Sensotronic Brake System SBC

Sensotronic Brake Control (SBC) is the name given to an innovative electronically controlled brake system which Mercedes-Benz will fit to future passenger car models.

With Sensotronic Brake Control, electric impulses are used to pass the driver’s braking commands onto a microcomputer which processes various sensor signals simultaneously and, depending on the particular driving situation, calculates the optimum brake pressure for each wheel.

As a result, SBC offers even greater active safety than conventional brake systems when braking in a corner or on a slippery surface.

A high-pressure reservoir and electronically controllable valves ensure that maximum brake pressure is available much sooner.

Moreover, the system offers innovative additional functions to reduce the driver’s workload.

[adsense]These include Traffic Jam Assist, which brakes the vehicle automatically in stop-and-go traffic once the driver takes his or her foot off the accelerator.

The Soft-Stop function – another first – allows particularly soft and smooth stopping in town traffic.

To turn to the technical side: when drivers hit the brake pedal today, their foot moves a piston rod which is linked to the brake booster and the master brake cylinder.

Depending on the pedal force, the master brake cylinder builds up the appropriate amount of pressure in the brake lines which – in a tried and tested interaction of mechanics and hydraulics – then presses the brake pads against the brake discs via the wheel cylinders.

By contrast, in the Mercedes-Benz Sensotronic Brake Control, a large number of mechanical components are simply replaced by electronics.

The brake booster will not be needed in future either.

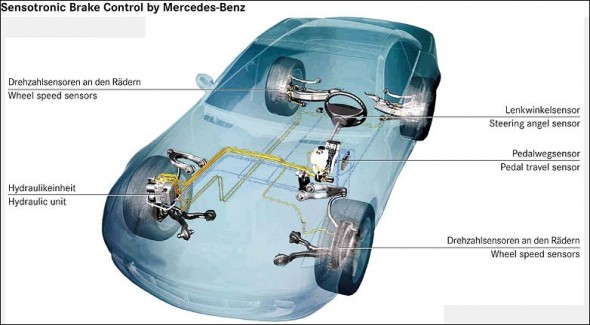

Instead sensors gauge the pressure inside the master brake cylinder as well as the speed with which the brake pedal is operated, and pass these data to the SBC computer in the form of electric impulses.

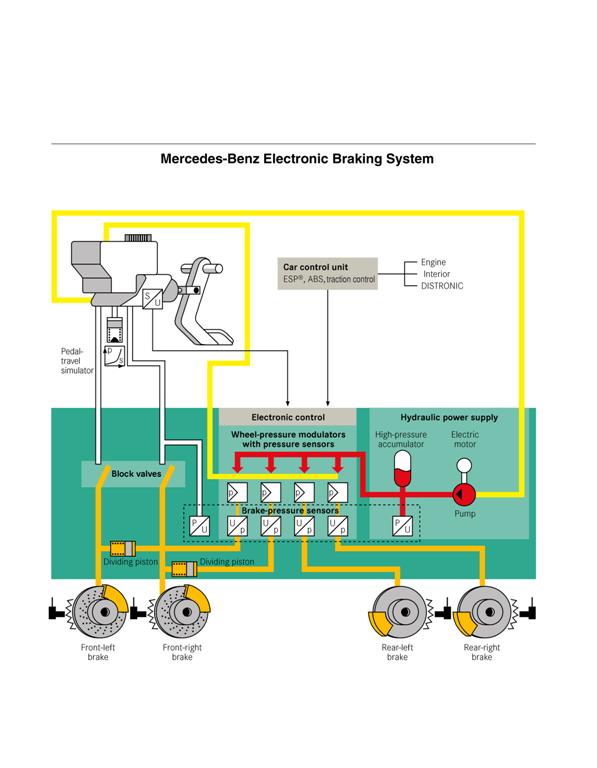

To provide the driver with the familiar brake feel, engineers have developed a special simulator which is linked to the tandem master cylinder and which moves the pedal using spring force and hydraulics.

In other words: during braking, the actuation unit is completely disconnected from the rest of the system and serves the sole purpose of recording any given brake command.

Only in the event of a major fault or power failure does SBC automatically use the services of the tandem master cylinder and instantly establishes a direct hydraulic link between the brake pedal and the front wheel brakes in order to decelerate the car safely.

