E 300 BlueTEC HYBRID is awarded Environmental Certificate

Stuttgart – At the same time as it celebrates its market launch, the E 300 BlueTEC HYBRID has now also obtained its Environmental Certificate in accordance with ISO standard 14062. This award is based on a Life Cycle Assessment, in which the independent inspectors of TÜV Süd subject the vehicle to comprehensive tests covering the entire life cycle.

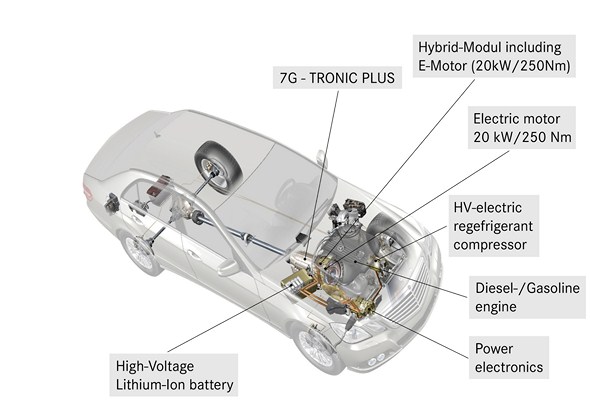

With the new E 300 BlueTEC HYBRID, Mercedes-Benz is launching its first diesel passenger car to feature a hybrid drive. The world’s most economical luxury-class model is rated in energy efficiency class A+ and has now received the coveted Environmental Certificate from TÜV Süd.

The Environmental Certificate and associated explanations will be made available to the public as part of the Life Cycle documentation series, which can be viewed at http://www.mercedes-benz.com.

“After introducing the S 400 HYBRID in 2009, Mercedes-Benz is now setting new standards for luxury-class business vehicles with the E 300 BlueTEC HYBRID”, explains Professor Herbert Kohler, Chief Environmental Officer for Daimler AG. “The modular hybrid technology is opening the way for us to quickly expand other model series with the addition of hybrid models.”

Over its entire life cycle, from production and use over 250,000 kilometres through to recovery, the Mercedes E 300 BlueTEC HYBRID gives rise to 23 percent less CO2 emissions than a comparable E 300 CDI BlueEFFICIENCY.

This is largely a result of the significant reduction in consumption. Compared with the equivalent E 300 CDI BlueEFFICIENCY diesel model, the consumption of the E 300 BlueTEC HYBRID has been reduced from between 6.1 and 5.8 l/100 km to between 4.3 and 4.2 l/100 km (109 g CO2/km) – depending on tyres fitted. This represents a considerable reduction of up to 28 percent.

The E 300 BlueTEC HYBRID meets the mandatory recycling rate of 95 percent by weight that will come into force on 1 January 2015. The future requirements of vehicle recycling were already taken into account at the development stage, and closing material loops plays an important role here, not only in terms of the metals used.

The vehicle makes use of 43 components with a total weight of 41.5 kg, some of which have been produced from recycled plastics.

In addition, the E-Class also features 44 components with a total weight of 21 kg which have been produced using natural materials. The floor in the luggage compartment, for example, is made of a honeycomb cardboard structure, and olive coke is used as an active filter.