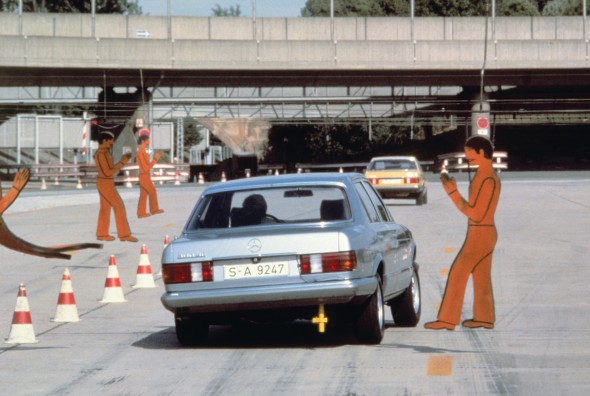

Moreover, the body was designed in line with the latest findings in safety research. Thanks to new design principles, the passenger compartment from the W 126 series was the world’s first production vehicle capable of withstanding an “offset crash” at impact speeds up to 55 km/h.

Safety was in any case – typical of the brand – a central topic at Mercedes-Benz. Airbag and belt tensioner were available for the driver in the W 126 series from 1981 onwards, and following the model refinement package of 1985 an airbag was also introduced for the front passenger.

Three-point seat belts were available on the rear seat bench. Although these features are nowadays commonplace throughout the car industry, they were absolutely innovative at the time and served to demonstrate the innovative strength of the Stuttgart brand. Automatic locking differential (ASD) and acceleration skid control (ASR) helped guarantee optimum power transmission whatever the road surface, thereby providing an added safety bonus.

The range of models available was comprised initially of seven vehicles and two body variants. In addition to the normal version, a lengthened variant was also available, as had traditionally been the case with premium-segment saloons for generations. The customer had the choice of four engines, ranging from the 2.8-litre six-cylinder carburettor unit with 115 kW to the 5.0-litre V8 light-alloy engine with direct fuel injection and 176 kW. Once again a diesel version of the W 126 version was produced exclusively for export to the US, the 300 SD Turbodiesel, which later became the 300 SDL.

A comprehensive model refinement package was carried out in 1985. In addition to a facelift that involved primarily the bumpers, protection side mouldings and wheels, the main focus was on restructuring the engine range. The most spectacular newcomer was a 5.6-litre eight-cylinder unit which generated 200 kW.

The S-Class from the 126 series saw the introduction of the closed-loop catalytic converter. This was optionally available from 1985 and standard-fit equipment from September 1986. Until mid 1989 the customer had a choice, however: he could either order the so-called “catalytic converter retrofit version”, which was delivered without catalytic converter and oxygen sensor, but with the multifunctional mixture preparation and ignition system. These “retrofit versions” could be equipped with the closed-loop catalytic converter without difficulty at a later date.

The sum of all these details made the Mercedes-Benz S-Class from the W 126 series a highly desirable vehicle – even today. At the same time it was one of the most successful premium-class series in the history of the company. During the twelve-year production period, a total of 818,066 saloons left the production workshops in Sindelfingen. The second-hand market is therefore well stocked – putting the special experience of driving a Mercedes-Benz S-Class as a young classic easily within reach.

Model history: The Mercedes-Benz S-Class, W 126 series

• Seven models and four engines available from the outset

• Many design features serve to reduce fuel consumption

• Presented in 1985, the Mercedes-Benz 560 SEL is

top-of-the-range

In September 1979, Daimler-Benz AG presented a new S-Class generation at the International Motor Show (IAA) in Frankfurt. The range of models in the series given the internal designation W 126 was comprised initially of seven vehicles: Choice was from four engines (from the 2.8-litre six-cylinder carburettor unit with 115 kW to the 5.0-litre V8 light-alloy engine with direct fuel injection and 176 kW) and two body variants – in addition to the normal version, a lengthened variant, as had traditionally been the case with premium-segment saloons for generations.

In this case, lengthening of the wheelbase by 140 millimetres was more apparent than otherwise and as usual the extra space served exclusively to increase legroom in the rear and the entry width for the rear doors.

In addition to improving ride comfort and safety, development of the new model series focused on decreasing energy consumption. The use of weight-reducing materials and an aerodynamic body optimized in the wind tunnel (cd= 0.36, compared with cd= 0.41 in the W 116 series) helped the new S-Class achieve a reduction in fuel consumption of around 10-percent over its predecessor models.