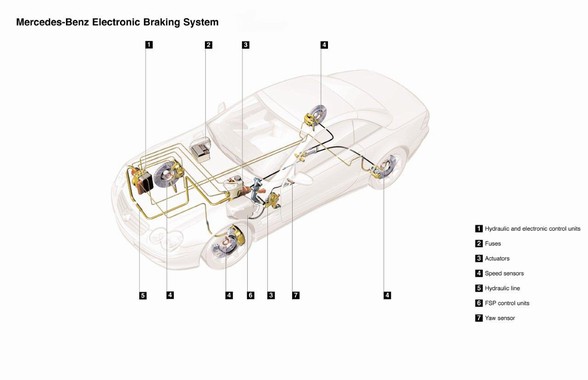

The central control unit under the bonnet is the centrepiece of the electrohydraulic brake.

This is where the interdisciplinary interaction of mechanics and electronics provides its greatest benefits – the microcomputer, software, sensors, valves and electric pump work together and allow totally novel, highly dynamic brake management:

In addition to the data relating to the brake pedal actuation, the SBC computer also receives the sensor signals from the other electronic assistance systems.

For example, the anti-lock braking system (ABS) provides information about wheel speed, while Electronic Stability Program (ESP®) makes available the data from its steering angle, turning rate and transverse acceleration sensors.

The transmission control unit finally uses the data highway to communicate the current driving range.

The result of these highly complex calculations is rapid brake commands which ensure optimum deceleration and driving stability as appropriate to the particular driving scenario.

What makes the system even more sophisticated is the fact that SBC calculates the brake force separately for each wheel.

The high-pressure reservoir contains the brake fluid which enters the system at a pressure of between 140 and 160 bar.

The SBC computer regulates this pressure and also controls the electric pump which is connected to the reservoir.

This ensures much shorter response times than on conventional brake systems. Yet another advantage: full braking power is available even when the engine is switched off.

The hydraulic unit mainly comprises four so-called wheel pressure modulators. They mete out the brake pressure as required and pass it onto the brakes.

In this way it is possible to meet the microcomputer’s stipulations while each wheel is slowed down separately in the interests of driving stability and optimum deceleration.

These processes are monitored by pressure sensors inside the wheel pressure modulators.

The main performance characteristics of Sensotronic Brake Control include the extremely high dynamics during pressure build-up and the exact monitoring of driver and vehicle behaviour using sophisticated sensors.

Take the example of the emergency brake: SBC already recognises the driver’s rapid movement from the accelerator onto the brake pedal as a clue to an imminent emergency stop and responds automatically: with the aid of the high-pressure reservoir, the system increases the pressure inside the brake lines and instantly presses the pads onto the brake discs so that they can get a tight grip the moment the driver steps onto the brake pedal.

As a result of this so-called prefilling of the brake system, the stopping distance of an SBC-equipped sports car from a speed of 120 km/h is cut by around three per cent compared to a car featuring conventional braking technology.

Thanks to electrohydraulic back-up, the performance of Brake Assist is also improved further.

If this system issues the command for an automatic emergency stop, the quick pressure build-up and the automatic prefilling of the wheel brakes leads to a shorter braking distance.

[adsense]It is not just in emergency braking that Sensotronic Brake Control proves its worth, but also in other critical situations – for example, when there is a risk of swerving.

Under such conditions, the system interacts with the Electronic Stability Program (ESP®) which keeps the vehicle safely on course through precise braking impulses at all wheels and/or by reducing engine speed.

SBC once again offers the benefits of greater dynamics and precision: thanks to the even faster and more accurate braking impulses from the SBC high-pressure reservoir, ESP® is able to stabilise early and comfortably a vehicle which is about to break away.

This is evident, for example, from the results of the VDA lane-change test which suspension engineers use to simulate a quick obstacle-avoidance manoeuvre and to demonstrate the high capabilities of the Electronic Stability Program.

In conjunction with SBC, ESP® works even more effectively and significantly reduces vehicle swerving through quick and precise braking impulses.

At the same time the driver’s steering effort is reduced.

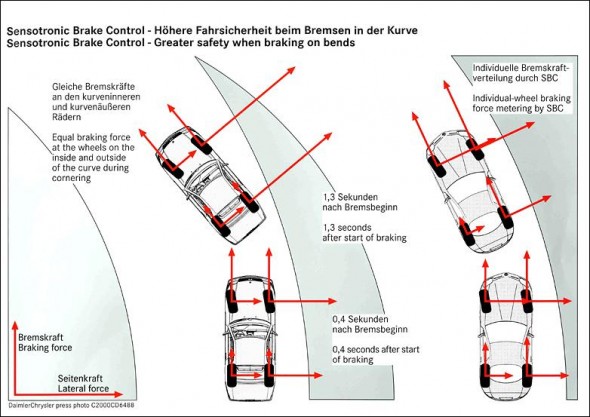

Even when braking in corners, SBC also offers more safety than a conventional brake system.

