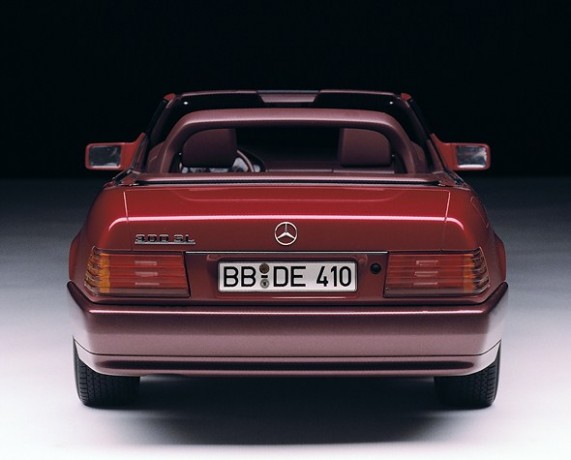

- In its time the safest open-top car in the world

- A milestone in the history of passive safety

- The automatic roll-over bar deploys in 0.3 seconds in the event of danger of overturning

Stuttgart – With the Mercedes-Benz SL, 129 series, presented in 1989, a new era began for open-top driving. Until that moment no car manufacturer had solved the problem involved in cabriolets overturning: the windscreen frame as sole impact point in the event of a roll-over would generally give way and kink at the waistline; there being no other supporting points behind the occupants, these were insufficiently protected and totally exposed to the rigours of the impact.

Accident studies carried out by Mercedes-Benz on their own cabriolets revealed that overturning made up 24 per cent of all accidents, causing the most serious occupant injuries. This was motivation enough for the company to determine to find a better solution.

The only exception to the above statistics was the vehicle design with a fixed, covered roll-over bar, and the vehicle design with a targa roof (ital. targa = [number] plate; roof construction by Porsche since 1965).

However, this solution was out of the question for Mercedes-Benz, as this body design disrupts the cabriolet side line and those who enjoy open-top driving feel it is an unwanted constraint.

The most sophisticated safety for an open-top vehicle

Two mutually-dependent, extremely challenging key criteria had to be met for the new safety concept which was finally implemented in the SL, R 129 series: the roof-drop test and the roll-over test.

The roof-drop test performed at the vehicle development department at Mercedes-Benz was from a height of 50 centimetres, the roll-over test with one-and-a-half to two overturns, from a height of 40 centimetres with the vehicle cast off a sled moving at 30 to 40 kph.

The roll-over stability problem in the case of the R 129 was compounded by its more steeply raked windscreen, whose angle had been increased from 46 (as in model series 107) to 57 degrees in the R 129.

Since the greatest bending load on the A-pillar occurs at the point where it emerges from the vehicle body, and as the pillars may bend – but not break – at that point, intense experiments concerning the choice of materials and the design were necessary.

The solution was an A-pillar design with high-strength sheet metal reinforced by a tube, inserted and cut off at an angle at the top. These decisive improvements, however, were at no point able to replace the need for an additional solution in the form of a roll-over bar.

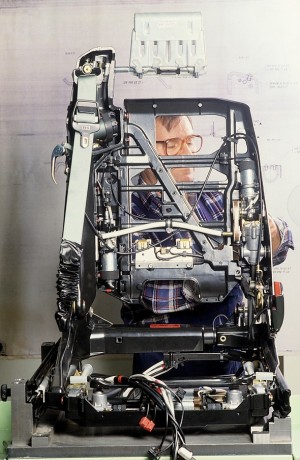

Under the direction of engineer Karl-Heinz Baumann and working through several development stages, a roll-over bar system was developed that consisted of several components. Its core was a U-shaped high-strength hardened and tempered tube, encased in welded half-shells and covered in polyurethane foam.

In addition, there were support and actuation elements to support and deploy the bar, and a multifunction control module that in conjunction with the rear-axle sensors detected an imminent roll-over and triggered the functions of the roll-over bar and seat belts accordingly. This sophisticated system was unique: in the event of an impending overturn it deployed the protective roll-over bar within 0.3 seconds.

The researchers of passive safety at Mercedes-Benz not only took the regulations of individual countries as a basis for the crash safety of a vehicle body, there were also in-house requirements to fulfil. Among these, for example, was the offset crash with a 40 per cent overlap from a speed of 55 kph.

In the mid-eighties, the company assigned more importance to this crash than to the 50 per cent offset crash from a speed of 60 kph which was usual at the time and which of course also had to be passed. The reason: with a 40 per cent overlap the vehicle body structure is subjected to a stronger one-sided load.

The bodywork is compelled to absorb kinetic energy in even greater measure and prevent intrusion, as the engine-transmission assembly cannot help reduce the kinetic energy here.

From model year 1994 onwards, the side-impact test with a “crabbed barrier” became mandatory in the USA. It consisted of an impact with a honeycomb-structured deformable battering ram head, mounted on a striking cart moving at 54 kph and impacting a target vehicle at an angle.

The intention was to provide a simulation for a collision with the “light trucks” so common in the USA. The extreme loads placed on the passenger compartment were absorbed and redirected by transverse reinforcements in the vehicle floor and in the seat system of the R 129 series.

This was how the engineers came to invent the integral seat. From the outset the vehicle which had debuted in 1989 fulfilled these requirements, in other words, a good five years before the regulations came into force.

In addition to the statutory requirement for an impact test with a 100 per cent overlap from a speed of 50 kph, Mercedes-Benz applied further criteria: a 40 per cent overlap at 15 and 50 kph with an impact against a mobile barrier with and without a honeycomb-structured battering head, as well as a rear-end impact with 50 per cent overlap at a speed of 50 kph.

In view of the sum of all these measures, it can be said without fear of exaggeration that the Mercedes-Benz SL, R 129 series, was the safest open-top car in the world at the time of its launch. It was thus also a milestone in the history of passive safety.