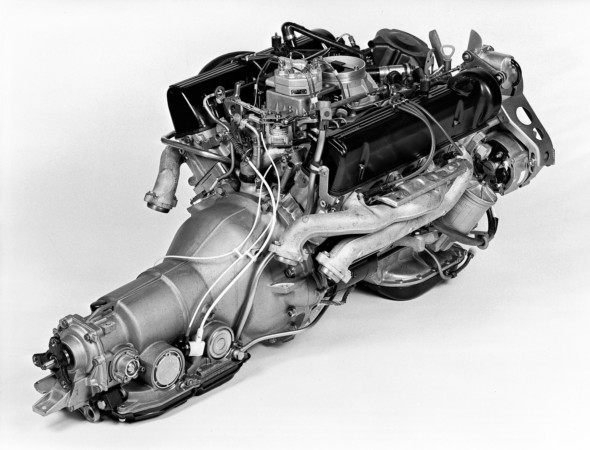

The two eight-cylinder engines of the predecessor series were replaced with two redesigned units with larger displacement and light-alloy crankcase. The 5.0-litre engine, which replaced the 4.5-litre cast iron unit, was already familiar as the power unit from the 450 SLC 5.0, while the 3.8-litre light-alloy engine was developed based on the long-serving 3.5-litre V8 with cast iron block.

With both higher output and reduced weight, the new V8 engines could now achieve improved performance while at the same time using less fuel. The carburettor and injection versions of the 2.8-litre six-cylinder remained in the range unchanged.

Diesel for export

The W 126 series also saw development of a diesel version for export to the USA. Like its predecessors, the 300 SD Turbodiesel offered a turbocharged 3.0-litre five-cylinder engine, though with output now increased by 7.4 kW to 92 kW.

Chassis design was essentially the same as for predecessor models. The new S-Class saloons also featured a diagonal swing-axle at the rear and double-wishbone front suspension with zero-offset steering. The 5.0-litre models were again fitted with the coupled-link axle.

The body design incorporated state-of-the-art findings in safety research. Thanks to its new design principles the passenger compartment was now able to withstand the so-called “offset crash” unscathed at a speed of 55 km/h. The W 126-series saloons were thus the first production cars worldwide to meet the criteria of the frontal offset crash.

Many of the characteristic design elements of the S-Class are to be found beneath the waistline. For the first time, a Mercedes-Benz passenger car had no bumper bars in the classical sense, having instead generously proportioned plastic-coated bumpers that were seamlessly integrated into the car’s front and rear aprons.

Broad lateral protective strips made of plastic created a visual link between front and rear aprons, positioned at bumper height between the wheel arches.

Revised V8 engines

At the IAA in Frankfurt in autumn 1981, two years after the debut of the W 126 series, both V8 units underwent comprehensive revision as part of the “Mercedes-Benz Energy Concept”, a program geared to reducing fuel consumption and harmful emissions. In addition to an increase in compression, the list of improvements included camshafts with modified valve timing, air-bathed injection valves and electronic idle speed control.

Camshafts with modified valve timing enabled maximum torque to be achieved at a lower engine speed and in the case of the 3.8-litre engine torque was even increased. This unit was subjected to particularly thorough revision: In order to achieve a more favourable volume-to-surface ratio, the bore was reduced and the stroke increased. The modified 3.8-litre V8 thus benefited from a slightly larger displacement.

But by way of compensation for their significantly better fuel economy, the two eight-cylinder units were obliged to accept a minor drop in output. In both cases, rear axle ratios were tuned to meet the modified characteristics of the engines and were significantly longer. And the two six-cylinder units also saw a whole series of minor modifications that likewise led to fuel economies, even if these were less dramatic. These measures did not affect power output.

Four years after the launch of the Energy Concept the company carried out a comprehensive model refinement package, so that in September 1985, once again at the IAA in Frankfurt, it was able to introduce a completely revised S-Class line-up. Visual aspects were subjected to moderate revision; first and foremost this affected the bumpers and protective side moulding, but also the wheels, which were changed from 35.56 to 38.10 centimetres. This also brought with it a safety element, since it allowed larger brake discs to be fitted. Top priority, however, was give to the restructuring of the engine range.

Two newly-designed six-cylinder units, which had been premiered nine months earlier in the mid-range W 124 series, now replaced the trusty 2.8-litre M 110 engine. In the place of the carburettor version came a 2.6-litre direct injection unit, while the parallel-developed 3.0-litre unit became successor to the injection variant of the M 110. A new addition to the range was the 4.2-litre V8 engine, developed by increasing the bore of the 3.8-litre unit and now fitted to the S-Class saloon, the SEC coupe and the SL. The 5.0-litre engine was also modified. Now equipped with an electronic ignition system and the electro-mechanically controlled Bosch “KE Jetronic” injection system, it generated an output of 180 kW.

5.6-litre displacement

The most spectacular innovation in the engine range was a 5.6-litre eight-cylinder unit, which was developed by lengthening the stroke of the 5.0-litre V8 and which unleashed an output of 200 kW. If required, an even more highly compressed version was also available that delivered a mighty 221 kW, although it was not possible to combine this unit with a closed-loop emission control system. But even without catalytic converter this so-called ECE version met emissions standards set down by the Economic Commission for Europe. The models fitted with this engine variant – the 560 SEL and 560 SEC – were in their day the most powerful Mercedes-Benz production cars ever built.