This is where the variable and targeted brake force distribution is of particular advantage to actively influence the car’s compliance steer.

While conventional brake systems always mete out the brake pressure equally to the inner and outer wheels, SBC offers the possibility of assigning brake forces in a way appropriate to the situation.

Hence the system will automatically increase the brake pressure at the outer wheels because the higher vertical forces also allow them to transfer greater brake forces.

At the same time the brake forces at the inner wheels are reduced to provide the higher cornering forces needed to stay on course.

The result is a more stable braking behaviour along with optimum deceleration values.

With the innovative Sensotronic Brake Control Mercedes engineers still stick to the proven principle of a variable brake force control for the front and rear axles.

They program the system in such a way that, when slowing down from a high speed, the larger part of the brake force continues to act on the front axle.

This prevents a potentially hazardous overbraking of the rear axle. At low speeds or during partial braking, the system automatically increases the brake force share at the rear axle to improve brake system response and achieve even wear and tear of the brake pads.

Both the separation of the SBC pedal from the rest of the brake system and the proportional pressure control using mechatronics serve to increase brake comfort – particularly during sharp deceleration or when the anti-lock braking system is operational.

The usual vibration of the brake pedal when ABS sets in does not occur, which, Mercedes engineers have found, is not only a comfort feature of the new system but also offers measurable safety benefits.

Their research in DaimlerChrysler’s Berlin driving simulator has revealed that almost two thirds of all drivers are startled when ABS pulsation sets in: they do not increase the brake force further and are even prone to taking their foot off the brake pedal for a short while, thereby lengthening the stopping distance of their vehicle – in the driving simulator by an average of 2.10 metres during ABS braking from 60 km/h on a snow-covered road surface.

Sensotronic Brake Control offers additional advantages in everyday driving situations – when slowing down ahead of traffic lights, in the wet, in traffic jams or hill starts: The so-called Soft-Stop function of the SBC software ensures particularly gentle and smooth stopping which provides significant comfort benefits particularly around town when you need to slow down frequently for traffic lights.

On a wet road surface the system metes out short brake impulses at regular intervals to ensure that the water film on the brake discs dries off and that SBC can always operate with optimum effectiveness.

This automatic dry-braking function is activated at regular intervals when the car’s windscreen wipers are running.

The driver does not even notice these ultra-precise brake impulses.

The Sensotronic Brake Control also incorporates a so-called Traffic Jam Assist function, which is activated using the cruise control stalk while the car is stationary.

The benefit is that during stop-and-go traffic drivers only need to use the accelerator pedal; once they take their foot off the accelerator, SBC slows down the car to standstill at a steady rate of deceleration.

The Traffic Jam Assist facility can remain operational up to 60 km/h and switches off automatically at higher speeds.

On hills or steep drives the Sensotronic Brake Control Drive-Away Assist prevents the car from rolling backwards or forwards – stepping onto the brake pedal quickly but sharply is all it takes to activate the brake.

If the driver accelerates, the Drive-Away Assist releases the brake and allows the car to drive off smoothly.

- Electrohydraulic high-pressure brake for future Mercedes models

- Additional functions like Traffic Jam Assist and Drive-Away Assist for even greater comfort

- Mercedes-Benz a brake technology pioneer yet again

Sensotronic Brake Control (SBC) is the name given to an innovative electronically controlled brake system which Mercedes-Benz will fit to future passenger car models.

Following on from the Mercedes innovations ABS, ASR, ESP® and Brake Assist, this system is regarded as yet another important milestone to enhance driving safety.

With Sensotronic Brake Control electric impulses are used to pass the driver’s braking commands onto a microcomputer which processes various sensor signals simultaneously and, depending on the particular driving situation, calculates the optimum brake pressure for each wheel.

As a result, SBC offers even greater active safety than conventional brake systems when braking in a corner or on a slippery surface.

A high-pressure reservoir and electronically controllable valves ensure that maximum brake pressure is available much sooner.

Moreover, the system offers innovative additional functions to reduce the driver’s workload.

These include Traffic Jam Assist, which brakes the vehicle automatically in stop-and-go traffic once the driver takes his or her foot off the accelerator.

The Soft-Stop function – another first – allows particularly soft and smooth stopping in town traffic.

Mechatronics – a new term is gaining popularity within the automotive industry and is rapidly developing into the catchword of a quiet technological revolution which in many fields stands century-old principles on their head.

Mechatronics brings together two disciplines which in many cases were thought to be irreconcilable, namely mechanics and electronics.

Hence automobile functions which hitherto worked purely mechanically and partly with hydraulic assistance will in future be controlled by high-performance microcomputers and electronically controllable actuators.

These either replace the conventional mechanical components or else enhance their function.

[adsense]The mechatronic interplay therefore opens up hitherto inconceivable possibilities to further raise the safety and comfort levels of modern passenger cars.

For example: it was only thanks to mechatronics that an electronically controlled suspension system which instantly adapts to prevailing conditions when driving off, braking or cornering — thus providing a totally new driving experience — became a reality.

In 1999 Mercedes-Benz launched this system under the name Active Body Control (ABC) in the flagship CL coupé, thereby signalling the advent of a new era of suspension technology.

This electronically controlled suspension system will quickly be followed by the electronic brake system: Mercedes-Benz and Bosch have teamed up on this benchmark development project which will shortly enter into series production at the Stuttgart automobile brand under the name Sensotronic Brake Control — or SBC for short.

It turns the conventional hydraulic brake into an even more powerful mechatronic system. Its microcomputer is integrated into the car’s data network and processes information from various electronic control units.

In this way, electric impulses and sensor signals can be instantly converted into braking commands, providing a marked safety and comfort gain for drivers.

Brake pedal: electronics instead of a vacuum

To turn to the technical side: when drivers hit the brake pedal today, their foot moves a piston rod which is linked to the brake booster and the master brake cylinder.

Depending on the pedal force, the master brake cylinder builds up the appropriate amount of pressure in the brake lines which – in a tried and tested interaction of mechanics and hydraulics – then presses the brake pads against the brake discs via the wheel cylinder.

In the Mercedes-Benz Sensotronic Brake Control, by contrast, a large number of mechanical components are simply replaced by electronics.

The brake booster will not be needed in future either. Instead sensors gauge the pressure inside the master brake cylinder as well as the speed with which the brake pedal is operated, and pass these data to the SBC computer in the form of electric impulses.

To provide the driver with the familiar brake feel engineers have developed a special simulator which is linked to the tandem master cylinder and which moves the pedal using spring force and hydraulics.

In other words: during braking the actuation unit is completely disconnected from the rest of the system and serves the sole purpose of recording any given brake command.

Only in the event of a major fault or power failure inside the 12V vehicle battery does SBC automatically use the services of the tandem master cylinder and instantly establishes a direct hydraulic link between the brake pedal and the front wheel brakes in order to decelerate the car safely.

Control unit: pressure modulators for each wheel

The central control unit under the bonnet is the centrepiece of the electrohydraulic brake.

This is where the interdisciplinary interaction of mechanics and electronics provides its greatest benefits – the microcomputer, software, sensors, valves and electric pump work together and allow totally novel, highly dynamic brake management:

In addition to the data relating to the brake pedal actuation, the SBC computer also receives the sensor signals from the other electronic assistance systems.

For example, the anti-lock braking system (ABS) provides information about wheel speed, while ESP® makes available the data from its steering angle, turning rate and transverse acceleration sensors.

The transmission control unit finally uses the data highway to communicate the current driving range.

The result of these highly complex calculations is rapid brake commands which ensure optimum deceleration and driving stability as appropriate to the particular driving scenario.

What makes the system even more sophisticated is the fact that SBC calculates the brake force separately for each wheel.

The high-pressure reservoir contains the brake fluid which enters the system at a pressure of between 140 and 160 bar.

The SBC computer regulates this pressure and also controls the electric pump which is connected to the reservoir.

This ensures much shorter response times than on conventional brake systems.

Yet another advantage: full braking power is available even when the engine is switched off.

The hydraulic unit mainly comprises four so-called wheel pressure modulators. They mete out the brake pressure as required and pass it onto the brakes.

In this way it is possible to meet the microcomputer’s stipulations while each wheel is slowed down separately in the interests of driving stability and optimum deceleration.