All variants in the revised model range – with the exception of the 560 SEL and 560 SEC in the ECE version – were available on request with a closed-loop emission control system with three-way catalytic converter. In each case the series version was the so-called “catalytic converter retrofit version”, for which the vehicle was delivered without catalytic converter and oxygen sensor, but with the multi-functional mixture preparation and ignition system.

These “retrofit versions” could be fitted with the closed-loop catalytic converter without difficulty at a later date. This gave customers maximum flexibility in choosing the moment to convert their vehicle – a not insignificant advantage, given that unleaded gasoline was not universally available at the time. From September 1986 the closed-loop catalytic converter was standard equipment on all Mercedes-Benz passenger car models with gasoline engines; the retrofit versions were available until August 1989 – with a corresponding price discount.

With the introduction of the new model range, the diesel model – which was still reserved exclusively for US export – was replaced by a modified variant. The new 300 SDL was presented with the additional space of the long version and featured an entirely new design of engine. This was based on the familiar 3.0-litre six-cylinder unit from the mid-range W 124 series, although this too was equipped with a turbocharger. The six-cylinder turbodiesel now delivered 110 kW – 44 kW more than the basic version without supercharger and almost 22 kW more than the five-cylinder engine of the predecessor model.

As was expected, the running gear of the facelifted models displayed no fundamental modifications. Nevertheless, the rear axle design was modified in a few details in order to improve ride comfort and reduce engine noise. In addition, all models in the W 126 series were now fitted with 38.10-cm wheels and larger brakes to match. The design of the optional light-alloy wheels – these were only standard equipment on the 560 SEL and 560 SEC – was updated to match those of the compact-class and mid-range model series.

Minor modifications

The other stylistic modifications carried out on the improved models of the W 126 series not only served to update the design, but were also integrated for specific technical reasons. By lowering the aprons it was possible to further reduce front axle lift forces and improve airflow at the rear. This also had the effect of further enhancing directional stability and road adhesion when moving at speed, an aspect of considerable importance with respect to the performance of the new top-of-the-range 560 SEL.

The lateral protective strips were now smooth in design rather than grooved, and like the bumper system they reached down lower and included additional trim on the frame side members. As the 5.6-litre models came with wider 215/65 VR 15 tyres as standard, unlike their lower-powered sister models, front apron and fender beading were modified in shape in order to create the necessary lateral clearance for the front wheels.

In September 1987, when the S-Class encountered an unusually chilly easterly wind in the form of the BMW 750 i, higher-performance variants of all V8 engines were introduced. Compression ratios in all cases were increased to 10:1, and additional measures were taken to improve performance by between six and ten percent depending on the model.

The effect was even clearer in the case of the variants with catalytic converters: By optimizing the emission control equipment the designers succeeded in significantly reducing power loss due to the catalytic converter. The ECE version of the 5.6-litre V8 was discontinued without a replacement, since as a result of the treatment to increase output the catalytic converter retrofit version was now also capable of developing 221 kW.

At the Paris Motor Show in September 1988, the model range was expanded to include the 560 SE from the W 126 series, thus making the 5.6-litre engine available in a saloon with conventional wheelbase.

A new diesel variant

From June 1989 a new variant with diesel engine was produced, although this too was only available in the USA. Production of the previous 300 SDL had already come to an end in September 1987. The 350 SDL model had a new 3.5-litre six-cylinder engine that had been developed by increasing the bore and stroke of the tried-and-tested 3.0-litre unit. The new turbodiesel was designed more for torque than output and, with exhaust gas recirculation and oxidation catalyst, generated 10 kW less than its predecessor in spite of the larger displacement.

But the 350 SDL’s 100 kW was more than adequate, especially given the speed limits that applied throughout the USA. Maximum torque was increased by almost 15 percent and was reached at just 2000/min. In June 1990 the 350 SD with a conventional wheelbase was introduced to go alongside the 350 SDL.

As was the case with the predecessor series W 116, the eight-cylinder W 126 models were also available as armoured variants. Protection design had been further perfected after intensive development work and a total of 1,465 units were produced. Two 500 SEL models are of particularly interest here, both with a wheelbase extended by 200 millimetres and roof raised by 30 millimetres. The first of these was built in January 1983 and served as an additional representational vehicle in the company’s own car pool. The second was built on commission from the Vatican for the Holy Father and handed over to Pope John Paul II in August 1985.

As successors to the W 126 series, eight W 140 series saloons were introduced at the Geneva Motor Show in March 1991. Although the new models went into production only a month later, the plant continued to turn out saloons of the 126 series for export for a while.

Production of most variants came to an end between August and October 1991, although the last few armoured models did not come off the production line until April 1992. During the entire 12-year production period a total of 818,066 saloons left the production lines in Sindelfingen, 97,546 of them with diesel engines. That made the W 126 the most successful premium-class series in the history of the company.