These processes are monitored by pressure sensors inside the wheel pressure modulators.

Emergency braking: stopping distance reduced by up to three per cent

The main performance characteristics of Sensotronic Brake Control include the extremely high dynamics during pressure build-up and the exact monitoring of driver and vehicle behaviour using sophisticated sensors.

Mercedes-Benz is thus moving into new dimensions of driving safety.

Take the example of the emergency brake: SBC already recognises the driver’s rapid movement from the accelerator onto the brake pedal as a clue to an imminent emergency stop and responds automatically: with the aid of the high-pressure reservoir, the system increases the pressure inside the brake lines and instantly presses the pads onto the brake discs so that they can get a tight grip the moment the driver steps onto the brake pedal.

As a result of this so-called prefilling of the brake system, the stopping distance of an SBC-equipped sports car from a speed of 120 km/h is cut by around three per cent compared to a car featuring conventional braking technology.

Thanks to electrohydraulic back-up, the performance of Brake Assist is also improved further.

If this system issues the command for an automatic emergency stop, the quick pressure build-up and the automatic prefilling of the wheel brakes leads to a shorter braking distance.

Driving stability: precise braking impulses for perfect ESP® performance

It is not just in emergency braking that Sensotronic Brake Control proves its worth, but also in other critical situations – for example, when there is a risk of swerving.

Under such conditions, the system interacts with the Electronic Stability Program (ESP®) which keeps the vehicle safely on course through precise braking impulses at all wheels and/or by reducing engine speed.

SBC once again offers the benefits of greater dynamics and precision: thanks to the even faster and more accurate braking impulses from the SBC high-pressure reservoir, ESP® is able to stabilise early and comfortably a vehicle which is about to break away.

This is evident, for example, from the results of the VDA lane-change test which suspension engineers use to simulate a quick obstacle-avoidance manoeuvre and to demonstrate the high capabilities of the Electronic Stability Program.

In conjunction with SBC, ESP® works even more effectively and significantly reduces vehicle swerving through quick and precise braking impulses.

At the same time the driver’s steering effort is reduced. Thanks to SBC and ESP® he or she will have even less difficulty keeping the car on course.

Braking in corners: greater safety thanks to variable brake force distribution

Even when braking in corners, SBC also offers more safety than a conventional brake system.

This is where the variable and targeted brake force distribution is of particular advantage to actively influence the car’s compliance steer.

While conventional brake systems always mete out the brake pressure equally to the inner and outer wheels, SBC offers the possibility of assigning brake forces in a way appropriate to the situation.

Hence the system will automatically increase the brake pressure at the outer wheels because the higher vertical forces also allow them to transfer greater brake forces.

At the same time the brake forces at the inner wheels are reduced to provide the higher cornering forces needed to stay on course.

The result is a more stable braking behaviour along with optimum deceleration values.

With the innovative Sensotronic Brake Control Mercedes engineers still stick to the proven principle of a variable brake force control for the front and rear axles.

They program the system in such a way that, when slowing down from a high speed, the larger part of the brake force continues to act on the front axle.

This prevents a potentially hazardous overbraking of the rear axle. Again SBC is capable of adapting to the prevailing situation.

At low speeds or during partial braking, the system automatically increases the brake force share at the rear axle to improve brake system response and achieve even wear and tear of the brake pads.

Comfort: no pedal vibrations during ABS operation

Both the separation of the SBC pedal from the rest of the brake system and the proportional pressure control using mechatronics serve to increase brake comfort – particularly during sharp deceleration or when the anti-lock braking system is operational.

The usual vibration of the brake pedal when ABS sets in does not occur, which, Mercedes engineers have found, is not only a comfort feature of the new system but also offers measurable safety benefits.

Their research in DaimlerChrysler’s Berlin driving simulator has revealed that almost two thirds of all drivers are startled when ABS pulsation sets in: they do not increase the brake force further and are even prone to taking their foot off the brake pedal for a short while, thereby lengthening the stopping distance of their vehicle – in the driving simulator by an average of 2.10 metres during ABS braking from 60 km/h on a snow-covered road surface.

SBC add-on functions: support systems to reduce driver strain

Sensotronic Brake Control offers additional advantages in everyday driving situations – when slowing down ahead of traffic lights, in the wet, in traffic jams or hill starts:

The so-called Soft-Stop function of the SBC software ensures particularly gentle and smooth stopping which provides significant comfort benefits particularly around town when you need to slow down frequently for traffic lights.

All this is made possible by the higher-precision pressure control thanks to mechatronics.

On a wet road surface the system metes out short brake impulses at regular intervals to ensure that the water film on the brake discs dries off and that SBC can always operate with optimum effectiveness.

This automatic dry-braking function is activated at regular intervals when the car’s windscreen wipers are running.

The driver does not even notice these ultra-precise brake impulses.

The Sensotronic Brake Control also incorporates a so-called Traffic Jam Assist function, which is activated using the cruise control stalk while the car is stationary.

The benefit is that during stop-and-go traffic drivers only need to use the accelerator pedal; once they take their foot off the accelerator, SBC slows down the car to standstill at a steady rate of deceleration.

The Traffic Jam Assist facility can remain operational up to 60 km/h and switches off automatically at higher speeds.

On hills or steep drives the Sensotronic Brake Control Drive-Away Assist prevents the car from rolling backwards or forwards – stepping onto the brake pedal quickly but sharply is all it takes to activate the brake. If the driver accelerates, the Drive-Away Assist releases the brake and allows the car to drive off smoothly.

The future: SBC paving the way for automatic guidance systems

The advent of electronics in brake technology opens up new and promising opportunities to Mercedes engineers – and not only in the disciplines of safety and comfort.

Thanks to SBC they have also moved a considerable way closer to the realisation of their long-term objective, namely to be able to automatically guide the cars of the future along the roads with the aid of video cameras, proximity radar and advanced telematics.

For such autonomous vehicle guidance, the experts need a computer-controlled brake system which automatically acts on the instructions of an electronic autopilot and stops the car safely.

Mercedes cancels by-wire brake system; decision a blow to technology’s future

By JENS MEINERS | AUTOMOTIVE NEWS Mercedes-Benz is discontinuing the twice-recalled Robert Bosch GmbH braking system on the E-Class and CLS-Class sedans next summer in a move that is a blow to automotive brake-by-wire technology.

Mercedes will drop the Sensotronic Brake Control system from the E-Class in June 2006 when it introduces the car’s midterm face-lift.

At about the same time, the E Class-derived CLS also will lose the system. Both cars will have a conventional hydraulic braking system.

“We can now offer all the comforts of SBC in a conventional system,” said a Mercedes insider. “SBC was a very expensive system.”

But the source also acknowledged that customers had lost confidence in the system.

Software failure

The technology eliminates the mechanical link between the driver’s brake pedal and the brakes, substituting an electrical link that actuates the brake calipers.

Customer complaints were linked to the failure of software for the brake system. When the system failed, the hydraulic system took over.

But that resulted in a longer stopping distance and additional brake pedal effort by the driver.

“Statistically, (the Sensotronic Brake Control is) as good as our other braking systems and sometimes better,” the insider said.

“But we cannot get the doubts out of customers’ heads.”Mercedes’ SL roadster and the low-volume SLR McLaren and Maybach supercars will retain the brake system until the end of their life cycles.

It would be too costly to re-engineer those low-volume cars to accommodate a conventional system, a source said.

Sensotronic Brake Control was supposed to highlight Mercedes’ technology leadership. Instead, it created a double blow to the brand’s image.

In May 2004, Mercedes recalled 680,000 vehicles to fix the complex brake-by-wire system.

Then, in March 2005, 1.3 million cars were recalled, partly because of further unspecified problems with the Sensotronic Brake Control system.

million price tag

Bosch has no other customers for the system, which it co-developed over nine years with DaimlerChrysler AG at a cost of 147 million euros, or about million at current exchange rates.

A Bosch spokesman acknowledged that the system has lost some of its competitive edge.

“In 2001 we were far ahead with SBC, but conventional technology has not been standing still,” the spokesman said.

“With the ESP Premium (vehicle stability system), we have all SBC functions in a conventional system.”

SBC STOP

The system offers several additional functions besides a new braking behavior, due to its electronic brain: In stop-and-go traffic the vehicle brakes automatically, when the foot is lifted off the accelerator pedal (“Traffic Jam Assist”).

It can be engaged under 10 MPH, using the the cruise control lever and switches off automatically at higher speeds.

It remains active under 40 MPH. When engaged the instrument cluster indicates “SBC S”. One can also activate it on downhill slopes via cruise control, so the car won’t speed over the set limit. It was deleted starting with MY 2005.

SBC SOFT STOP

is not yet released, though few people are aware of it since Mercedes advertises it already. It might be released lateron.

In city traffic soft-stop supposedly allows soft, jerkless stopping. Not sure if it’s needed since SBC brakes can be modulated well, with good feel.

SBC HOLD

A “drive-away assistant” prevents the vehicle from rolling backwards or forward when starting on a hill or steep incline.

A firm push onto the brake pedal, and the car remains stopped, even when taking the foot off the brake pedal, until the driver accelerates and the vehicle begins to roll.

When set, the instrument cluster indicates SBC HOLD. I like using this function and miss it when switching back to other cars.

As far as I know it was first introduced in the spring of 2003 in the 04 E-class Estate and lateron in the 2004 SLs.

DRY BRAKE

And finally there is the dry brake function. It is always activated when the windshield wipers run.

The system then knows, that it rains and, with short brake pulses unnoticed by the driver, keeps the brake discs always dry and fully functional.

Cars with SBC

Mercedes SL roadster (R230)

Mercedes E-Class sedan (W211) and Estate (S211) until mid 2006

Mercedes E-Class 4matic sedan (W211) and 4matic Estate (S211) until mid 2006

Mercedes SLR (C199)

Maybach 57 and 62 (W240)

Mercedes CLS coupe (C219) until mid 2006

Sensotronic Brake Control: a milestone in braking technology

This electronically controlled system has been introduced into series production cars for the first time following a five-year period of development and testing.

It marks an important milestone in the development of braking technology and pushes open the door to the futuristic world of “by-wire” systems.

This technology communicates the driver’s commands electronically via cable, rather than mechanically or hydraulically, as has traditionally been the case.

If the driver steps on the brake pedal, their foot nudges a piston rod which is connected to the brake booster and the main brake cylinder.

The main brake cylinder then builds up the pressure in the brake connectors in proportion to the force exerted on the brake pedal and this pressure presses against the brake discs using wheel cylinders.

Over decades, this interaction between mechanics and hydraulics has become a proven formula used in all kinds of automobiles.

The Mercedes-Benz Sensotronic Brake Control system signals the dawn of a new era in brake technology.

Electronics take the place of mechanical components and a powerful microcomputer, which is integrated into the data network of the car and processes information from a series of electronic control units, oversees the operation of the system.

The voluminous vacuum-powered brake booster is no longer required and the brake pedal and main brake cylinder merge into a single “activation unit”.

This unit is hydraulically decoupled from the remaining parts of the system by valves and serves merely to record the braking command.

Sensors recognise the pressure in the main brake cylinder and the speed at which the brake pedal is pressed, and pass this data on to the SBC computer in the form of electrical impulses.

In order to still give the driver the familiar feeling of braking, the engineers developed a special simulator, which is coupled with the tandem brake cylinder and controls the pedal using spring pressure and hydraulics.

SBC will only activate the tandem brake cylinder automatically in the event of a serious problem or power loss in the 12-Volt on-board network.

In this eventuality, it instantly forms a direct hydraulic connection between the brake pedal and the brakes on the front wheels, thus allowing the driver to bring the car safely to a halt.

The nerve centre: hydraulics and electronics working as a team

The centrepiece of the new brake system is a hydraulics assembly under the bonnet which also brings together the electronic control unit, wheel pressure modulators, pressure reservoir and electro-pump.

The functioning of this assembly highlights the main advantages of the interdisciplinary interaction of mechanics and electronics.

The microcomputer, software, sensors, valves and electro-pump work together perfectly and allow innovative and highly dynamic braking management:

- The SBC computer collects both the data on the activation of the brake pedal and the sensor signals from other electronic assistant systems. This allows the Anti-lock Braking System (ABS), for example, to deliver information on wheel speed, ESP® to activate its sensors monitoring steering angle, rotational speed and transverse acceleration, and the engine and transmission control units to transmit the data identifying engine braking effect and the gear currently engaged. The result of these highly complex calculations are instantaneous brake commands, which ensure maximum deceleration and driving stability. Perhaps the most impressive part, however, is that SBC calculates the braking force for each wheel individually.

- The high-pressure reservoir contains the brake fluid which is injected into the system under 140 to 160-bar pressure. The SBC computer regulates this pressure and also controls the electro-pump connected to the reservoir. The result are considerably shorter response times compared with conventional braking systems. This unit also has the advantage of providing maximum braking effect even when the engine is switched off.

- The hydraulics unit consists essentially of four wheel pressure modulators. They regulate the braking pressure according to the situation in hand and transfer it to the brakes. The target values generated by the microcomputer are thus achieved and each wheel is braked individually to ensure the greatest possible driving stability and optimal deceleration. Four pressure sensors in the wheel pressure modulators and one pressure sensor each for the hydraulics reservoir and the driver’s braking commands monitor the processes involved.

Emergency braking: faster build-up of pressure equals improved safety

Among the foremost performance characteristics of Sensotronic Brake Control are the extremely fast build-up of pressure and the precise observance of driver and vehicle behaviour by a complex sensory system.

This propels Mercedes-Benz into a new dimension in driving safety.

Emergency braking is a good example of where the benefits lie. If the driver switches his foot quickly from accelerator to brake pedal, SBC recognises the early signs of an emergency situation and reacts automatically.

With the help of the high-pressure reservoir, the system raises the pressure in the brake connectors and instantaneously presses the pads onto the brake discs, which can then spring into action with full force as soon as the brake pedal is pressed.

What this means in practical terms is that the “pre-optimisation” of the braking system reduces the stopping distance of the new SL-Class by some three percent from a speed of 120 km/h.

Electro-hydraulic support has also made Brake Assist more powerful. If the system recognises an emergency situation based on the sudden foot movement of the driver, the brakes are automatically optimised and full braking is engaged to ensure a shorter stopping distance.

Braking around corners: variable brake force distribution responds to the situation in hand

SBC also offers higher levels of safety than a conventional system when braking through corners.

Here the variable brake force distribution can prove particularly helpful in actively controlling the car’s self-steer effect.

Whilst conventional braking systems apply the same brake pressure ratio on the outer and inner wheels when cornering, SBC allows the brake force to be divided according to the situation in hand.

Consequently, the system automatically increases the brake pressure on the outer wheels when cornering, as they produce more brake force by virtue of their greater contact forces.

At the same time, the brake force on the inner wheels is reduced. This increases lateral force on the car, which also plays an important role in keeping it on track.

The result is more stable braking and optimum stopping distances.

The Mercedes engineers have stuck by the trusted principle of different brake force on the front and rear axles with the innovative Sensotronic Brake Control. They programme the system in such a way that the majority of the brake force is placed on the front axle when braking at high speed.

This avoids dangerous over-braking on the rear axle. In this respect, too, SBC adapts to the situation the driver finds themselves in.

At low speeds or when braking lightly, the system automatically increases the proportion of the brake force on the rear axle, in order to improve the response of the braking system and to ensure equal wear on all brake pads.

On wet roads: the brake discs dry out automatically

Sensotronic Brake Control offers further benefits on wet roads. In wet weather, the system injects regular, short brake impulses to ensure that the film of water on the brake discs is wiped off and SBC can work as effectively as possible at all times.

This automatic dry braking function is activated in intervals whenever the car’s windscreen wipers have been running for a certain time.

The brake impulses are precisely calculated so that the driver is not aware of them.

Braking comfort: no vibrations on the pedal

The de-coupling of the SBC pedal from the rest of the braking system and the proportional pressure control improves braking comfort – particularly when braking heavily or when the Anti-lock Braking System cuts in.

The vibrations which normally occur through the brake pedal when ABS intervenes are eliminated.

Mercedes engineers have found that this is not just a comfort-enhancing feature of the new system, but also beneficial from a safety point of view.

Testing in DaimlerChrysler’s driving simulator in Berlin shows that almost two thirds of drivers react with shock when they feel the pulsations of the ABS system.

Consequently, they either do not apply any further pressure on the brake pedal, or take their foot away altogether, meaning that their car takes longer to come to a halt.

The testing in the simulator showed that, in ABS braking manoeuvres at 60 km/h on a snow-covered surface, this type of braking behaviour would result in stopping distances being on average 2.10 metres longer.

The road ahead: SBC takes motoring to a new dimension

With the growing influence of electronics in braking technology, the Mercedes engineers are exploring new and promising avenues in areas beyond just safety and comfort.

Indeed, future generations of SBC will offer additional functions designed to relieve the stress on the driver in different driving situations and to enhance ride comfort.

With SBC, the engineers have also taken another large step towards their goal of guiding the automobiles of tomorrow fully automatically around town and country, with the help of video cameras, distance regulator radar and pioneering telematics.

The new SL-Class points the way to the future of the automobile.